Dec . 10, 2024 23:06 Back to list

Innovative Heat-Resistant Reflective Materials for Enhanced Thermal Management Solutions

The Importance of Heat Resistant Reflective Materials

In today's rapidly advancing world, where temperature fluctuations and heat management play a pivotal role in various industries, the development and utilization of heat resistant reflective materials have become increasingly important. These materials serve as a crucial solution to combat heat build-up, ensuring safety, efficiency, and energy savings across multiple applications.

Understanding Heat Resistant Reflective Materials

Heat resistant reflective materials are specially designed to withstand high temperatures while reflecting radiant heat, significantly reducing thermal transfer. These materials are often composed of advanced polymers, metals, or specialized coatings that enhance their heat resistance and reflectivity. Common examples include aluminum foil, thermal insulating fabrics, and high-temperature coatings that can be applied to surfaces.

Applications in Diverse Industries

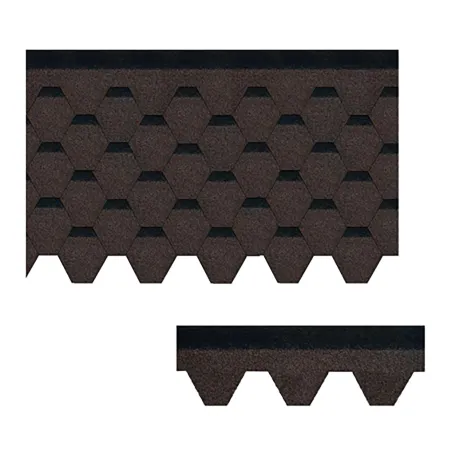

1. Construction and Architecture In the construction industry, heat resistant reflective materials are used in building façades, roofs, and insulation systems. Reflective roofing materials help to lower indoor temperatures by reflecting sunlight away from the building, thereby reducing air conditioning costs. In addition, reflective insulation used in walls and attics not only resists heat transfer but also contributes to improved energy efficiency in homes and commercial buildings.

2. Automotive Industry The automotive sector employs heat resistant reflective materials to enhance passenger comfort and protect critical components. Heat shielding materials, often made from reflective metals like aluminum, are used beneath the hood to divert heat away from sensitive areas, such as wiring and fuel lines. Additionally, reflective window films are applied to car windows to minimize heat absorption, improving climate control inside the vehicle.

3. Aerospace and Defense In aerospace applications, where extreme temperature variations are encountered, heat resistant reflective materials are indispensable. Insulation blankets made from reflective materials are used on spacecraft and satellites to protect delicate instruments and electronics from intense heat generated during re-entry or direct solar exposure. Similarly, in the defense sector, these materials are vital in creating protective gear and equipment that can withstand high temperatures in combat situations.

heat resistant reflective material

4. Consumer Goods Many consumer products also incorporate heat resistant reflective materials. Cooking utensils, such as pans with reflective surfaces, distribute heat evenly, enhancing cooking efficiency. Additionally, reflective materials are increasingly used in outdoor gear like tents and sleeping bags to reflect body heat, improving insulation and comfort for campers and hikers.

Advantages of Using Heat Resistant Reflective Materials

The benefits of heat resistant reflective materials extend beyond mere temperature control. Their use can result in significant energy savings and reduced environmental impact. By minimizing energy consumption for heating or cooling, these materials contribute to lower utility bills and a reduced carbon footprint. Moreover, the longevity and durability of reflective materials ensure that structures and products remain efficient over time, maximizing return on investment.

Challenges and Innovations

Despite their advantages, the development and application of heat resistant reflective materials do pose certain challenges. For instance, achieving the right balance between reflectivity, durability, and cost can be difficult. Innovations in material science continue to address these challenges, leading to the creation of more advanced materials that can withstand even higher temperatures while maintaining their reflective properties.

Research into nanotechnology and coatings is opening new doors for the development of lightweight, highly reflective materials that can serve various industrial needs. These innovations not only promise to enhance performance but also improve the aesthetic qualities of products, catering to consumer preferences for both function and design.

Conclusion

In conclusion, heat resistant reflective materials play a vital role in modern technology and infrastructure. Their ability to withstand high temperatures and reflect heat makes them essential across various industries, from construction and automotive to aerospace and consumer goods. As technological advancements continue, the potential for these materials to revolutionize heat management practices will only grow, leading to safer and more energy-efficient solutions. Embracing these innovations will not only benefit industries but also contribute to a more sustainable future.

-

Top Stone Coated Metal Roofing Suppliers & Manufacturers Durable Stone Coated Metal Tile Solutions

NewsJul.07,2025

-

How Many Bundles of Asphalt Shingles in a Square? Fast Roofing Guide & Tips

NewsJul.07,2025

-

How Long Should a Cedar Shake Roof Last? Expert Guide & Replacement Options

NewsJul.06,2025

-

Premium Expensive Shingles Enhance Your Roof with Lasting Durability and Style

NewsJul.06,2025

-

Roof Shingle Construction Durable & Cost-Effective Asphalt Roof Solutions

NewsJul.06,2025

-

Premium Red 3 Tab Roof Shingles for Durable, Stylish Roofing Solutions

NewsJul.05,2025