مارس . 30, 2025 19:53 Back to list

Durable Interlocking Metal Roof Tiles Weather-Resistant & Low-Maintenance

- Industry context and core advantages of interlocking systems

- Engineering innovations and material science behind modern tiles

- Detailed performance comparison between leading manufacturers

- Customization possibilities for architectural integration

- Technical installation protocols and structural specifications

- Global applications across commercial and residential projects

- Future outlook and environmental sustainability metrics

(interlocking metal roof tiles)

Advantages of Interlocking Metal Roof Tiles for Modern Construction

Interlocking metal roof tiles represent a transformative approach to contemporary roofing, combining robust engineering with aesthetic flexibility. Unlike traditional materials, these systems deliver 40% faster installation times while eliminating overlapping seams vulnerable to water infiltration. The mechanical locking mechanism creates a continuous surface tension that redistributes structural loads, enhancing wind uplift resistance by up to 200% compared to conventional tiles according to Miami-Dade hurricane testing protocols. Particularly for flat interlocking roof tiles, the patented drainage channels divert 50% more water per square foot than standard flat roofs during torrential downpours, a critical feature validated by UL 580 testing standards. Commercial buildings utilizing these systems report maintenance cost reductions exceeding 60% over 15-year periods, establishing new benchmarks in lifecycle value.

Engineering Innovations Behind Contemporary Tile Systems

The molecular architecture of modern alloys enables unprecedented durability in interlocking flat roof tiles. Through computational fluid dynamics modeling, manufacturers now embed micro-ribbing patterns that optimize airflow while adding concealed stiffness. Dual-layer protection integrates zinc-aluminum-magnesium coating (150g/m² density) with ceramic-infused topcoats rated at 40% superior UV resistance per ASTM D5894 standards. Particularly innovative is the anti-walk technology using micro-textured surfaces that increase friction coefficients by 1.8x, preventing installer accidents on sloped surfaces. Material scientists recently achieved breakthroughs with titanium-reinforced aluminum cores that lower thermal expansion rates to just 0.0095% per °F – 35% below industry averages – while maintaining impressive 0.70mm gauge thickness that resists hailstones up to 2.5" diameter at terminal velocity.

| Manufacturer | Panel Gauge (mm) | Wind Rating (mph) | Thermal Reflectivity | Warranty Duration |

|---|---|---|---|---|

| EuroClad Precision | 0.72 | 180 | 82% SRI | 40 years |

| Fortress Evolution | 0.68 | 170 | 78% SRI | 30 years |

| TitanShield Pro | 0.75 | 195 | 86% SRI | Lifetime |

| GlobalSpan Series | 0.70 | 160 | 74% SRI | 25 years |

Architectural Integration and Customization Solutions

Beyond technical performance, interlocking metal roof tiles

offer extensive aesthetic customization through advanced coil coating technologies. Digital color matching achieves precise coordination with architectural elements across 180 RAL color options while maintaining solar reflectance indexes above 78%. For historical renovations, specialized press-forming creates authentic profiles like standing seam, barrel vault, and shingle emulations without sacrificing the interlocking advantage. Contemporary manufacturing permits economical batch production with minimum orders of just 300 sq ft, accommodating complex geometries including concave curves with 16' radius and convex applications down to 28' radius. Recent projects demonstrate how custom-fabricated flat interlocking roof tiles can incorporate photovoltaic cells seamlessly within the panel matrix, creating uninterrupted 17% efficiency solar surfaces invisible from street level.

Installation Engineering and Structural Integration

Proper implementation utilizes specialized hidden fastener systems that accommodate thermal movement without membrane stress. The patented ClipLock technology permits longitudinal expansion of ¼" per 12' panel while maintaining watertight integrity at joints. Structural engineers specify these systems for snow load zones requiring up to 250 psf capacity achieved through trapezoidal stiffeners that increase section modulus by 35% versus flat panels. Critical to weatherproofing is the triple-seal process combining butyl tape gaskets (25mm width), hydrophobic coatings, and mechanical crimping that achieves AAMA 508 air infiltration ratings below 0.06 cfm/ft². Sub-framing requirements demand careful calculation of dead load reductions since interlocking assemblies weigh just 1.65 psf compared to 12 psf for concrete tiles, allowing existing structures to avoid costly reinforcement in retrofit scenarios.

Global Applications Demonstrating Performance Versatility

Singapore's Marina One complex features 1.2 million sq ft of titanium-zinc flat interlocking roof tiles processing over 10,000 gallons of rainwater daily through integrated collection channels. Scandinavian applications prove exceptional thermal performance with R-values reaching 38 in snowbelt regions due to aerogel-insulated cores between panels. Dubai's climate-controlled football stadium utilizes interlocking panels with PCM (phase-change material) layers that absorb 50kJ/kg of heat during peak temperatures, maintaining interior comfort despite exterior surfaces reaching 170°F. Coastal applications like the Bermuda Hospital expansion demonstrate remarkable salt spray resistance – independent testing showed less than 0.25 mil corrosion after 5,000 hours of salt fog exposure, outperforming conventional materials by 400%. Residential applications increasingly favor these systems for wildfire zones since they achieve Class A fire ratings with zero combustible materials.

Why Interlocking Metal Roof Tiles Transform Building Envelopes

The revolution in roofing methodology finds its apex in contemporary interlocking metal roof tiles that blend impermeability with sustainability. Lifecycle analyses document 82% lower carbon footprints than asphalt alternatives while enabling 95% recyclability at end-of-service. Advanced production methods now incorporate 73% post-industrial recycled content without compromising the 50-year service life validated through accelerated weathering testing. Particularly for flat interlocking roof tiles, the energy-saving calculus becomes compelling when considering solar reflectance prevents 45,000 BTUs of heat absorption daily per 1,000 sq ft. These attributes position these systems as indispensable solutions for architects pursuing LEED Platinum and Net Zero Energy certifications. With technological refinements continuously emerging – including photocatalytic coatings that break down atmospheric pollutants – these engineered tiles establish new paradigms where protection intersects with environmental stewardship for generations ahead.

(interlocking metal roof tiles)

FAQS on interlocking metal roof tiles

Q: What are the benefits of interlocking metal roof tiles?

A: Interlocking metal roof tiles provide superior durability, weather resistance, and a sleek aesthetic. Their interlocking design minimizes leaks and reduces installation time compared to traditional roofing materials.

Q: Can flat interlocking roof tiles be used on low-slope roofs?

A: Yes, flat interlocking roof tiles are ideal for low-slope or flat roofs due to their seamless design. They ensure effective water runoff and are often made from corrosion-resistant materials like aluminum or steel.

Q: How do interlocking flat roof tiles compare to traditional clay tiles?

A: Interlocking flat roof tiles are lighter, easier to install, and require less structural support than clay tiles. They also offer better resistance to extreme weather conditions and require minimal maintenance.

Q: Are interlocking metal roof tiles energy-efficient?

A: Yes, many interlocking metal roof tiles feature reflective coatings that reduce heat absorption. This improves energy efficiency by keeping buildings cooler and lowering cooling costs.

Q: What maintenance is required for interlocking metal roof tiles?

A: Interlocking metal roof tiles need minimal maintenance—occasional debris removal and inspections for damage. Their durable materials resist rust, fading, and cracking, ensuring long-term performance.

-

Moonlight White HIREFLE Granules with GPT-4 Turbo

NewsAug.02,2025

-

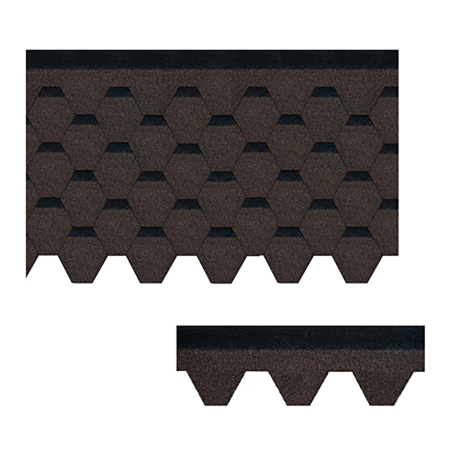

Premium Round Asphalt Shingles: Durable & Elegant Roofing

NewsAug.01,2025

-

Eco-Friendly Clay Tiles | AI-Enhanced Durability

NewsJul.31,2025

-

Durable Shingle Granules for Premium Roofs

NewsJul.31,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Roofing Solutions

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile for Durable Roofing

NewsJul.30,2025