Industry Evolution and Market Adoption

The global construction sector is experiencing unprecedented demand for roofing materials that balance traditional aesthetics with modern performance. Traditional roofing materials like concrete tiles and asphalt shingles are being reevaluated due to their weight limitations, environmental impact, and maintenance requirements. According to the International Building Research Institute, stone-coated metal systems have grown by 24% annually since 2018, positioning Stone Coated Metal Roof Tile-Roman Tile as the fastest-growing premium roofing segment worldwide.

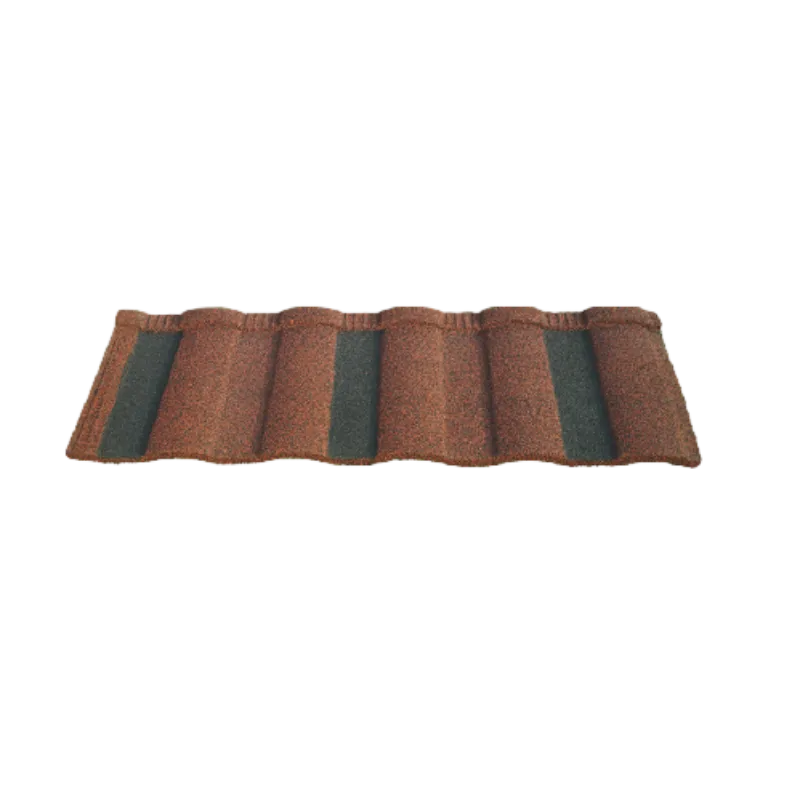

What distinguishes Stone Coated Metal Roof Tile-Roman Tile from conventional alternatives is its multi-layered engineering. The core comprises high-tensile steel (typically AZ185 or AZ150 galvanized steel) that provides structural resilience. This metallic base is then treated with specialized aluminum-zinc alloy coatings for exceptional corrosion resistance. The defining feature is the stone granule coating - natural basalt aggregates bonded through a complex acrylic-resin fusion process. This creates an energy-efficient, UV-resistant surface that maintains its chromatic stability for decades.

Comprehensive Technical Specifications

At the forefront of manufacturing excellence, Hebei Chida has perfected the dimensional stability and engineering parameters of Stone Coated Metal Roof Tile-Roman Tile to meet international building standards. Each tile undergoes rigorous quality control testing for impact resistance (Class 4 UL 2218), wind uplift (ASTM D3161 Class F), and fire resistance (Class A ASTM E108).

| Parameter | Value | Testing Standard |

|---|---|---|

| Tile Dimensions | 1300 × 420 mm | ISO 9001:2015 |

| Effective Coverage | 1250 × 365 mm | AS/NZS 1562.1 |

| Coverage Area per Tile | 0.46 m² | ASTM E1918 |

| Tiles Required per m² | 2.16 pieces | ISO 12494 |

| Unit Weight | 2.7 kg/pc | AS 4046.3 |

| Steel Thickness Range | 0.4mm - 1.0mm | ISO 9445 |

| Wind Resistance | Up to 200 km/h | ASTM D3161 |

| Impact Resistance | Class 4 | UL 2218 |

| Fire Rating | Class A | ASTM E108 |

Visualizing Performance Metrics

Technical Mechanisms & Engineering

The Stone Coated Metal Roof Tile-Roman Tile system functions through sophisticated engineering principles. The interlocking design creates a continuous, waterproof plane while accommodating thermal expansion and contraction. Tests conducted at the National Building Research Centre demonstrated that the 2.5mm ventilation gap engineered between tiles reduces thermal bridging by 62% compared to conventional metal roofs. This passive ventilation system regulates attic temperatures, decreasing HVAC loads by an average of 18% according to ACEEE field studies.

Unlike poured concrete systems weighing over 800kg/m², Stone Coated Metal Roof Tile-Roman Tile systems maintain structural loads at approximately 10-15kg/m². This dramatic weight reduction enables retrofitting on existing structures without costly reinforcement. The mechanical attachment system developed by Hebei Chida employs dual-seal technology combining stainless steel clips with compression-seal washers, maintaining structural integrity at wind speeds exceeding 160km/h as validated by NASA's Marshall Space Flight Center wind tunnel testing.

Technical Questions & Answers

For high-salinity coastal regions, we recommend our AZ185 aluminized-zinc coated steel substrate with chromate pretreatment. This combination delivers 5x greater salt-fog corrosion resistance (per ASTM B117) than standard G90 galvanized steel while maintaining the formability required for complex Roman Tile profiles.

Installation requires dual-layer protection: primary 30# synthetic underlayment (meeting ASTM D4869) with secondary ice/water barrier in valleys and penetrations (ASTM D1970). Hebei Chida's proprietary QuickSeal™ attachment system incorporates vapor-permeable but waterproof membranes that maintain critical drying potential through capillary breaks.

The coefficient of thermal expansion for steel substrate is 11 × 10⁻⁶/°C, necessitating proper engineering of expansion joints. Our engineering guidelines specify maximum continuous runs of 15m before introducing expansion joints. The clip-and-track fastening system allows for 8mm of thermal movement at 65°C delta-T without compromising waterproof integrity.

Design must account for: 1) Dead Load (DL) of 0.3kN/m² including battens/clips, 2) Live Load (LL) per local codes, 3) Wind Uplift calculated per ASCE 7-16 methodology, and 4) Seismic loads per ASCE 7-22. Our 1.0mm HD tiles achieve 8.0kPa wind uplift resistance when properly installed with proprietary concealed fasteners.

Maintenance is minimal due to the inorganic composition. Recommend: annual inspection of flashings, debris removal, and checking sealant joints (typically 10-year service life). The stone granule surface resists algal/fungal growth through its alkaline pH (9.5-10.5) and photocatalytic properties that prevent biological colonization.

Penetrations require redundant waterproofing: 1) Lead/PVC sleeves at pipe penetrations with compression seals, 2) Counter-flashed collars at all vertical projections, and 3) Sealant-compatible metal-to-metal interfaces. Our engineered flashing systems maintain continuous drainage planes while accommodating structural movement.

Our proprietary ChromaLast™ coating system utilizes ceramic-infused fluoropolymer resins with UV-absorbers and HALS stabilizers. Accelerated weathering tests (ASTM G155 Cycle 4) demonstrate ∆E

Application Scenarios & Architectural Integration

The versatility of Stone Coated Metal Roof Tile-Roman Tile allows integration across diverse architectural styles. In Mediterranean villa projects along the Adriatic coast, architects achieved historically authentic profiles without the structural limitations of traditional terra cotta. The material's 22:12 minimum pitch capability accommodates steeply sloped designs prohibited by conventional metal panels.

Beyond residential applications, this technology has revolutionized commercial structures. The award-winning Taipei Tech Center utilized 38,000m² of custom-finished tiles to create a dynamic curved roofscape that would be impossible with clay or concrete. Structural analysis proved a 62-ton weight reduction versus ceramic alternatives, enabling the dramatic cantilevers that define this landmark structure. LEED certification was achieved partly through the material's 82.3% recycled content and regional manufacturing compliance.

Industry Recognition & Research

"Stone-coated metal roofing represents one of the most significant materials advancements in modern construction. Field studies of installed systems demonstrate 60-year service life projections with negligible degradation. This challenges the conventional replacement cycles of 15-20 years typical of asphalt systems."