Aug . 08, 2025 04:00 Back to list

Mosaic Shingles: Style, Durability & Shingle Comparisons

In the evolving landscape of architectural design and building materials, roofing solutions play a pivotal role in defining both the aesthetic appeal and the structural integrity of a property. Among the myriad of options available, mosaic shingles have emerged as a distinctive choice, offering a unique blend of sophisticated aesthetics, exceptional durability, and advanced performance characteristics. This comprehensive guide delves into the intricate world of mosaic shingles, exploring their technical prowess, application versatility, and the cutting-edge manufacturing processes that set them apart in the competitive roofing market.

Current Industry Trends and Market Dynamics in Roofing

The roofing industry is currently experiencing a significant shift towards materials that offer enhanced longevity, superior weather resistance, and improved energy efficiency, alongside compelling visual appeal. Homeowners and commercial developers alike are increasingly prioritizing sustainable and high-performance solutions. According to a recent report by Grand View Research, the global roofing market size was valued at USD 116.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030, driven by rapid urbanization, increasing demand for sustainable housing, and a focus on renovation and repair activities. Within this growth, premium asphalt shingles, including specialized designs like mosaic shingles, are seeing increased adoption due to their balance of cost-effectiveness, performance, and aesthetic flexibility.

The demand for roofs that can withstand extreme weather events—from high winds and heavy snowfall to intense UV radiation—is also escalating. This trend directly benefits products like mosaic shingles, which are engineered with advanced layering and robust materials to offer superior protection. Furthermore, the push for energy efficiency is driving innovation, with "cool roof" technologies gaining traction, reducing cooling costs and mitigating urban heat island effects. Mosaic shingles, with their varied granule compositions, can contribute to reflective roofing solutions, aligning with these environmental goals.

Understanding Mosaic Shingles: Technical Parameters and Specifications

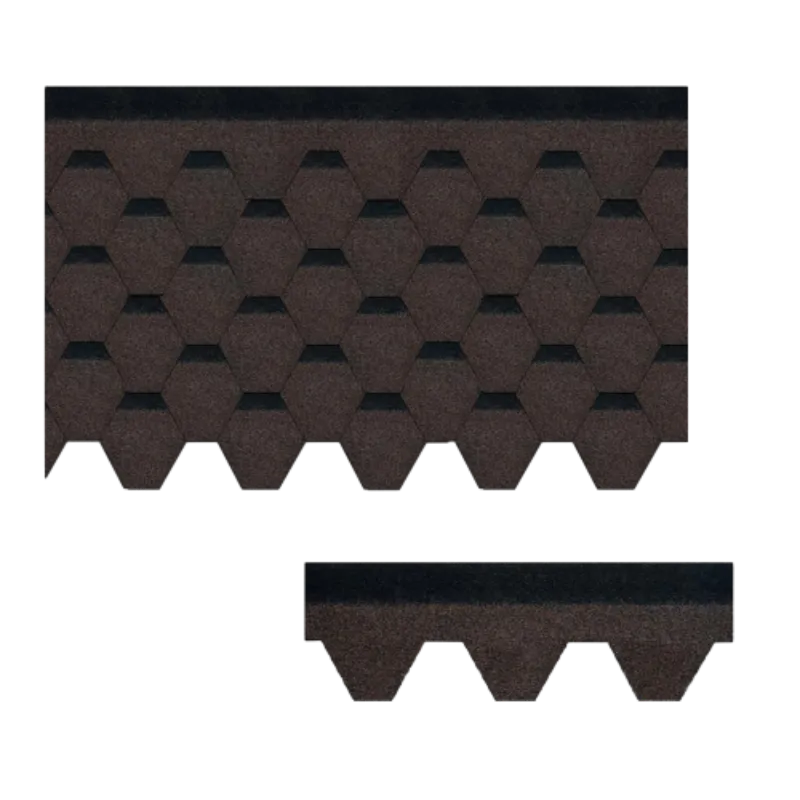

Mosaic shingles, often classified under laminated or architectural shingles due to their multi-layered construction, are designed to emulate the rich, dimensional look of natural slate or wood shakes without the associated maintenance and cost. Their unique "mosaic" appearance comes from the irregular, overlapping layers and specially blended granule colors that create a multi-tone, textured effect.

Key Technical Specifications of Mosaic Shingles

Below is a typical specification table for high-quality mosaic shingles, highlighting parameters crucial for performance and durability. It's important to note that exact specifications may vary slightly between manufacturers but generally adhere to industry standards like ASTM International.

| Parameter | Typical Specification | Standard Reference |

|---|---|---|

| Material Composition | Heavyweight fiberglass mat coated with oxidized asphalt, topped with ceramic-coated mineral granules and a self-sealing adhesive strip. | ASTM D3462 (Asphalt Shingles) |

| Layers | Multiple (typically 2-3 layers laminated together), creating a dimensional profile. | N/A (Design-specific) |

| Weight (per square) | Approx. 240-300 lbs (109-136 kg) per 100 sq ft (9.29 m²) | ASTM D3462 |

| Dimensions (per shingle) | Varies, typically 13 1/4" x 39 3/8" (337mm x 1000mm) for individual shingles, with varying exposure. | N/A (Manufacturer-specific) |

| Wind Resistance Rating | Up to 130 mph (209 km/h) with proper installation | ASTM D3161 (Class F), ASTM D7158 (Class H) |

| Fire Resistance Rating | Class A (highest rating) | ASTM E108 (UL 790) |

| Algae Resistance | Granules infused with copper to inhibit algae growth for 10-15 years. | ASTM D3462 (for granule retention) |

| Impact Resistance | Class 3 or Class 4 (for specific products) | UL 2218 |

| Solar Reflectance (SRI) | Varies by color; certain "Cool Roof" colors ≥ 0.25 (Initial SR) | ASTM C1549, ASTM E1980 |

| Warranty (Limited Lifetime) | 30 to 50 years, often with a non-prorated period (e.g., 10-15 years). | Manufacturer-specific |

The Craft Behind Durability: Manufacturing Process of Mosaic Shingles

The creation of high-quality mosaic shingles is a sophisticated process involving precision engineering and material science. Unlike simple stamped roofing materials, laminated shingles undergo a complex assembly line to achieve their multi-dimensional structure and performance attributes.

Fiberglass Mat Production

The foundation of a mosaic shingle is a strong, dimensionally stable fiberglass mat. This mat is produced by interweaving glass fibers into a thin, porous fabric. This provides the shingle with its inherent strength, tear resistance, and dimensional stability, preventing curling and warping over time. It's crucial for the shingle's overall integrity and adherence to standards like ASTM D226 for roofing felts.

Asphalt Saturation & Coating

The fiberglass mat is then continuously fed through a large vat of specialized asphalt. This asphalt is typically oxidized to enhance its weatherproofing properties, flexibility, and longevity. The mat is fully saturated with this hot asphalt, which impregnates the fibers and creates a waterproof core. A thicker coating of asphalt is then applied to both sides of the saturated mat, forming the protective layers of the shingle. This step is critical for providing the shingle's primary weather barrier and UV resistance.

Granule Application & Blending

Immediately after the asphalt coating, mineral granules are embedded into the top surface of the shingle. These granules are ceramic-coated for color stability and UV protection. For mosaic shingles, multiple colors and shapes of granules are precisely blended and applied in varying concentrations to create the desired multi-dimensional, textured, and often variegated aesthetic. Some granules may also be treated with copper to provide long-term algae resistance. A fine mineral release agent is applied to the back to prevent shingles from sticking together in the bundle.

Cutting & Lamination

After the granules are firmly embedded, the continuous asphalt-coated mat is cut into individual shingle lengths. This is where the distinct "laminated" or "architectural" aspect comes in: these individual pieces, or "shingle tabs," are then precisely overlapped and laminated (bonded with adhesive and pressure) to a base layer, creating a multi-layered, thicker profile. This lamination process is key to achieving the dimensional look and enhanced durability of mosaic shingles, distinguishing them from single-layer 3-tab shingles.

Self-Sealing Adhesive Strip Application

A thermo-activated asphaltic adhesive strip is applied to the underside of the shingle. Once installed on a roof and exposed to solar heat, this strip melts slightly and then firmly bonds to the shingle below it, creating a strong, wind-resistant seal. This "self-sealing" feature significantly enhances the shingle's ability to withstand high winds and prevents wind uplift.

Quality Control & Packaging

Throughout the entire process, rigorous quality control measures are implemented. This includes continuous monitoring of asphalt application thickness, granule embedment, shingle dimensions, and adhesive strip integrity. Shingles are tested for compliance with industry standards such as ASTM D3462 (general asphalt shingle requirements), ASTM D3161 (wind resistance), and ASTM E108 (fire resistance). Products typically have a service life ranging from 30 to 50 years, backed by robust warranties. Once approved, the finished mosaic shingles are stacked, packaged, and prepared for distribution. This stringent inspection protocol ensures consistent product quality and adherence to specified performance metrics.

Application Scenarios and Strategic Advantages of Mosaic Shingles

Mosaic shingles are highly versatile and suitable for a wide range of applications, demonstrating significant advantages over traditional roofing materials. While not typically used in heavy industrial sectors like petrochemical or metallurgy in the same way, their primary application lies in the residential and light commercial sectors where aesthetics, durability, and cost-effectiveness are paramount. For instance, in "water supply and drainage" related buildings (e.g., pump stations, treatment plants administration buildings), they offer a superior, long-lasting roofing solution.

- Residential Housing: From suburban homes to custom luxury residences, mosaic shingles provide a dramatic upgrade in curb appeal. Their varied textures and color blends can complement diverse architectural styles, from traditional to contemporary.

- Multi-Family Dwellings: Apartment complexes, condominiums, and townhouses benefit from the durable and low-maintenance nature of mosaic shingles, offering a consistent and appealing look across multiple units.

- Light Commercial Buildings: Retail centers, office parks, churches, and community centers often opt for mosaic shingles for their professional appearance and long-term performance, enhancing the property's value.

- Renovation and Re-roofing Projects: They are an ideal choice for homeowners looking to significantly upgrade their existing roof, providing enhanced protection and a fresh, modern aesthetic.

Key Advantages in Typical Application Settings:

- Enhanced Curb Appeal: The multi-dimensional design and blended colors create a rich, textured look that significantly boosts property value and aesthetic appeal. This is especially vital for residential and commercial properties aiming for a premium appearance.

- Superior Weather Protection: Engineered to withstand harsh weather, including high winds (often rated up to 130 mph), heavy rain, and hail. Their multi-layered construction provides a robust barrier against the elements, crucial for areas prone to severe weather.

- Long-Term Durability and Longevity: With service lives typically ranging from 30 to 50 years, mosaic shingles offer exceptional long-term value, reducing the frequency and cost of roof replacements.

- Energy Efficiency (Cool Roof Options): Certain lighter-colored mosaic shingles are designed with highly reflective granules that meet cool roof standards, effectively reflecting sunlight and reducing heat absorption, leading to significant energy savings on cooling costs in warmer climates.

- Algae Resistance: Many mosaic shingles incorporate copper-infused granules that inhibit the growth of blue-green algae, preventing unsightly black streaks and maintaining the roof's aesthetic integrity over time.

- Ease of Installation & Maintenance: While more substantial than 3-tab shingles, they are still relatively straightforward for experienced roofing contractors to install. Their robust construction also means lower maintenance requirements compared to other high-end roofing materials.

Deep Dive: Distinguishing Shingle Types for Informed Decisions

Understanding the nuances between different shingle types is crucial for making an informed roofing decision. The terms "3-tab," "architectural," and "laminate" shingles often cause confusion, yet they represent distinct categories in terms of construction, appearance, and performance. Mosaic shingles typically fall under the architectural/laminate category due to their advanced construction.

What is the Difference Between 3-Tab and Architectural Shingles?

This is perhaps the most common question in residential roofing. The core distinctions lie in their construction and aesthetic impact:

- 3-Tab Shingles: These are the most basic and economical asphalt shingles. They consist of a single, flat layer of asphalt and fiberglass mat with regular cutouts along the bottom edge, creating the appearance of three individual tabs per shingle strip.

- Appearance: Flat, uniform, and less dimensional. They give a very traditional, often "flat" look to the roof.

- Construction: Single layer. Lighter in weight (e.g., 210-235 lbs/square).

- Durability: Generally offer less wind resistance (e.g., 60-70 mph) and shorter warranties (e.g., 20-25 years) compared to architectural shingles. They are more prone to wind uplift and tear-off.

- Cost: Lowest upfront cost.

- Architectural Shingles (Laminated Shingles): These are multi-layered, heavier, and more robust. They are also known as "laminated" shingles because their construction involves laminating multiple layers of asphalt and fiberglass together. Mosaic shingles are a specialized type of architectural shingle.

- Appearance: Designed to mimic the look of natural wood shakes or slate, offering a rich, dimensional, and textured appearance. The varied tabs and irregular edges create depth and shadow lines.

- Construction: Two or more layers of asphalt and fiberglass laminated together. Significantly heavier (e.g., 240-400+ lbs/square).

- Durability: Offer superior wind resistance (e.g., 110-130+ mph), better impact resistance, and much longer warranties (e.g., 30 years to limited lifetime). Their thickness provides better protection against hail and general wear.

- Cost: Higher upfront cost than 3-tab, but better long-term value due to durability and extended lifespan.

What is the Difference Between 3-Tab and Laminate Shingles?

As explained above, "laminate shingles" is simply another term for "architectural shingles." They refer to the same type of multi-layered, dimensional asphalt shingle. So, the differences are identical to those between 3-tab and architectural shingles.

What is the Difference Between 3-Tab Shingles and Architectural?

This phrasing reiterates the primary comparison. In essence, 3-tab shingles are a basic, single-layer option focused on economy and simple coverage. Architectural shingles (including mosaic shingles) are a premium, multi-layered product focused on enhanced durability, superior aesthetics, and extended performance. The choice depends on budget, desired lifespan, and aesthetic preferences.

What is the Difference Between Architectural Shingles and 3-Tab?

This is simply the reverse phrasing of the above. The key takeaway is that architectural (laminate/dimensional) shingles provide a significant upgrade in terms of visual appeal, structural integrity, and long-term protection compared to their 3-tab counterparts. For a quick overview, consider the following comparison table:

| Feature | 3-Tab Shingles | Architectural/Laminate Shingles (e.g., Mosaic Shingles) | |||

|---|---|---|---|---|---|

| Layers | Single | Multiple (2-3+ laminated) | |||

| Appearance | Flat, uniform, less dimensional | Dimensional, textured, mimics wood/slate, varied patterns (like mosaic) | |||

| Weight (per square) | Lighter (approx. 210-235 lbs) | Heavier (approx. 240-450+ lbs) | |||

| Wind Resistance | Lower (60-70 mph) | Higher (110-130+ mph) | |||

| Warranty | Shorter (20-25 years) | Longer (30 years to Limited Lifetime) | |||

| Cost (Upfront) | Lower | Higher | Value (Long-term) | Lower due to shorter lifespan/replacement cycles | Higher due to extended durability, enhanced protection, and aesthetic appeal |

Selecting a Manufacturer: Ensuring Quality and Reliability

When investing in mosaic shingles, the choice of manufacturer is as critical as the product itself. Reputable manufacturers distinguish themselves through rigorous quality control, adherence to international standards, and a proven track record of customer satisfaction.

Key Criteria for Manufacturer Evaluation ( Focus)

- Certifications & Standards (Authoritativeness): Look for manufacturers whose products are certified by independent bodies such as ASTM International (e.g., ASTM D3462 for asphalt shingles, ASTM E108 for fire resistance, ASTM D3161 for wind resistance). ISO 9001 certification for quality management systems indicates a commitment to consistent product quality.

- Industry Standing & Service Years (Authoritativeness): Manufacturers with decades of experience in the roofing industry often have a deeper understanding of material science and product performance. Their longevity signifies reliability and stability.

- Product Portfolio & Innovation (Expertise): A diverse range of high-performance products, including "cool roof" technologies and advanced color blends for mosaic shingles, suggests a commitment to innovation and meeting evolving market demands.

- Warranty & Guarantees (Trustworthiness): A comprehensive, transferable, non-prorated warranty (especially for the initial years) speaks volumes about a manufacturer's confidence in their product's durability. Ensure the warranty covers both materials and workmanship (if installed by certified contractors).

- Customer Support & Technical Assistance (Trustworthiness): Access to readily available technical support, installation guides, and responsive customer service is vital for problem-solving and ensuring proper product application.

- Customer Feedback & Case Studies (Experience): Authentic testimonials, public reviews, and documented case studies of successful projects demonstrate real-world performance and customer satisfaction.

- Sustainability Practices: Manufacturers committed to environmental responsibility, through recycled content or reduced emissions in their production, align with modern sustainability goals.

Customized Solutions and Aesthetic Versatility

One of the significant advantages of mosaic shingles is their inherent design flexibility. Manufacturers offer a wide array of color palettes, ranging from subtle earth tones to vibrant multi-color blends, allowing property owners to achieve a truly customized look that complements their home's architectural style and surrounding landscape. For instance, a classic colonial home might benefit from a multi-tone gray mosaic shingle to mimic slate, while a rustic contemporary design could utilize warmer brown and red hues to emulate wood shakes.

Beyond standard color options, some manufacturers offer bespoke color blending services for large-scale or unique projects, providing unparalleled design freedom. This customization extends to the visual texture created by the varying granule application and shingle tab shapes, enabling architects and designers to achieve specific aesthetic visions.

Real-World Impact: Application Cases and Customer Feedback

Our commitment to delivering high-performance mosaic shingles is consistently validated by successful installations and positive client feedback across diverse projects.

Case Study Highlight: Suburban Residential Re-roofing

Project: A 2,500 sq ft residential home in a climate zone experiencing high winds and significant temperature fluctuations.

Challenge: The previous 3-tab asphalt roof was nearing its end-of-life, showing signs of granule loss and wind damage after only 20 years. The homeowner desired a more durable, aesthetically appealing, and energy-efficient solution without opting for expensive alternatives like metal or tile.

Solution: We recommended and installed our premium mosaic shingles in a blend of charcoal and grey tones, providing a sophisticated, dimensional look. The shingles' Class H wind resistance (ASTM D7158, rated for up to 130 mph) and Class A fire rating (ASTM E108) offered superior protection.

Outcome: Two years post-installation, the roof has withstood multiple severe storms with no reported damage. The homeowner reported a noticeable reduction in summer cooling costs, attributing it to the reflective properties of the new shingles. The enhanced curb appeal also significantly boosted the property's market value.

Case Study Highlight: Light Commercial Office Building

Project: A 10,000 sq ft, single-story office complex needing a complete roof replacement due to age and persistent leaks.

Challenge: The client required a durable, low-maintenance roofing solution that would project a professional image and offer longevity suitable for a commercial property, while also being cost-effective compared to flat roofing systems.

Solution: We specified mosaic shingles with an algae-resistant feature in a deep brown blend to complement the building's brick facade. The shingles' robust construction and 50-year limited lifetime warranty ensured long-term peace of mind for the property managers.

Outcome: The installation was completed efficiently, minimizing disruption to business operations. The new roof successfully eliminated all leaks and provided an updated, modern look for the entire complex. The algae-resistant granules have kept the roof pristine, significantly reducing maintenance needs.

Frequently Asked Questions About Mosaic Shingles

Commitment to Excellence: Delivery, Warranty, and Support

At Cool Roof Materials, we understand that investing in a new roof is a significant decision. Therefore, we are dedicated to ensuring a seamless experience from selection to installation and beyond. Our mosaic shingles are subject to stringent quality control, backed by comprehensive support services.

- Delivery Cycle: We maintain efficient logistics and inventory management to ensure timely delivery of our mosaic shingles. Standard orders are typically processed and shipped within 3-5 business days, with larger or custom orders having a clearly communicated lead time. Our distribution network is designed to minimize delays and ensure product availability.

- Quality Assurance & Warranty: Our mosaic shingles are manufactured to meet or exceed industry standards, including ASTM D3462, ASTM D3161 (wind resistance), and ASTM E108 (fire resistance). We stand behind the quality of our products with a robust Limited Lifetime Warranty, covering material defects for the lifespan of the roof, and often including a non-prorated period. Details of our warranty are transparently provided to all clients, ensuring complete peace of mind.

- Customer Support: Our dedicated customer support team is available to assist with product selection, technical inquiries, installation guidance, and any post-purchase concerns. We believe in building lasting relationships with our clients through reliable service and expert advice. You can reach our support specialists via phone, email, or our website's contact form during business hours.

References and Further Reading:

- "Global Roofing Market Size, Share & Trends Analysis Report By Product (Asphalt Shingles, Tile, Metal), By Application (Residential, Non-residential), By Region, And Segment Forecasts, 2023 - 2030." Grand View Research. Available at: https://www.grandviewresearch.com/industry-analysis/roofing-market

- "Asphalt Shingle Roofing Manual." Asphalt Roofing Manufacturers Association (ARMA). This manual provides comprehensive guidance on the design, application, and maintenance of asphalt shingle roofs. Available via ARMA's official website: https://asphaltroofing.org/resources/publications/ (requires membership or purchase for full access to certain documents).

- "Cool Roofs." U.S. Department of Energy, Energy Efficiency & Renewable Energy. Provides insights into the benefits and technologies behind energy-efficient roofing solutions. Available at: https://www.energy.gov/energysaver/cool-roofs

-

Explore Types of Roof Shingles: Durable Asphalt & More!

NewsAug.07,2025

-

Architectural Asphalt Shingles | Laminated & Durable

NewsAug.06,2025

-

Premium Stone Coated Metal Roof Tiles | Spain Tile

NewsAug.05,2025

-

Types of Roof Shingles: Durable Styles & Materials

NewsAug.04,2025

-

Different 3 Tab Shingles Types | Affordable & Durable Roofing

NewsAug.03,2025