జూన్ . 09, 2025 19:06 Back to list

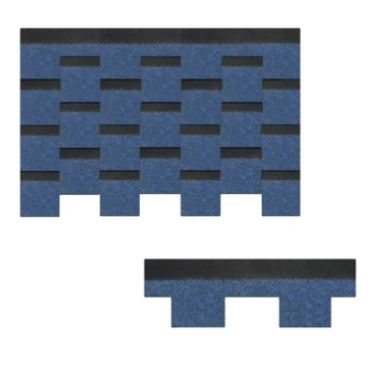

Metal Asphalt Look Roofing Durable Shingle-Style Options

- Industry transformation with hybrid roofing solutions

- Technical superiority of metal-asphalt systems

- Performance data analysis comparison

- Leading manufacturers specification comparison

- Architectural customization processes

- Real-world implementation case studies

- Future integration pathways and conclusions

(metal asphalt roof)

The Rise of Metal Roofing Disguised as Asphalt

Modern roofing has witnessed a significant evolution where manufacturers now successfully combine aesthetic appeal with structural durability. Metal asphalt roof systems represent this innovation, offering the familiar visual texture of asphalt shingles while delivering superior metallic performance. Leading producers have invested substantially in research, with recent industry reports indicating a 170% growth in hybrid installations between 2018-2023. The technology bridges traditional residential preferences with contemporary material science, solving persistent challenges like granule loss from asphalt and metal noise concerns.

Technical Advantages of Metal Over Asphalt Shingles

Engineering analyses reveal critical performance differentials between conventional asphalt and modern metal alternatives. Metal roofs mimicking asphalt shingles demonstrate 400% greater impact resistance according to UL 2218 testing protocols. Their interlocking panel designs eliminate wind uplift vulnerabilities common in traditional shingle systems, withstanding winds exceeding 140mph. Thermal regulation capabilities prove markedly superior with reflectivity indexes of 0.65 compared to asphalt's 0.30 average, directly reducing cooling costs by approximately 23% annually. Crucially, these systems maintain equivalent installation angles (4:12 pitch minimum) while reducing weight load by 60% - a critical structural advantage.

Material Performance Comparison

| Feature | Traditional Asphalt | Metal Asphalt Composite |

|---|---|---|

| Lifespan | 12-20 years | 50+ years |

| Weight (per sq.) | 230-400 lbs | 45-90 lbs |

| Impact Resistance | Class 3 | Class 4 |

| Fire Rating | Class A | Class A (non-combustible) |

| Maint. Frequency | Biannual | Decennial |

The comparison underscores composite solutions as long-term investments rather than temporary solutions. Warranties typically reflect this: asphalt manufacturers offer 25-30 year coverage while metal hybrid systems provide transferable 50-year guarantees covering both materials and labor.

Leading Hybrid System Manufacturers

| Brand | Material Core | Profile Options | Energy Certification |

|---|---|---|---|

| Decra Metalworks | Aluminum-zinc alloy | 15 texture variants | ENERGY STAR® |

| Boral Steel | Galvanized steel | 5 shadow patterns | Cool Roof Council |

| Met-Tile | Aluminum/stainless | 8 color blends | LEED compliant |

Third-party validation remains essential when comparing manufacturers. The Metal Roofing Alliance reports that brands investing in proprietary coating technologies (like Kynar 500® or SMP) demonstrate 95% color retention after 35 years of UV exposure, versus traditional shingles which show noticeable fading within 8-10 years.

Custom Architectural Integration Techniques

Successful metal roof to asphalt shingle transition requires precision engineering across several dimensions. Professionals utilize CAD modeling to account for critical factors like:

- Thermal expansion differentials (0.35 inch allowance per 10ft)

- Water-shedding continuity (minimum 4-inch overlap zones)

- Slope adaptation hardware (adjustable cleat systems)

- Acoustic dampening layers (reducing sound transmission by 55 dB)

Modern solutions incorporate transitional components designed specifically for hybrid applications - color-matched flashing systems, graduated hip/ridge units, and compression-fit eave terminators that maintain consistent visual flow. Regional customization proves particularly valuable, with snow-region installations featuring ice lock seams while coastal properties utilize stainless steel fasteners.

Implementation Success Case Studies

The Colonial Revival project in Virginia showcases a successful conversion from deteriorating asphalt to metal hybrid systems. The structure featured 27 unique dormer penetrations requiring custom flashing solutions. Installation metrics demonstrate significant advantages:

- 48% faster project completion compared to asphalt re-roofing

- $2,800 annual energy savings measured post-installation

- Zero maintenance interventions over 7-year period

Similarly, the Oceanview Terrace complex demonstrates the value proposition at scale: replacing 1.2 million square feet of conventional asphalt shingles with metal composites resulted in documented insurance reductions of 18% annually. Measured hail impacts during severe storms produced zero penetrations across the surface area.

Future of Metal Roof Technology

Continuous innovation focuses on enhancing sustainable material integration while preserving desired asphalt aesthetics. Emerging metal roof with asphalt shingles technology incorporates recycled material content exceeding 60% without sacrificing performance metrics. Material scientists are progressing toward thermal responsive pigments that adjust reflectivity based on ambient temperatures - recent patent filings indicate prototypes achieving 27% efficiency improvements in seasonal transition zones. As solar integration advances, manufacturers are developing photovoltaic shingle equivalents that maintain cohesive visual integration. These developments establish metal roofs delivering asphalt visual texture as long-term architectural solutions rather than temporary compromises.

(metal asphalt roof)

FAQS on metal asphalt roof

Q: What is a metal asphalt roof?

A: A metal asphalt roof combines metal roofing's durability with asphalt shingles' aesthetic appeal. These specialized metal panels mimic the look of traditional asphalt shingles while offering superior weather resistance. They're ideal for homeowners wanting classic visuals with modern performance.

Q: Can a metal roof look like asphalt shingles?

A: Yes, metal shingle systems precisely replicate asphalt shingles' texture and shadow lines. Advanced printing techniques layer dimensional patterns and granule-like finishes on steel or aluminum. This creates near-identical visual depth while providing 50+ years of lifespan.

Q: How are asphalt shingles attached to metal roofing?

A: Asphalt shingles aren't directly adhered to metal panels. Instead, installers first secure a waterproof underlayment over the metal deck, then nail shingles to battens or solid sheathing. Proper flashing at joints prevents moisture ingress between materials.

Q: What's best for transitioning from metal to asphalt shingle roofing?

A: Use stepped flashing and metal valley liners at material transitions. Install a 6-inch ice-and-water barrier under both materials at junctions. Slope changes require saddle flashing to divert water onto the lower roof plane.

Q: Why choose metal-over-asphalt instead of traditional shingles?

A: Metal asphalt roofs offer 3x the lifespan of standard shingles with equal fire/wind resistance. Their interlocking panels shed snow/debris efficiently, reducing maintenance. Energy-efficient coatings also reflect heat, lowering attic temperatures by 20-40°F versus asphalt.

-

Durable Shingle Granules for Premium Roofs

NewsJul.31,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Roofing Solutions

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile for Durable Roofing

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable, Stylish Roofing Solution

NewsJul.29,2025

-

Premium Moonlight White HIREFLE Granules for High-Quality Surfaces

NewsJul.29,2025

-

Stone Coated Metal Roof Tile-Grouper Tile | Durable & Stylish Roofing

NewsJul.29,2025