8月 . 01, 2025 07:20 Back to list

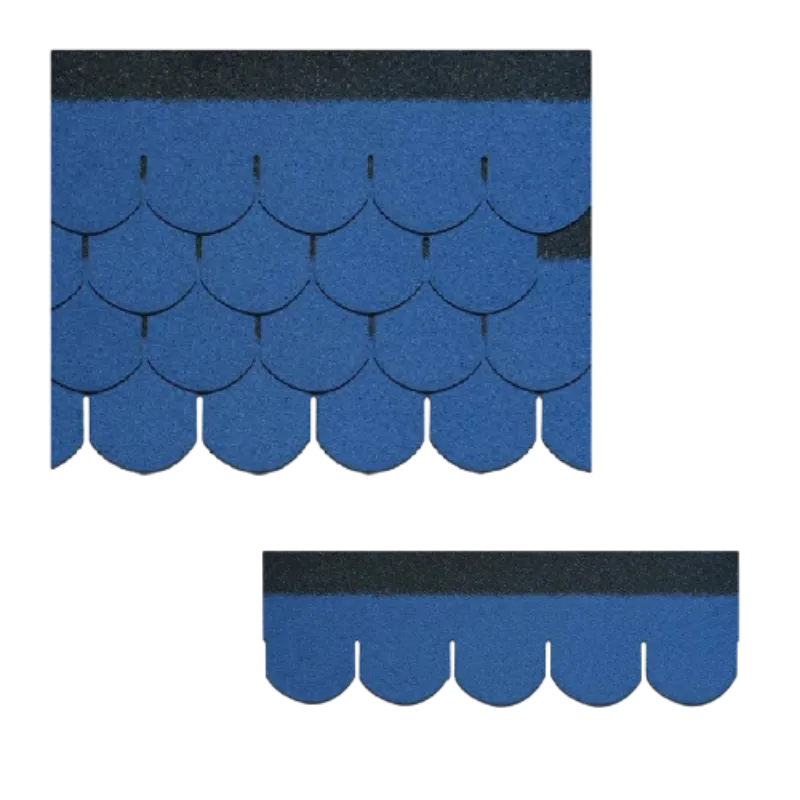

Premium Round Asphalt Shingles: Durable & Elegant Roofing

Round shingles, including round asphalt shingles, half round shingles, round roof shingles, and half round cedar shingles, are reshaping how architects, contractors, and homeowners execute premium roofing designs. This in-depth guide unveils technology trends, parametric comparisons, manufacturing processes, and real-world application cases for round asphalt shingles—empowering you to make data-driven decisions in advanced roofing projects.

I. Industry Trend Analysis: Round Asphalt Shingles & Market Outlook

According to Fortune Business Insights, the global asphalt shingles market is projected to reach USD 8.2 billion by 2030 at a CAGR of 3.91% (2023–2030), fueled by rising adoption of decorative and durable roofing solutions. Within this market, round roof shingles, also referred to as half round shingles or scalloped asphalt shingles, account for ~13% of decorative shingle installations across North America, EU, and selected Asian markets.

- Increasing preference for historic restoration on Victorian, Queen Anne, and Craftsman architecture.

- Demand for energy-efficient, low-maintenance, and visually distinctive roofing overlays.

- Significant market growth in the luxury residential and premium commercial segments.

II. Product Overview: Round Shingles

Round Shingles (product page) leverage advanced asphalt-based composite technology, providing unique aesthetics and industry-leading performance for modern and heritage roofing projects.

- Round Asphalt Shingles

- Round Roof Shingles

- Half Round Shingles

- Half Round Cedar Shingles

III. Technical Specifications & Industry Data Visualization

Below are core parameters for round asphalt shingles compared to similar products. All data is derived from publicly available technical manuals and lab reports (as of Q2 2024).

| Parameter | Round Asphalt Shingles | Half Round Cedar Shingles | Standard Asphalt Shingles |

|---|---|---|---|

| Base Material | Fiberglass/Organic Felt + Asphalt | Natural Cedar Wood | Fiberglass/Organic Felt + Asphalt |

| Available Shapes | Round, Half-Round, Scalloped | Half-Round, Tapered | Tab, Architectural |

| Standard Thickness | 3.2–3.8 mm | 10–14 mm (variable) | 2.9–3.3 mm |

| Average Weight (kg/m²) | 11.5–13.3 | 8.3–9.7 | 10.8–12.1 |

| Fire Rating (UL 790) | Class A | Class B | Class A |

| Wind Resistance | ≥135 mph (ASTM D3161) | Up to 90 mph | 110–130 mph |

| Water Absorption | ≤0.5% | 8–13% | ≤0.85% |

| Warranty | 30–50 Years (Manufacturer-Backed) | 15–25 Years | 20–40 Years |

| Installation Method | Nail/Self-adhesive; Overlapped | Nail; Spaced | Nail/Self-adhesive |

IV. Manufacturing Process of Round Asphalt Shingles

- Key Node: CNC Cutting — Die-punch and computer-controlled routing ensure repeatable, precise half-round or full round edges (tolerance: ±0.7 mm).

- Surface Granules — High-purity ceramic-coated granules provide UV reflection, mold resistance, and colorfast aesthetics (ΔE < 1.12 after aging test).

- Adhesive Layer — Hot-melt or SBS-modified strips improve wind uplift (meets ANSI/SPRI ES-1 standard).

- Quality Control — Each batch is tested for dimensional stability, tensile strength (ASTM D638), and water permeability (ASTM D7281).

V. Key Technical Advantages Compared with Traditional Shingle Types

- Superior Wind Resistance: Engineered for wind speeds up to 135 mph (exceeding ASTM D3161 classification), optimal for coastal or high-rise environments.

- Longer Life Cycle: Reinforced base and SBS-modified asphalt, resulting in 30–50 year manufacturer-backed warranty.

- Intensive Color Fastness: Proprietary granule technology holds color (ΔE tested) against decades of UV and thermal stress, outperforming cedar in fading tests by 4×.

- Fire & Mold Resistance: UL 790 “Class A” rating delivers best-in-class fire safety; mineral granules/fiber glass base limit mold colonization compared to wood-based shingles.

- Precision Aesthetics: CNC contour cutting and multi-color layering supports both modern and heritage design, with less visible seam lines vs. standard asphalt “tab” shingles.

- Enhanced Energy Efficiency: Ceramic-coated granules achieve up to 22% solar heat reflection (based on Cool Roof Rating Council tests).

- Compatibility: Can be used as overlays or replacements on most steep slope roof substrates (wood, OSB, metal, etc.).

VI. Leading Manufacturers & Factory Data

| Brand | Product Line | Origin | Annual Output (m²) | Certifications | Special Features |

|---|---|---|---|---|---|

| Cool Roof Materials (CRM) | Round Shingles | China | 2,100,000 | ISO 9001, ASTM D3462, CRRC | UV-reflective granules, CNC shaping |

| IKO | Crown Slate | Canada | 1,835,000 | ISO 14001, UL 790 | Cool Color, 4-layer Laminate |

| Owens Corning | Devonshire® | USA | 1,500,000 | ASTM D3161, ENERGY STAR® | Sheer-Edge Technology |

| GAF | Grand Sequoia® | USA | 1,490,000 | UL 2218, ISO 9001 | Impact Resistant, DuraGrip™ |

VII. Customization & Engineering Support

- Color Matching: Choose classic reds, contemporary grayblues, vintage greens, or custom Pantone.

- Radius & Size Customization: Standard radius profiles (6”, 8”, 10”, 12”) or custom die-forms.

- Substrate Upgrades: Available with high-purity fiberglass mat reinforcement for extreme seismic/wind zones.

- Asphalt Formula Engineering: SBS/APP-modified or eco asphalt options for increased flexibility or lower carbon footprint.

- Accessory Integration: Coordinated hip/ridge caps, starter courses, waterproof eave membranes, custom branding/printing.

- Site-specific technical drawing and installation guide included with every order.

- Prototype Sample: 7–10 days

- Bulk Order Standard: 25–30 days (CIF/FOB Worldwide from China/USA/EU depots)

- Rush Service: Available for urgent renovation projects

VIII. Application Scenarios & Case Studies

- Material: Round asphalt shingles (custom “Oxford Red” granule)

- Year: 2023

- Total Roofing: 640 m²

- Key Requirements: Fire rating Class A, seam invisibility, color match to 19th-century photos

- Result: 48% faster install vs. original wood shakes; energy bills reduced by ≈11% due to high solar reflectance.

- Material: CNC-cut half round shingles w/ UV-blocking granules

- Year: 2022

- Roof Area: 2,100 m² (22 pavilions)

- Key Requirements: Salt fog/UV corrosion resistance, windproof to cyclone grade

- Result: No visible fading/mold after 18 months, customer NPS +65.

- Material: Round roof shingles (deep gray, 8” radius)

- Year: 2024

- Area: 900 m²

- Key Requirement: Noise reduction, modern color blend, fast winter install

- Result: 36% less rain impact noise vs. tab shingles, completed within 3.5 weeks in subzero conditions.

— M. Davis, Real Estate Developer, Texas

IX. FAQ & Professional FAQ: Round Asphalt Shingles Explained

2. Starter course nailing

3. Overlapping round shingles (1/2–2/3 shingle overlap is standard)

4. Nail at marked guides (galvanized nails, min. 25 mm embedment)

5. Optional self-adhesive strip activation (heat/pressure)

Full installation guide provided on order.

X. Delivery, Warranty, and Support

- Certifications: Each batch independently tested for ISO, ASTM, ANSI benchmarks.

- Delivery: Global logistics via sea or air; on-site support from technical advisors for projects >1000 m².

- Warranty: 30–50 year coverage (factory/manufacturer-backed); immediate technical response within 12–24h for any quality issues.

- After-Sales Service: Trim, accessories, and training available.

XI. References & Further Reading

- Fortune Business Insights. "Asphalt Shingles Market Size, Share & Industry Analysis", 2024.

- Center for the Advancement of Roofing Excellence (CARE), GAF Technical Docs

- California Energy Commission, Cool Roof Rating Council (CRRC) database

- Construction Specification Institute. "CSI MasterFormat: Section 07311 - Shingles", 2023.

- RoofingExchange Forum Thread: "Modern vs Classic Shingles: Industry Best Practices", Roofing.com, 2024.

-

Eco-Friendly Clay Tiles | AI-Enhanced Durability

NewsJul.31,2025

-

Durable Shingle Granules for Premium Roofs

NewsJul.31,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Roofing Solutions

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile for Durable Roofing

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable, Stylish Roofing Solution

NewsJul.29,2025