ستمبر . 23, 2024 21:39 Back to list

Effective Methods for Cooling Iron Sheets in Industrial Applications

The Importance of Cooling Iron Sheets in Industrial Applications

Cooling iron sheets play a critical role in various industrial processes, particularly in the manufacturing and metalworking industries. The cooling of iron sheets is essential to ensure the structural integrity and desired properties of the final product. This process involves controlling the temperature of the sheets after they have been formed or processed, which can significantly influence their mechanical characteristics, durability, and performance.

One of the primary aspects that contribute to the necessity of cooling iron sheets is the reduction of residual stresses. When iron sheets are heated during fabrication processes, such as welding or forging, they undergo thermal expansion. Upon cooling, if the cooling process is uneven or too rapid, it can cause warping or cracking due to the development of residual stresses. By implementing controlled cooling methods, manufacturers can minimize these stresses, ensuring that the sheets retain their shape and mechanical properties.

Moreover, the cooling rate of iron sheets also directly impacts their microstructure. Iron and its alloys can exhibit different behaviors based on how quickly they cool down. For instance, rapid cooling can result in a harder and more brittle structure, while slower cooling can promote toughness and ductility. Understanding this relationship allows metallurgists to optimize the cooling process to produce iron sheets with specific characteristics required for various applications, such as automotive components, construction materials, and machinery parts.

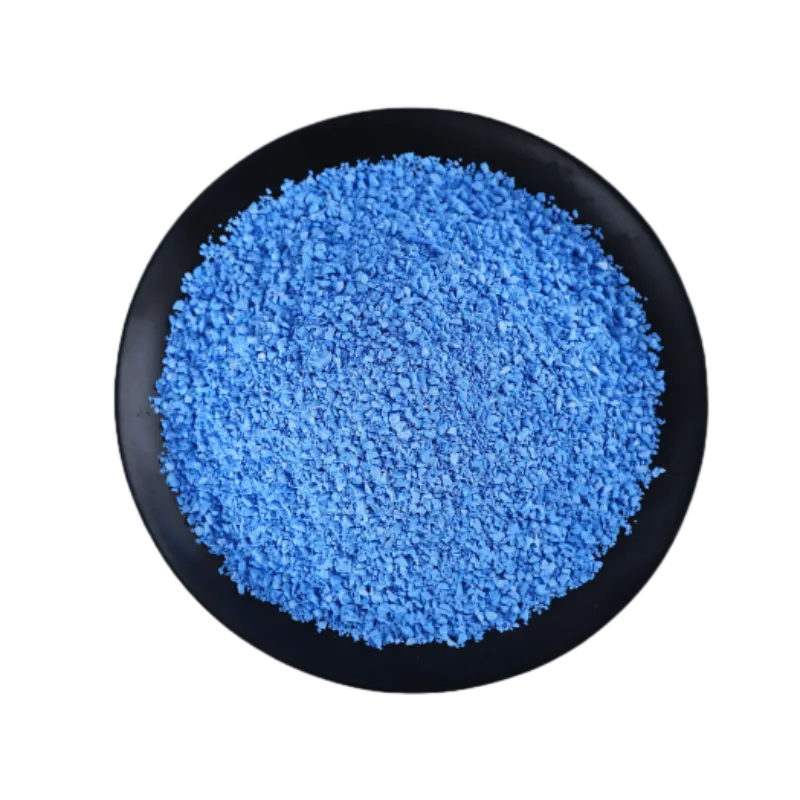

cooling iron sheets

Various methods are utilized for cooling iron sheets, including air cooling, water cooling, and oil quenching. Each method has its advantages and specific applications. For example, air cooling is often employed for larger sheets and less critical components where warping is not a major concern. On the other hand, water cooling may be utilized for smaller components that require rapid cooling to achieve specific hardness levels.

Additionally, advancements in technology have led to the adoption of sophisticated cooling systems, such as controlled atmosphere cooling and the use of cooling towers. These innovations not only improve the efficiency of the cooling process but also help in maintaining consistent quality across batches of iron sheets. This consistency is vital in industries where product specifications are rigorously controlled.

In conclusion, the cooling of iron sheets is a fundamental process in metalworking and manufacturing, directly affecting the quality and performance of the final products. By understanding the importance of cooling and implementing controlled processes, manufacturers can produce iron sheets that meet industry standards and fulfill the demands of various applications. The continual evolution of cooling technologies further enhances the ability of industries to innovate and produce high-quality metal components that drive economic growth and technological advancement.

-

Mosaic Shingles: Durable Roofing, Compare 3 Tab vs Architectural Styles

NewsJul.25,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Elegant Roofing

NewsJul.24,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable & Stylish Roofing

NewsJul.23,2025

-

Durable Tiles Made of Clay for Modern Cladding Solutions

NewsJul.22,2025

-

Stone Coated Roman Tile Metal Roofing - Durable & Elegant

NewsJul.22,2025

-

Premium Roofing Granules for Sale - High Durability & Cost-Saving

NewsJul.21,2025