Avg . 06, 2025 06:00 Back to list

Architectural Asphalt Shingles | Laminated & Durable

The Evolution of Roofing: Why Laminated Shingles Dominate the Market

The roofing industry has witnessed a significant transformation over the past decades. Gone are the days of simple, flat 3-tab shingles being the only option. Today, the market is led by sophisticated, high-performance materials, with laminated architectural shingles at the forefront. Also known as dimensional or laminate roofing, these products have captured over 80% of the asphalt roofing market in North America, a testament to their superior quality and appeal.

This surge in popularity isn't accidental. Homeowners and contractors are increasingly prioritizing longevity, weather resistance, and curb appeal. A 2023 report by the Asphalt Roofing Manufacturers Association (ARMA) highlighted a 15% year-over-year increase in demand for shingles with high-definition color blends and enhanced shadow lines—features that are hallmarks of asphalt shingles architectural. These products offer a multi-dimensional appearance that masterfully mimics the look of natural materials like slate or wood shakes, but at a fraction of the cost and with significantly less maintenance.

Our flagship product, Laminated Shingles Shingles, embodies this evolution. It is engineered not just to protect, but to enhance. By integrating advanced manufacturing techniques with premium raw materials, we deliver a roofing solution that meets and exceeds the stringent demands of modern construction and extreme weather conditions.

Unpacking the Technology: What Are Laminated Architectural Shingles?

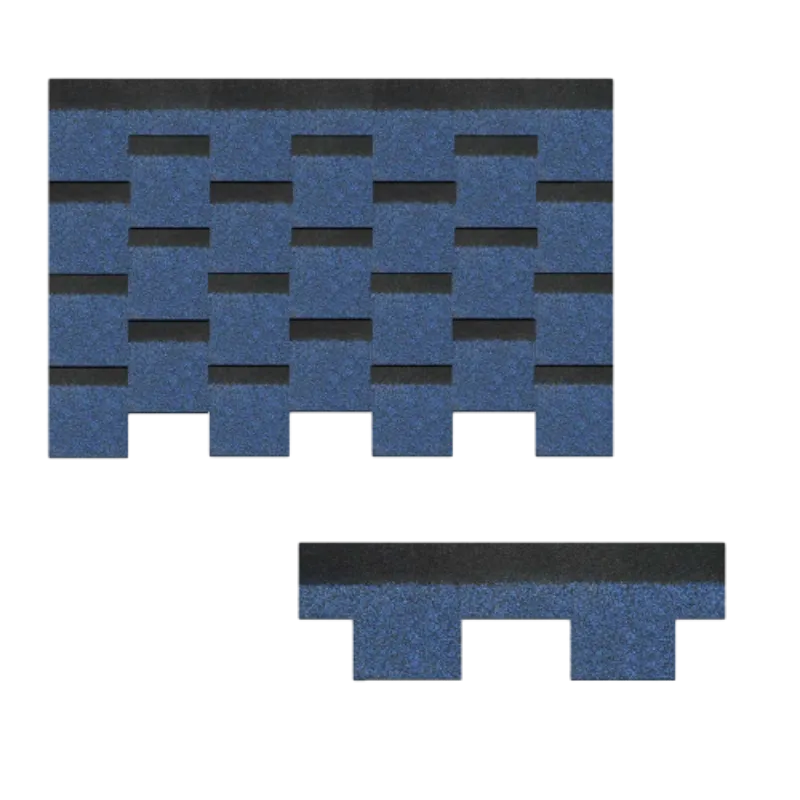

To truly appreciate the value of a laminated comp shingle, it's essential to understand its anatomy. Unlike a traditional 3-tab shingle, which is a single, flat layer, an architectural shingle consists of multiple layers of asphalt and fiberglass mat laminated together. This construction is the key to its enhanced strength and dimensional look.

Core Components and Their Functions:

- Fiberglass Mat (The Backbone): At its core is a high-tensile fiberglass mat, which provides structural integrity, tear resistance, and crucial fire resistance, often achieving a Class A rating per UL 790 standards.

- Weathering-Grade Asphalt (The Shield): The mat is saturated and coated with specially formulated, waterproof asphalt. This layer is engineered to withstand extreme temperature fluctuations without cracking or becoming brittle.

- Ceramic-Coated Granules (The Armor): The top surface is embedded with a dense layer of ceramic-coated mineral granules. These granules serve multiple purposes: they provide the shingle's color and aesthetic appeal, protect the asphalt from UV degradation (which is the primary cause of aging), and add to the shingle's fire resistance. Many modern granules also feature algae-resistant properties (often containing copper) to prevent unsightly black streaks.

- The Lamination Process (The Dimension): The defining feature is the lamination of a second, smaller piece of shingle, often called the "dragon tooth," onto the base shingle. This dual-layer construction creates deep, dramatic shadow lines and a textured, three-dimensional appearance that adds significant character and value to a property.

- Self-Sealant Adhesive Strip: A thermally activated asphalt sealant is applied to each shingle. Once installed and heated by the sun, this strip bonds the courses of shingles together, creating a monolithic, water-tight, and wind-resistant roof deck.

The Manufacturing Process: From Raw Material to a High-Performance Roof

The creation of a superior laminated roof shingle is a marvel of modern manufacturing, blending precision engineering with robust materials science. Each step is meticulously controlled to ensure compliance with international standards like ISO 9001 for quality management and ASTM D3462 for performance. Here’s a detailed look at our state-of-the-art production line for Laminated Shingles Shingles.

Step-by-Step Production Flowchart:

1. Mat Formation

A continuous sheet of non-woven fiberglass mat is created, providing the shingle's core strength.

2. Asphalt Saturation

The mat passes through a saturator, where it's coated with hot, modified asphalt for waterproofing.

3. Granule Application

Ceramic-coated mineral granules are precisely embedded onto the hot asphalt surface.

4. Lamination

The cut "dragon tooth" backer shingle is laminated to the main sheet with high-pressure rollers and adhesive.

5. Cutting & Sealing

The continuous laminated sheet is precision-cut into individual shingles and sealant strips are applied.

6. Quality Control

Shingles undergo rigorous testing for weight, adhesion, and dimensional accuracy (ANSI standards).

Our process is not merely assembly; it's a synthesis of technology and material science. We employ advanced CNC-guided cutters for unparalleled dimensional accuracy and infrared scanners to ensure uniform granule distribution. Every batch is subjected to rigorous quality assurance tests, including tear strength, nail-pull resistance, and granule adhesion tests, ensuring that every shingle that leaves our facility is built to last a lifetime.

Technical Advantages of Laminated Shingles Shingles

Choosing our laminated architectural shingles is an investment in peace of mind. The inherent design and advanced materials provide a suite of benefits that far surpass older roofing technologies. These advantages translate directly into lower lifetime costs, enhanced safety, and superior property value.

Unmatched Wind Resistance

Engineered with advanced sealant technology and a heavier profile, our shingles withstand winds up to 130 mph (209 kph), meeting ASTM D7158 Class H standards, crucial for coastal and high-wind regions.

Extended Lifespan

The dual-layer construction and UV-blocking granules result in lifespans of 30, 40, or even 50 years, backed by industry-leading warranties. This significantly reduces the total cost of ownership compared to 3-tab shingles.

Superior Aesthetics

The dimensional profile creates stunning shadow lines, adding depth and character. Our proprietary color blending technology produces rich, vibrant hues that elevate your property's curb appeal and resale value.

Impact & Algae Resistance

Many of our lines offer Class 4 impact resistance (UL 2218), protecting against hail damage. Copper-infused granules provide a 10-15 year warranty against black streaks caused by blue-green algae.

Maximum Fire Protection

With a fiberglass mat core, our shingles achieve the highest fire rating, Class A from UL 790, providing critical protection for your property and its occupants.

Energy Efficiency

Select "cool roof" colors feature highly reflective granules that can lower roof surface temperatures by up to 50°F, reducing air conditioning costs by 10-15% and mitigating the urban heat island effect.

Performance Metrics: A Data-Driven Comparison

Data provides clarity. To demonstrate the tangible superiority of our asphalt shingles architectural, we've compiled a comprehensive comparison against standard 3-tab shingles and analyzed key performance indicators of our Laminated Shingles Shingles. The numbers speak for themselves.

Product Specification Showdown: Laminated vs. 3-Tab

| Feature | Laminated Shingles Shingles (Architectural) | Standard 3-Tab Shingles | Advantage |

|---|---|---|---|

| Typical Lifespan | 30-50 Years | 15-25 Years | 2x longer service life |

| Wind Resistance Rating | 110 - 130 MPH (ASTM D7158 Class H) | 60 - 80 MPH (ASTM D7158 Class F) | Superior storm protection |

| Weight per Square (100 sq. ft.) | 230 - 280 lbs | 190 - 210 lbs | Greater durability & stability |

| Fire Rating | Class A (UL 790) | Class A (UL 790) | Equal, but with better structural integrity |

| Algae Resistance Warranty | 10 - 15 Years | 5 - 10 Years (or none) | Long-term aesthetic preservation |

| Appearance | Multi-dimensional, shadow lines | Flat, uniform | High-end, premium look |

| Resale Value Impact | High Positive Impact | Neutral / Minor Impact | Increases property value |

Data Visualization of Key Performance Indicators

Wind Resistance Comparison (MPH)

Demonstrates the significant wind uplift protection offered by our laminated shingles compared to standard options.

Material Composition by Weight

Illustrates the robust material makeup, with a high percentage of protective granules and stabilizing asphalt.

Projected Lifespan Curve

Shows the slower degradation curve of laminated shingles, highlighting their long-term value retention.

Customized Roofing Solutions for Diverse Applications

Every project has unique requirements, from the aesthetic goals of a custom home to the stringent performance demands of a commercial facility. We don't just sell shingles; we provide comprehensive roofing solutions tailored to specific application scenarios.

Application Scenarios:

- Residential Homes (Suburban & Luxury): For homeowners, curb appeal is paramount. We offer a vast palette of high-definition colors and profiles to match any architectural style, from rustic wood shake mimics to sleek, modern slate designs. Our products instantly boost a home's value and visual appeal.

- Coastal and High-Wind Zones: Properties in areas prone to hurricanes and severe storms require uncompromising strength. Our 130-MPH wind-rated laminate roofing, combined with a prescribed six-nail installation pattern, provides a robust defense system against the elements, often leading to lower insurance premiums.

- Multi-Family Housing & HOA Communities: For large-scale projects, consistency, durability, and low lifecycle cost are key. We offer project management support, consistent color batches, and products with long warranties to ensure community standards are met and maintenance costs are minimized over the long term.

- Light Commercial & Institutional Buildings: For applications like churches, retail centers, and professional offices, our asphalt shingles architectural offer a cost-effective and aesthetically pleasing alternative to traditional flat roofing systems on sloped sections, providing superior weather protection and design flexibility.

Case Study: The "Seaside Resilience" Residential Project

Challenge: A developer of a 50-unit coastal condominium complex in Florida needed a roofing material that could withstand hurricane-force winds, resist salt-spray corrosion, and combat algae growth, all while providing a premium aesthetic to attract buyers.

Solution: We provided our top-tier Laminated Shingles Shingles with a 130 MPH wind warranty and a 15-year algae resistance guarantee. We collaborated with their architects to select a "Coastal Sand" color blend that complemented the seaside environment.

Result: The completed project not only looks stunning but also qualified for the highest level of insurance credits for wind mitigation. Two years post-installation, after enduring a Category 2 hurricane, every roof remained intact with no shingle loss or damage. The developer reported a 20% faster sales cycle compared to competing properties, attributing a significant portion to the "resilient and beautiful" roofing.

"We exclusively use these laminated architectural shingles on our custom homes. The quality is consistent, the dimensional look is incredible, and our clients are always thrilled with the final result. The 50-year warranty gives them, and us, complete confidence. It's the best asphalt shingles architectural product on the market, period."

Frequently Asked Questions (FAQ)

The primary difference lies in their construction and appearance. A 3-tab shingle is a single, flat piece of asphalt-coated fiberglass cut to look like three separate shingles. A laminated architectural shingle, or laminated comp shingle, is made of two or more layers laminated together. This creates a thicker, more durable shingle with a three-dimensional appearance that mimics natural materials like wood or slate. This construction also provides significantly better wind and impact resistance.

A Class A fire rating is the highest level of fire resistance for roofing materials as tested by Underwriters Laboratories (UL) under the UL 790 standard. It means the roofing system (including underlayment and decking) is effective against severe fire exposure. It demonstrates resistance to the spread of fire, will not produce flying embers, and maintains its structural integrity under intense heat, providing maximum protection for your property.

Wind resistance is tested in a lab according to the ASTM D7158 standard. Shingles are installed on a test deck and subjected to high-velocity upward wind forces to simulate storm conditions. The standard has classifications like Class F (rated to 90 mph) and Class H (rated to 150 mph wind uplift, though warranties are typically for 110 or 130 mph ground speed wind). Our shingles meeting Class H offer superior protection against shingle blow-off during severe weather events.

The granules are hard, dense mineral rock that is crushed and screened for uniformity. They are then coated with a ceramic material in a high-temperature kiln. This process bakes the color permanently onto the granule, ensuring it won't fade over time. For algae resistance, copper-containing particles are blended into the granule mix, as copper is a natural algaecide that prevents the growth of black-streaked blue-green algae.

Generally, yes. Within the category of asphalt shingles architectural, a heavier weight per square typically indicates more asphalt, a thicker fiberglass mat, and a more robust laminated structure. This translates to greater durability, better impact resistance, and improved stability in high winds. While weight is a key indicator of quality, it should be considered alongside other performance ratings like wind and fire classifications.

Proper installation is crucial. Key standards include using the correct number of nails per shingle (typically 4, but 6 in high-wind zones), ensuring correct nail placement, proper shingle offset and exposure, and installing appropriate underlayment, starter strips, and hip & ridge caps. All installations should follow the manufacturer's specific guidelines and local building codes to ensure the roofing system performs as designed and the warranty remains valid.

While some building codes permit installing a second layer of shingles, it is almost always recommended to perform a complete tear-off of the old roof. A tear-off allows for a thorough inspection of the roof deck for rot or damage, ensures a flat, stable surface for the new shingles, and provides the best long-term performance and durability. Installing over an old layer can void the manufacturer's warranty and potentially hide serious structural issues.

Our Commitment to Trust and Authority

Your trust is the foundation of our business. We demonstrate our commitment through transparent practices, robust support, and unwavering quality, ensuring your investment in our Laminated Shingles Shingles is secure.

- Industry Certifications: Our products are rigorously tested and certified to meet or exceed standards from ASTM International, Underwriters Laboratories (UL), and are compliant with the International Building Code (IBC).

- Comprehensive Warranty: We stand behind our laminated architectural shingles with one of the industry's best warranties, covering manufacturing defects for up to 50 years and including non-prorated periods for materials and labor.

- Delivery & Logistics: With a streamlined supply chain, we offer reliable delivery schedules, ensuring your project stays on track. Typical lead times are 5-10 business days, with expedited options available.

- Expert Customer Support: Our team of roofing specialists is available to assist with product selection, technical inquiries, and installation guidance. We provide detailed installation manuals and support for both contractors and homeowners.

References and Further Reading

To further your understanding of asphalt roofing technology, we recommend these authoritative sources:

- Asphalt Roofing Manufacturers Association (ARMA): A leading authority on asphalt roofing, providing technical bulletins, residential roofing guides, and industry research. Visit ARMA

- Roofing Contractor Magazine: An industry publication offering insights into market trends, installation techniques, and new product innovations. Read Roofing Contractor Magazine

- "Technical Bulletin: Algae Discoloration on Roofs" - A detailed explanation from ARMA on the causes and prevention of algae growth on shingles. Access the Bulletin

-

Premium Stone Coated Metal Roof Tiles | Spain Tile

NewsAug.05,2025

-

Types of Roof Shingles: Durable Styles & Materials

NewsAug.04,2025

-

Different 3 Tab Shingles Types | Affordable & Durable Roofing

NewsAug.03,2025

-

Premium Round Asphalt Shingles: Durable & Elegant Roofing

NewsAug.01,2025

-

Eco-Friendly Clay Tiles | AI-Enhanced Durability

NewsJul.31,2025