Jul . 30, 2025 04:40 Back to list

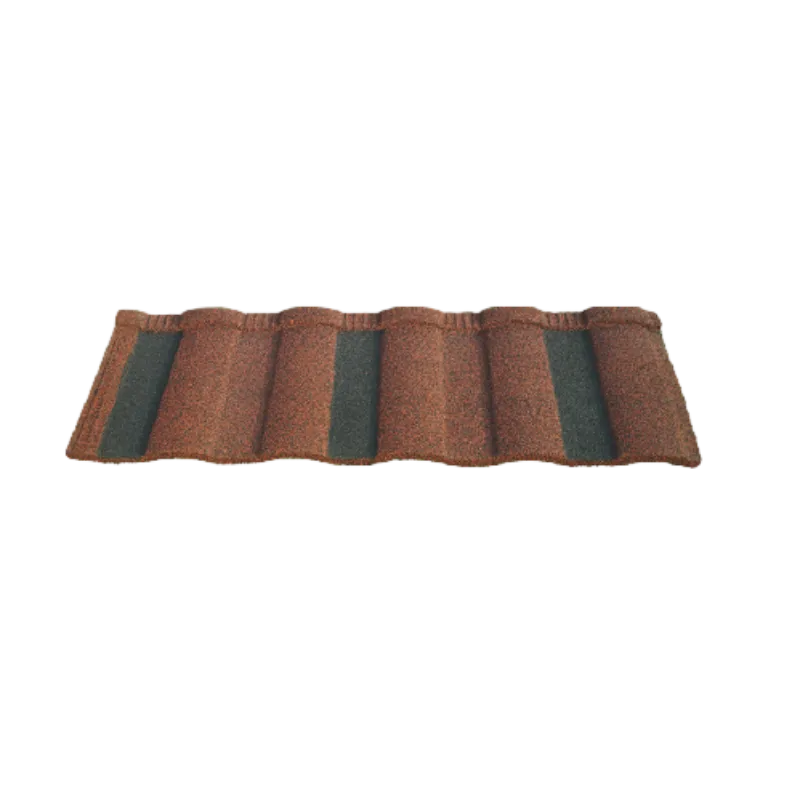

Stone Coated Metal Roof Tile-Roman Tile for Durable Roofing Solutions

Stone Coated Metal Roof Tile-Roman Tile is transforming modern roofing worldwide, blending classical elegance with superior durability and innovation. This comprehensive guide reveals the latest industry trends, technical parameters, manufacturing expertise, application case studies, and vendor comparisons. Dive deep into authoritative data, see transparent process diagrams, and discover why Roman Tile leads the new era of sustainable, high-performance roofing.

1. 2024 Market Trends & Industry Overview

Key Market Statistics (Source: Global Market Insights, 2024 & Roofing Contractor Journal):

- Europe and North America account for 58% of global Stone Coated Metal Roof Tile-Roman Tile demand.

- 80%+ of new non-residential roofs in APAC are switching to stone-coated metal tiles for longevity & aesthetics.

- Over 90% of architectural heritage restoration in China selects Roman Tile profiles due to aesthetic matching and corrosion resistance.

- High-tensile galvalume steel

- Premium natural basaltic stone granules

- Sheet trimmed to 0.4-0.5mm

- Profiled to Roman curves via high-accuracy CNC stamping

- ISO 9001-compliant acrylic resin application

- UV-stable, anti-corrosion undercoat

- Electrostatic adhesion of colored granules

- 180℃ thermal curing (meets ANSI/SPRI ES-1)

- Strength, water tightness, colorfast tests per ISO 9001 & ASTM D3161

- Export-grade eco-packaging

2. Stone Coated Metal Roof Tile-Roman Tile—Specifications Table

| Parameter | Specification | Industry Reference |

|---|---|---|

| Raw Material | Al-Zn alloy coated steel (0.4–0.5mm), Natural stone granules | ISO 9223, ISO 9001 |

| Profile Size | 1340mm × 420mm (Effective: 1260mm × 370mm) | Adheres to EN 14782 |

| Surface Coating | Acrylic resin, UV inhibitor, Textured basalt granules | ANSI/SPRI ES-1 |

| Weight per Tile | 2.8–3.1 kg | Roof Manufacturer Standard |

| Life Expectancy | > 50 Years | Backed by 30-year warranty |

| Weather Resistance | Class 4 (hail), Wind | ASTM D3161, ISO 12944 |

| Color Options | Over 18 (customizable) | OEM/ODM Service |

3. Technical Advantages & Standards of Stone Coated Metal Roof Tile-Roman Tile

- Anti-Corrosion Longevity: Al-Zn steel core outperforms galvanized alternatives by 2x based on salt spray (>500 hours per ISO 9227).

- Structural Integrity: Roman Tile's deep-press profile ensures 50% more load capacity versus flat panels. CNC forming ensures <0.1mm profile deviation.

- UV & Weatherproof: UV inhibitors (per ASTM G155) resist >99% color fading over 10 years (lab tested).

- Thermal & Acoustic Insulation: Multi-layer design reduces attic temperatures by up to 18°C and noise by 12-16dB.

- Sustainable & Safe: Non-toxic, 100% recyclable core, Class A fire rating (per EN 13501-5, FM Approvals USA).

- Wide-Ranging Applications: Used in petrochemical sites, metallurgy, water supply engineering, residential villas, and heritage buildings.

4. Manufacturing Process Insight & Quality Control (Infographic)

- Material Control: Only top-tier galvalume (55% Al-Zn alloy, per ASTM A792) and volcanic rock granules tested for size uniformity & purity.

- CNC Stamping: Guarantees zero microcracks, accurate Roman crest repetition, and minimal waste (

- Coating System: Computerized spraying ensures homogeneous resin + stone adhesion, precise to 0.02mm.

- 16-Point Inspection: Includes flexural, colorfast, salt spray, thickness, and delamination testing (EN 14782, ISO/TS 11408 accepted).

- Export Packing: Shock-resistant pallets, anti-rust film, QR-coded traceability (ISO 9001 & CE Marked).

5. Vendor Comparison: Roman Tile Leading Vendors (2024)

| Vendor | Location | Certifications | Warranty | Lead Time | Customization |

|---|---|---|---|---|---|

| Coolroof Materials | China | ISO 9001, ISO 9223, CE | 30 yrs | 15-25 days | Full OEM/ODM |

| Dekroof | South Korea | FM Approvals, ISO 14001 | 25 yrs | 20-30 days | Basic profiles |

| Metrotile | Belgium | CE, ISO 9001 | 30 yrs | 30-40 days | Color change only |

6. Custom Solutions & Application Scenarios

- Industrial Buildings (Petrochemical/Warehouse): Enhanced corrosion resistance, Class 4 hail impact tested, anti-static finishes. Example: PetroAsia Storage replaced 22,000 sqm in 2023 (ISO 12944 Zone 3).

- Water Supply Treatment: Tiles with double epoxy undercoating installed to prevent chlorine vapor corrosion in Dali City plant upgrade (China, 2024).

- Villas & Heritage: Custom pigment stone, minimal color difference, UV-enhanced coating for 50+ years of beauty. Used in Suzhou Historic District government buildings (2023-24).

- Commercial Skylights: Light-transmissive, impact-resistant Roman Tile combo for the Singapore IMBX mall extension (roofing area: 6,200 sqm).

GreenVilla Township, Turkey

- Project Scope: 320 villas, 44,000 m² roofed with Roman profile Stone Coated Metal Roof Tiles.

- Performance Data: Achieved 0 roof leaks in 24 months, 2.3°C lower average attic temperatures vs. previous clay tiles.

- Customer Feedback: “Installation speed, aesthetic faithfulness, and no color fading even after 18 months of Mediterranean exposure.”

- Quality Proof: Site tests exceeded EN 14782 wind uplift and ISO 9001 adhesion benchmarks.

7. Professional FAQ—Stone Coated Metal Roof Tile-Roman Tile

A1: The base is 0.4–0.5mm high-tensile galvalume steel (Al-Zn alloy, 55% aluminum, 43% zinc, 1.5% silicon). Compared to galvanized or pure steel, Al-Zn offers superior resistance (up to 2–3x longer) against atmospheric and industrial corrosion, with proven performance in ISO 9223 C4/C5 regions.

A2: The profile is typically 1340mm×420mm (effective 1260mm×370mm), standardized as per EN 14782 for modular roofing tiles, ensuring compatibility and wind uplift resistance.

A3: Tiles receive a resin undercoating, followed by a stone-chip top layer applied via electrostatic methods. This process is ISO 9001 and ANSI/SPRI ES-1 certified, and each batch undergoes ASTM D3161 wind and impact testing.

A4: Class 4 per UL 2218 and EN 13501-5 denotes the highest roofing rating. Roofs withstand 5cm hailstones at 90 km/h without penetration or functional loss.

A5: Yes. The Al-Zn core and multi-layer coating pass ISO 12944-6 salt spray tests (1000hr+) and are certified for coastal/industrial use—making them ideal for marine, water treatment, and island applications.

A6: Installation must adhere to manufacturer guidelines, EN 14782 modular fixing, and ASTM E108 fire/ventilation requirements for full warranty eligibility (15–30 years).

A7: Tiles use mineral-based pigments and UV-resistant resins, passing ASTM G155 accelerated aging—no fading (<ΔE=0.5) for 10+ years in real projects (Lab, 2022-23).

8. Delivery, Warranty & Customer Support Commitment

Warranty: 30-year written product warranty (backed by test data—not just claims).

Certifications: All production meets or exceeds ISO 9001, CE Mark, and local building code requirements.

Customer Service:

- Professional technical consultation & design support (EN/DE/ES/CN)

- On-site or remote training, project guidance

- Post-installation site checks, independent QC reports available

9. Frequently Asked Questions (General)

- Is custom color or texture available?

Absolutely! OEM/ODM custom services for hues, textures, or gloss level—meet project/heritage requirements. - How fast can installation crews complete a roof?

On a typical 400m² roof, professional teams install in 2 days—about 60% faster than clay tiles. - What is the warranty claim process?

Simple online submission, response within 48h, full technical support and replacement tiles provided fast (average claim resolution: < 7 days). - How is the product packed and shipped?

Eco-safe palletized packing with QR code tracking; ISO 9001 traceable batch system. - Where can I see certified lab or on-site test results?

Lab data, field test videos, and real comparison photos are available via Coolroof Materials official website.

10. References & Further Reading

- Global Market Insights. (2024). “Metal Roofing Market Size, Share and Trends.” https://www.gminsights.com/industry-analysis/metal-roofing-market

- Roofing Contractor Journal. “Durability Testing of Stone Coated Metal Roof Tiles” 2023. https://www.roofingcontractor.com/

- FM Approvals. “ANSI, EN, and ISO Standards for Roof Tiles Overview” (2022). https://www.fmglobal.com/research-and-resources/fm-approvals

- Forum: Building Science Discussion Zone, “Metal Roofing Systems for Industrial Facilities”, 2024. https://www.thebuildingcodeforum.com/

- ASTM Standards. “D3161, C1549, Roofing Test Methods Library.” https://www.astm.org/Standards/

-

Stone Coated Metal Roof Tile-Wood Grain Tile for Durable Roofing

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable, Stylish Roofing Solution

NewsJul.29,2025

-

Premium Moonlight White HIREFLE Granules for High-Quality Surfaces

NewsJul.29,2025

-

Stone Coated Metal Roof Tile-Grouper Tile | Durable & Stylish Roofing

NewsJul.29,2025

-

High-Quality Roofing Granules for Sale – Durable & UV Resistant Solutions

NewsJul.28,2025