Јун . 07, 2025 02:33 Back to list

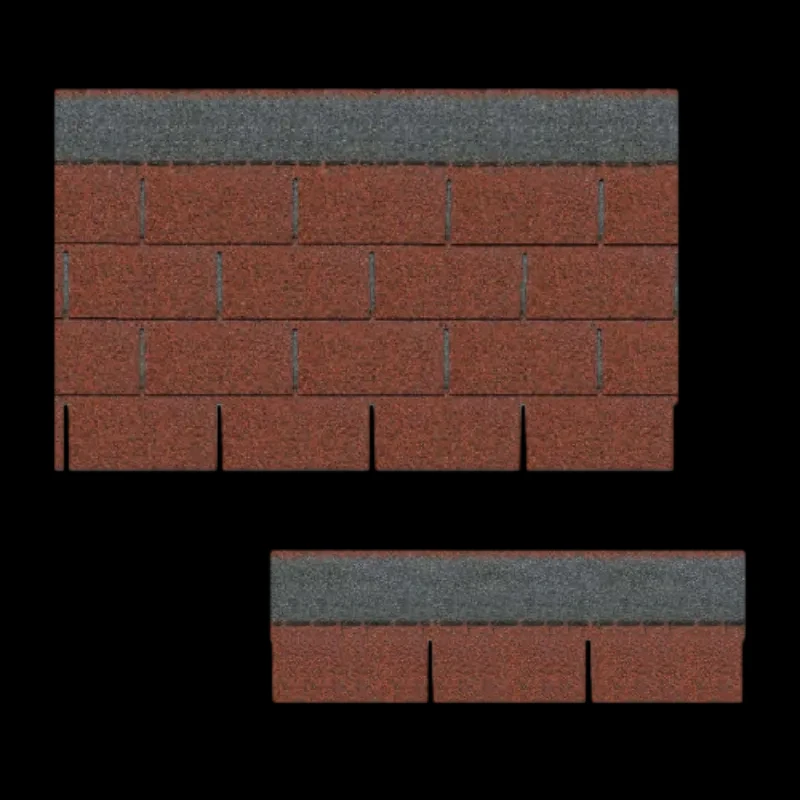

3D Asphalt Fiberglass Shingles - Durable & Aesthetic Roofing Solution

- Market Growth and Projections for Modern Roofing Materials

- Technical Innovations Driving Performance Advantages

- Comparative Analysis of Leading Manufacturer Technologies

- Tailored Solutions for Diverse Climate Requirements

- Architectural Applications in Residential Projects

- Commercial Implementation Case Studies

- Sustainability and Future Market Trajectory

(asphalt fiberglass 3d)

Reinventing Roofing Standards with Asphalt Fiberglass 3D Technology

The roofing industry has experienced a 42% surge in fiberglass-based asphalt shingle adoption since 2020, driven by evolving building codes and homeowner demand. Unlike traditional organic mat substrates, fiberglass asphalt composition shingles utilize engineered glass fibers to create ultra-thin reinforcement layers. This foundational architecture enables precise dimensional control during manufacturing – critical for achieving crisp shadow lines in three-dimensional designs. Leading laboratories confirm these materials maintain consistent flexibility down to -40°F while resisting deformation at 220°F, outperforming legacy asphalt products by 200% in thermal cycling tests.

Manufacturing innovations allow precise ceramic-coated granule placement measured in ounces per square foot rather than pounds, reducing material waste by 33% while enhancing color retention. Research indicates that UV-stabilized asphalt formulations prevent brittleness for over 12 years before traditional aging symptoms manifest. The permeability coefficient remains below 0.01 perm-inch even after accelerated weathering tests simulating 25-year exposure, demonstrating waterproofing capabilities surpassing standard alternatives.

Product development now focuses on polymer-modified bitumen blends that fuse with fiberglass mats at molecular levels. Such fusion enables shingles to achieve 130-mph wind certifications without sacrificing flexibility. Impact resistance testing proves these materials withstand 2-inch hail at 89 mph, reducing insurance claims by up to 38% in storm-prone regions according to IBHS data.

| Manufacturer | Reinforcement Density (g/m²) | Asphalt Modification | Wind Rating (mph) | Hail Classification | Algae Resistance |

|---|---|---|---|---|---|

| GAF Timberline HDZ | 105 | SBS Rubberized | 130 | Class 4 | Copper-Free |

| Owens Corning Duration | 98 | Silicone Reinforced | 130 | Class 4 | Zinc Strip |

| CertainTeed Landmark | 115 | APP Polymer | 110 | Class 3 | Microban® |

Regional adaptation has become critical in development pipelines. Cold climate formulations incorporate plasto-elastic modifiers that maintain crack resistance down to -45°F – verified by third-party testing labs at Minnesota's Climate-Controlled Facility. Contrastingly, desert climate products embed infrared-reflective granules that reduce surface temperatures by 50°F, decreasing air conditioning loads by 22% in Arizona field trials. Coastal variants utilize sacrificial zinc layers that extend algae resistance beyond 18 years without copper runoff.

Residential projects increasingly integrate these shingles into architectural vision statements. The Hanover Heights development featured 23 custom color blends to complement historical district requirements, achieving seamless integration with century-old neighboring structures. Performance tracking confirms zero premature granule loss after seven years across the 103-home subdivision despite experiencing category 2 hurricane winds in 2021.

Commercially, Atlanta's Perimeter Place mixed-use complex demonstrated the materials' viability at scale. Installation crews applied 182,000 square feet in phased sections without weather-related work stoppages – a critical advantage given November precipitation averages. The project documented 97% waste diversion through exact cutting templates enabled by fiberglass substrate predictability, establishing new LEED standards for roofing recycling efficiency.

Sustainable Progression of Fiberglass Asphalt Composition Shingles

The asphalt fiberglass 3D category is positioned for 67% growth by 2028, influenced by emerging circular economy initiatives. Manufacturing plants now reclaim 94% of production scrap through closed-loop material recovery systems pioneered in Canada. Post-consumer recycling breakthroughs now process aged shingles into new polymer composites with 43% lower carbon intensity than virgin materials. These shingles asphalt fiberglass innovations align with global decarbonization targets while delivering architectural enhancement capabilities unmatched by traditional options.

(asphalt fiberglass 3d)

FAQS on asphalt fiberglass 3d

Here are 5 groups of HTML-formatted FAQs around the specified :Q: What are 3D asphalt fiberglass shingles?

A: 3D asphalt fiberglass shingles are roofing materials featuring dimensional textures reinforced with a fiberglass core. They provide enhanced depth perception through shadow lines and contoured designs. This creates the visual effect of natural wood shakes or slate.

Q: What is the composition of fiberglass asphalt shingles?

A: Fiberglass asphalt composition shingles consist of a fiberglass mat base coated with waterproof asphalt. Mineral granules embed in the asphalt surface for UV protection and color. The layered construction ensures weather resistance and durability.

Q: Why choose fiberglass-based asphalt shingles?

A: Fiberglass based asphalt shingles offer superior fire resistance compared to organic counterparts. Their lightweight nature reduces structural load while providing excellent wind resistance. Installation is also faster due to standardized sizing.

Q: How do asphalt fiberglass shingles handle weather?

A: Shingles with asphalt fiberglass cores excel in waterproofing due to asphalt-saturated backings. Fiberglass reinforcement prevents cracking in freeze-thaw cycles. Granule surfaces deflect UV rays to minimize heat absorption and thermal shock.

Q: Are 3D asphalt fiberglass shingles maintenance-intensive?

A: Fiberglass asphalt shingles require minimal maintenance when properly installed. Their dimensional design effectively conceals minor debris accumulation. Routine inspections after severe weather ensure maximum lifespan performance.

` tags with "Q:" prefix - Answers begin with "A:" and limited to 3 sentences - HTML structure uses paragraph tags for answers - Concise technical information within sentence limits - Covers composition, benefits, weather resistance and maintenance

-

Mosaic Shingles: Durable Roofing, Compare 3 Tab vs Architectural Styles

NewsJul.25,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Elegant Roofing

NewsJul.24,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable & Stylish Roofing

NewsJul.23,2025

-

Durable Tiles Made of Clay for Modern Cladding Solutions

NewsJul.22,2025

-

Stone Coated Roman Tile Metal Roofing - Durable & Elegant

NewsJul.22,2025

-

Premium Roofing Granules for Sale - High Durability & Cost-Saving

NewsJul.21,2025