ಆಗಸ್ಟ್ . 21, 2025 20:20 Back to list

Mosaic Shingles: 3-Tab vs. Architectural Differences Guide

Unveiling Mosaic Shingles: A Paradigm Shift in Roofing Aesthetics and Performance for B2B Applications

In the dynamic landscape of modern construction and architectural design, roofing materials are no longer merely functional components; they are integral elements contributing to a structure's aesthetic appeal, energy efficiency, and long-term resilience. Among the innovative solutions emerging, mosaic shingles represent a significant advancement, offering a distinctive blend of visual sophistication and robust performance. These specialized roofing products are engineered to provide unparalleled design flexibility, allowing architects and developers to achieve unique, high-impact facades that differentiate their projects.

The global roofing market is currently experiencing a robust growth trajectory, driven by increasing construction activities, growing demand for sustainable building materials, and the need for enhanced weather resistance in the face of climate change. Within this expansive market, there's a discernible trend towards premium, design-centric roofing solutions that offer superior longevity and curb appeal. While traditional roofing materials like three-tab and architectural shingles have long dominated the residential and light commercial sectors, the rise of specialized products like mosaic shingles addresses a niche but growing demand for truly unique and high-performance options. This segment is particularly appealing to B2B stakeholders, including luxury home builders, commercial property developers, and institutional project managers, who seek to deliver projects that stand out in a competitive market while ensuring optimal structural integrity and energy efficiency. The unique patterning and layering inherent in mosaic shingles provide a depth and texture that is distinct from conventional offerings, making them a preferred choice for landmark projects.

The Advanced Craftsmanship of Mosaic Shingles: A Deep Dive into Manufacturing Excellence

The manufacturing of mosaic shingles is a sophisticated process that combines advanced material science with precision engineering to produce a product that is both aesthetically compelling and structurally resilient. Unlike conventional shingles, the production of mosaic shingles involves meticulous layering and granulation techniques to achieve their characteristic patterned appearance and enhanced protective qualities. The process begins with carefully selected raw materials, each contributing to the final product's durability and performance profile.

Core Materials and Their Role:

- Fiberglass Mat: At the heart of every mosaic shingle lies a high-strength, non-woven fiberglass mat. This mat serves as the foundational reinforcement, providing dimensional stability and resistance to tearing and buckling. Its lightweight yet robust nature ensures that the shingles can withstand environmental stresses without excessive structural load on the roof.

- Asphalt Blend: The fiberglass mat is impregnated with a specially formulated asphalt blend. This asphalt is oxidized and often modified with polymers to enhance its waterproofing capabilities, flexibility, and resistance to UV degradation, thermal cycling, and brittleness in cold temperatures. The quality and composition of the asphalt are critical to the shingle's long-term performance and sealant properties.

- Mineral Granules: The distinctive aesthetic of mosaic shingles is largely attributed to the ceramic-coated mineral granules applied to the asphalt surface. These granules serve multiple vital functions:

- UV Protection: They shield the asphalt from harmful ultraviolet rays, which can cause premature aging and deterioration.

- Aesthetics: Available in a wide spectrum of colors, these granules are strategically blended and applied in complex patterns to create the 'mosaic' effect, offering unparalleled visual depth and texture.

- Fire Resistance: The ceramic coating enhances the shingle's fire resistance.

- Algae Resistance: Many modern granules incorporate copper or zinc particles, providing long-term protection against unsightly algae growth, particularly in humid climates.

- Release Film: A thin, finely granulated release film is applied to the back of the shingle to prevent sticking during packaging and shipping. This ensures easy separation during installation.

The Manufacturing Process: Precision and Innovation

The manufacturing process for mosaic shingles involves several meticulously controlled stages, designed to ensure consistent quality and performance:

- Mat Saturation: The fiberglass mat is unrolled and fed into a coater, where it is thoroughly saturated with the hot asphalt blend. This impregnation ensures that the mat is fully waterproofed and bonded to the asphalt.

- Granule Application: This is a critical stage for mosaic shingles. Unlike single-layer granule application, specialized machinery precisely applies multiple colors and sizes of mineral granules in a predetermined, complex pattern. This layering creates the unique dimensional and 'mosaic' aesthetic. Advanced systems might employ digital pattern programming to ensure consistency across batches.

- Lamination and Bonding: For multi-layered or 'laminated' mosaic shingles, additional layers of asphalt-coated mats are bonded together, often using a thermal or adhesive process. This lamination significantly enhances the shingle's thickness, rigidity, and overall durability, contributing to its superior performance characteristics.

- Cooling and Curing: The shingle material is then cooled to solidify the asphalt and ensure proper adhesion of the granules. Controlled cooling prevents warping and ensures the shingle maintains its structural integrity.

- Cutting and Packaging: The continuous shingle material is cut into individual shingles or pre-configured strips using high-precision cutting equipment. Integrated sealant strips are applied to the underside of the shingle to facilitate bonding to adjacent shingles during installation. Finally, the shingles are stacked and packaged for distribution.

Rigorous Testing and Quality Assurance: Adherence to Global Standards

To ensure the highest levels of quality and performance, mosaic shingles undergo stringent testing at every stage of their production. Manufacturers adhere to a comprehensive suite of international and national standards, providing assurance of product reliability and compliance. Key standards include:

- ASTM D3462 (Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules): This fundamental standard covers the minimum requirements for asphalt shingles, including material composition, dimensions, and physical properties.

- ASTM D3161 (Standard Test Method for Wind Resistance of Asphalt Shingles (Fan Induced Method)): Crucial for ensuring shingles can withstand high wind forces, this test simulates wind conditions to evaluate the shingle's ability to remain adhered to the roof deck.

- UL 2218 (Standard for Impact Resistance of Prepared Roof Covering Materials): This test classifies shingles based on their resistance to impact from falling objects (simulating hail), with Class 4 being the highest rating. Many premium mosaic shingles aim for or achieve higher impact resistance ratings.

- UL 790 (Standard Test Method for Fire Resistance of Roof Covering Materials): Determines the shingle's resistance to external fire exposure, classifying them with A, B, or C ratings, with Class A being the most fire-resistant.

- CSA A123.5 (Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules): A Canadian standard similar to ASTM D3462, ensuring compliance for products sold in North American markets.

- ISO 9001 (Quality Management Systems): While not product-specific, ISO 9001 certification indicates a manufacturer's commitment to consistent quality management processes across all operations, from raw material procurement to finished product inspection.

Service Life and Applicable Industries:

Thanks to advanced materials and rigorous manufacturing, quality mosaic shingles offer an exceptional service life, typically ranging from 30 to 50 years, often accompanied by strong limited lifetime warranties. Their superior durability and aesthetic appeal make them suitable for a diverse range of applications, extending beyond typical residential roofing:

- High-End Residential Construction: For luxury homes and custom builds where architectural distinctiveness and long-term value are paramount.

- Commercial and Public Buildings: Applicable to schools, government buildings, community centers, or retail spaces where a premium, durable, and aesthetically pleasing roof is desired to enhance corporate image and property value.

- Hospitality Sector: Hotels, resorts, and vacation properties utilize mosaic shingles to create inviting and memorable exteriors that convey quality and sophistication.

- Specialized Architectural Projects: Any project requiring a unique roof design or a specific visual effect benefits from the customization potential of mosaic shingles.

- Renovation and Restoration: Ideal for upgrading existing structures, providing a modern aesthetic while improving weather resistance and energy performance.

Advantages in Typical Application Scenarios:

- Enhanced Curb Appeal and Property Value: The striking visual patterns and dimensional texture of mosaic shingles significantly boost a property's aesthetic appeal, leading to increased market value. This is particularly crucial for real estate developers and property managers focused on maximizing asset returns.

- Superior Weather Resistance: With multiple layers and advanced asphalt formulations, these shingles offer exceptional resistance to high winds, hail impact, and heavy rainfall. This reduces the risk of storm damage and associated repair costs, providing peace of mind for building owners and insurance providers.

- UV and Algae Protection: The high-quality ceramic granules provide superior protection against harmful UV radiation, which extends the asphalt's lifespan. Integrated algae-resistant granules maintain the roof's pristine appearance over decades, minimizing maintenance efforts and costs for facility managers.

- Potential for Energy Efficiency: Certain lighter-colored or specially formulated mosaic shingles can be designed with "cool roof" properties. These materials reflect more sunlight and absorb less heat, reducing attic temperatures and subsequently lowering cooling costs for the building, a significant advantage for large commercial and industrial complexes concerned with operational expenditures.

- Durability and Longevity: The robust construction and adherence to rigorous testing standards ensure that mosaic shingles provide a long-lasting roofing solution, reducing the frequency and cost of roof replacement over the building's lifecycle.

Technical Specifications and Performance Metrics of Mosaic Shingles

Understanding the technical specifications of mosaic shingles is crucial for architects, engineers, and purchasing managers to make informed decisions. These parameters quantify the product's performance, durability, and suitability for specific environmental conditions and project requirements. Below is a detailed table outlining typical parameters for high-quality mosaic shingles, followed by an explanation of their significance.

Key Technical Parameters for Mosaic Shingles:

| Parameter | Typical Specification (Metric/Imperial) | Significance for B2B Stakeholders |

|---|---|---|

| Material Composition | Fiberglass mat, oxidized asphalt, ceramic-coated mineral granules (multi-color blend), release film. | Ensures dimensional stability, waterproofing, UV protection, fire resistance, and distinct aesthetic. Core for long-term performance. |

| Thickness (overall) | 5.5 mm - 7.0 mm (0.22 - 0.28 inches) | Indicates robustness and dimensional stability. Thicker shingles often correlate with higher impact resistance and a more pronounced aesthetic. |

| Weight per Square (100 sq ft) | 300 - 450 lbs (136 - 204 kg) | Reflects material density and durability. Higher weight often means more asphalt and granules, contributing to better wind and impact resistance. Affects structural load calculations. |

| Wind Resistance Rating | ASTM D3161 Class F (110 mph / 177 km/h) or ASTM D7158 Class H (150 mph / 241 km/h) | Crucial for projects in high-wind zones. Higher ratings reduce risk of shingle blow-off, minimizing repair costs and ensuring structural integrity. |

| Fire Resistance Rating | UL 790 Class A | Highest fire rating, essential for safety compliance in commercial and residential buildings. Reduces fire spread risk. |

| Impact Resistance Rating | UL 2218 Class 3 or Class 4 | Indicates ability to withstand hail damage. Class 4 offers superior protection, leading to reduced insurance premiums and lower long-term maintenance costs in hail-prone regions. |

| Algae Resistance Warranty | 10-20 years (depending on manufacturer and granule type) | Prevents unsightly black streaks caused by algae, preserving aesthetic appeal and reducing cleaning requirements, important for property managers. |

| Limited Lifetime Warranty | 50 years (pro-rated) for residential applications; 20-30 years for commercial applications | A strong warranty signifies manufacturer confidence and provides long-term protection for the investment, crucial for budgeting and risk management. |

| Cool Roof Performance (SRI) | Solar Reflectance Index (SRI) > 29 (for specific colors/products) | Contributes to energy efficiency, potentially reducing HVAC loads and meeting green building certifications (e.g., LEED, Title 24). Important for sustainable construction. |

These specifications are not merely numbers; they represent the engineering integrity and expected performance of the roofing system. For B2B decision-makers, evaluating these parameters is essential for ensuring the chosen material aligns with project budgets, building codes, long-term maintenance projections, and desired aesthetic outcomes. The robust nature of mosaic shingles, reflected in these specifications, positions them as a premium choice for discerning projects.

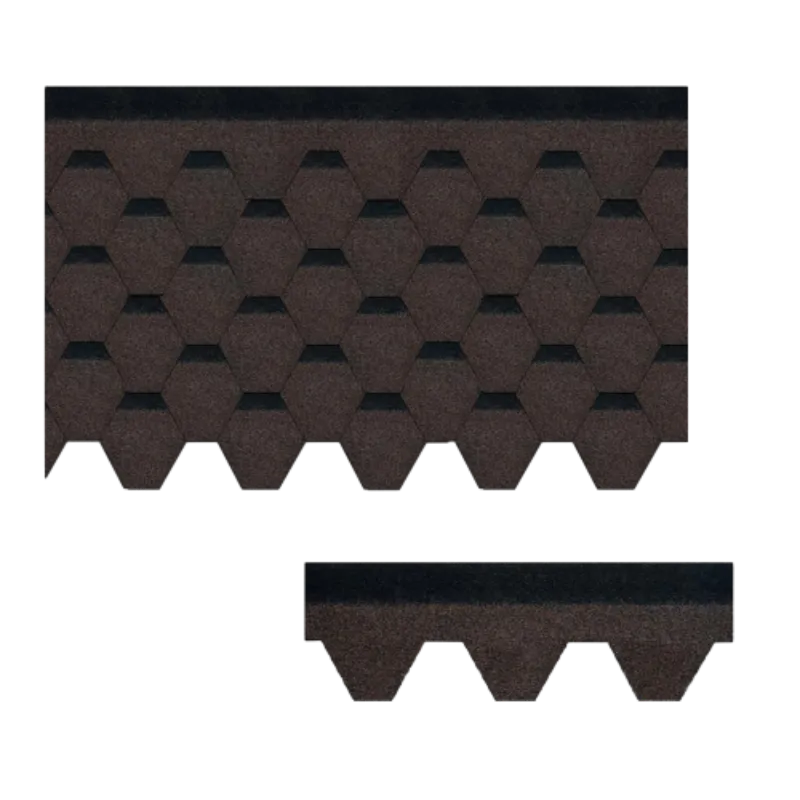

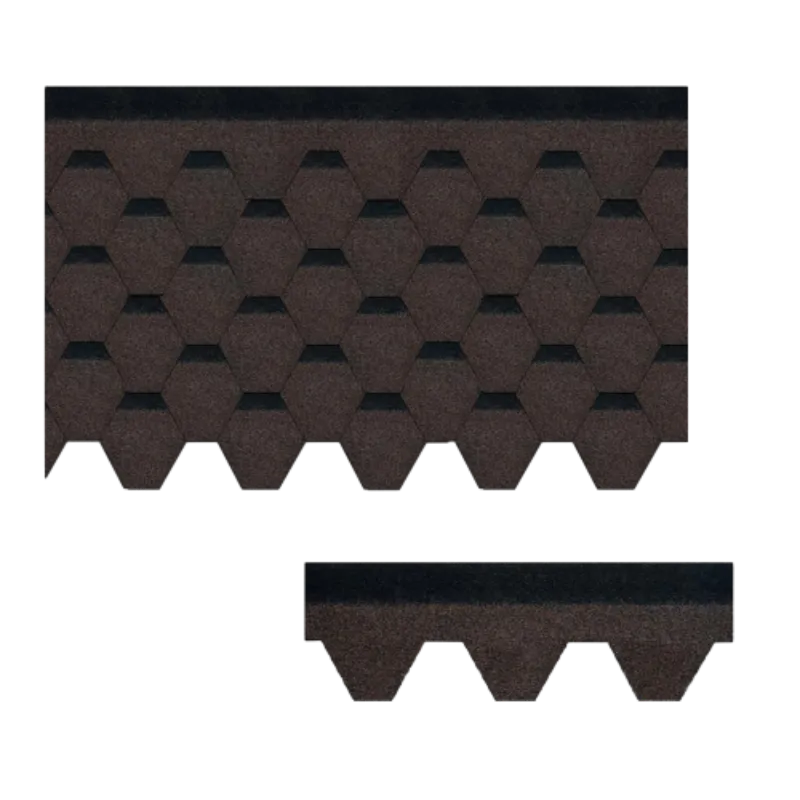

Image: A close-up view showcasing the intricate multi-layered texture and varied color granules of high-performance mosaic shingles.

Differentiating Roofing Solutions: Mosaic Shingles vs. Traditional Alternatives

When selecting a roofing material, B2B professionals face a myriad of choices, each with its own set of characteristics, advantages, and limitations. While mosaic shingles offer a distinct value proposition, it's crucial to understand how they compare to more traditional asphalt shingle types, specifically three-tab (3-tab) and architectural (laminate) shingles. This comparison will directly address the common questions: what is the difference between 3 tab and architectural shingles, what is the difference between 3 tab and laminate shingles, what is the difference between 3 tab shingles and architectural, and what is the difference between architectural shingles and 3 tab, while positioning mosaic shingles within this spectrum.

Comprehensive Comparison Table: 3-Tab, Architectural, and Mosaic Shingles

| Feature | 3-Tab Shingles | Architectural (Laminate) Shingles | Mosaic Shingles |

|---|---|---|---|

| Aesthetic Appeal | Flat, uniform appearance; classic, basic look. | Dimensional, textured look; simulates wood shakes or slate; varied shadow lines. | Highly distinctive, intricate patterns; multi-color granule blends create unique visual depth and artistic appeal; premium aesthetic. |

| Construction | Single-layer asphalt shingle with cut-outs to create three tabs. | Multi-layer (laminated) construction, often two layers bonded together. | Advanced multi-layer (laminated) construction with specialized granule application for patterned designs. |

| Thickness/Weight | Thinnest and lightest (approx. 200-240 lbs/square). | Thicker and heavier than 3-tab (approx. 250-400 lbs/square). | Thickest and heaviest (approx. 300-450 lbs/square), indicative of robust composition. |

| Durability/Lifespan | Generally 20-25 years; susceptible to wind uplift. | 30-50 years; better wind and impact resistance due to lamination. | 50+ years; superior wind, impact, and UV resistance; enhanced longevity due to advanced materials and construction. |

| Wind Resistance | Typically 60-80 mph. | Typically 110-130 mph (Class F). | Typically 110-150 mph (Class F to H), offering excellent protection. |

| Cost (Material) | Lowest initial cost. | Mid-range; significantly higher than 3-tab, but lower than premium options. | Premium cost; highest initial investment due to specialized design and enhanced performance. |

| Installation Complexity | Simplest and fastest to install. | Similar to 3-tab but slightly more complex due to random tab alignment. | May require more careful alignment to ensure pattern continuity, but generally similar to architectural. |

| Application Suitability | Budget-driven projects, temporary structures, rental properties. | Standard residential, light commercial, homeowners seeking enhanced curb appeal and durability. | High-end residential, luxury commercial, custom architectural projects, properties requiring unique visual impact and superior long-term performance. |

Key Distinctions and Value Propositions:

The fundamental difference among these shingle types lies in their construction and resulting aesthetic and performance attributes:

- 3-Tab Shingles: These are the most basic and economical. They are characterized by their single-layer construction and uniform cut-outs that create the illusion of three separate tabs when installed. Their flat appearance offers little dimensional depth, and their lighter weight generally translates to lower wind resistance and a shorter lifespan (typically 20-25 years). They serve as a cost-effective solution but lack the advanced features and aesthetic sophistication of their counterparts. This addresses the core of what is the difference between 3 tab and architectural shingles regarding their basic structure and flat look.

- Architectural (Laminate) Shingles: Also known as laminate shingles, these represent a significant upgrade from 3-tab. They are constructed with multiple layers of asphalt and fiberglass mat bonded together, creating a thicker, more robust, and dimensional product. This multi-layered design provides a varied, textured appearance that mimics natural materials like wood shakes or slate, offering enhanced curb appeal. The increased mass and bonding improve their wind resistance (often up to 130 mph) and lifespan (typically 30-50 years). The terms 'architectural' and 'laminate' are often used interchangeably, directly answering what is the difference between 3 tab and laminate shingles and what is the difference between 3 tab shingles and architectural by highlighting the layered construction and enhanced aesthetics.

- Mosaic Shingles: Building upon the foundation of architectural shingle technology, mosaic shingles elevate both aesthetics and performance to a premium level. While sharing the laminated construction of architectural shingles, they distinguish themselves through specialized granule application techniques that create intricate, deliberate patterns and multi-color blends. This results in a truly unique, artistic, and highly dimensional roof surface that cannot be replicated by standard architectural shingles. Furthermore, mosaic shingles often incorporate higher-grade materials and more advanced manufacturing processes, leading to superior impact resistance (often Class 4 UL 2218), enhanced wind ratings, and extended warranties. Their primary value lies in their ability to deliver unparalleled visual impact and long-term durability, making them ideal for projects where aesthetics and performance are paramount. This comparison directly addresses what is the difference between architectural shingles and 3 tab and extends it to the distinct advantages of mosaic options.

For B2B entities, the choice among these shingle types often boils down to balancing budget constraints with performance requirements and desired aesthetic outcomes. While 3-tab shingles offer the lowest initial cost, their shorter lifespan and lower resistance to elements may lead to higher long-term maintenance and replacement expenses. Architectural shingles provide a strong middle-ground, delivering a good balance of cost, aesthetics, and durability. However, for projects that demand a signature look, superior protection, and a truly long-term investment, mosaic shingles stand out as the definitive premium solution, offering a unique blend of artistry and engineering excellence.

Application Scenarios and Exemplary Case Studies

The unique combination of aesthetic versatility and robust performance positions mosaic shingles as a premier choice across a variety of demanding B2B application scenarios. Their ability to deliver distinct visual appeal coupled with exceptional durability makes them highly sought after in projects where curb appeal, longevity, and low maintenance are critical drivers for property value and tenant satisfaction.

Key Application Scenarios:

- Luxury Residential Estates and Gated Communities: For high-end homes, custom builds, and exclusive residential developments, mosaic shingles are chosen to create a sophisticated and individualized look that enhances property value. Their dimensional texture and varied color patterns provide an architectural statement, setting properties apart in a competitive luxury market. Developers leverage the unique appeal of mosaic shingles to attract discerning buyers looking for distinctive design and premium materials.

- Boutique Commercial Properties and Hospitality Venues: Hotels, resorts, high-end retail spaces, and specialized commercial buildings often utilize mosaic shingles to project an image of quality and distinctiveness. The roof becomes an integral part of the brand identity, contributing to the overall guest or customer experience. For instance, a boutique hotel seeking a unique, artisanal aesthetic might select mosaic shingles to complement its design narrative, ensuring the property stands out visually and operationally for decades.

- Institutional and Public Buildings: Schools, libraries, community centers, and government facilities benefit from the long-term durability and low maintenance of mosaic shingles. While aesthetics are important, the emphasis here is often on robust performance against harsh weather, fire resistance, and a long service life to minimize future public expenditure on roofing repairs and replacements. The sophisticated appearance can also contribute positively to public perception of the facility.

- Architectural Renovation and Restoration Projects: For projects involving the revitalization of older buildings or the upgrading of existing structures, mosaic shingles can provide a modern yet timeless roofing solution. They can replicate certain historical roofing textures while offering vastly superior contemporary performance metrics (e.g., wind resistance, hail impact). This allows architects to maintain design integrity while significantly improving the building's resilience and energy efficiency.

- Multi-Family Developments (Condos, Townhouses): In premium multi-family housing, differentiation is key. Mosaic shingles offer developers an opportunity to elevate the exterior aesthetic, making units more attractive to potential buyers or renters. The uniform yet distinctive appearance across multiple units creates a cohesive and upscale community feel.

Exemplary Scenarios (Generic Case Studies for Illustrative Experience):

- Coastal Luxury Residence (Southern California): A prominent developer constructing a series of high-end oceanfront homes faced the challenge of selecting a roofing material that could withstand extreme coastal winds, saltwater exposure, and intense UV radiation, while also contributing to the property's luxury aesthetic. Traditional architectural shingles were deemed insufficient for the desired visual impact and long-term durability in this harsh environment. The selection of custom-blended mosaic shingles not only provided the necessary wind uplift resistance (Class H) and UV protection but also delivered a unique, wave-like pattern that harmonized with the oceanic surroundings, significantly increasing the properties' curb appeal and market value. Feedback from real estate agents confirmed that the distinctive roof was a major selling point.

- Historic District Commercial Building Restoration (Mid-Atlantic): A property management firm undertook the restoration of a 1920s commercial building in a protected historic district. The original roof was slate, but replacement with new slate was cost-prohibitive and structurally demanding. The firm opted for mosaic shingles designed to mimic the texture and variegated colors of aged slate. The material provided a Class A fire rating and enhanced impact resistance (Class 4), meeting modern building codes while preserving the building's historical character. The project was completed within budget and ahead of schedule, with the building's façade receiving commendations for its authentic appearance and improved resilience.

- Sustainable Community Development (Southwest USA): A forward-thinking developer aimed to construct a net-zero energy community featuring highly efficient homes. Beyond solar panels, roofing material selection was critical for passive cooling. They chose light-colored mosaic shingles with a high Solar Reflectance Index (SRI > 35). These shingles demonstrably reduced attic temperatures by an average of 15-20°F compared to standard asphalt shingles, significantly reducing cooling loads. The unique mosaic patterns also added a contemporary, eco-conscious aesthetic to the homes, aligning with the community's sustainable branding. Post-occupancy surveys indicated high tenant satisfaction with indoor comfort and lower utility bills.

These examples underscore the versatility and value proposition of mosaic shingles. They are not just roofing materials; they are strategic investments that enhance a building's performance, extend its lifespan, and elevate its aesthetic and market appeal, making them an ideal choice for B2B stakeholders committed to excellence.

Customization and Bespoke Solutions for Mosaic Shingles

In the realm of high-end construction and architectural design, differentiation is paramount. While standard roofing materials offer limited design options, mosaic shingles excel in their capacity for customization, providing architects, designers, and developers with an unprecedented degree of creative freedom. This flexibility allows for the creation of truly bespoke roofing solutions that perfectly align with unique project visions and brand identities.

Tailoring the Aesthetic:

- Color Palette Blending: The most immediate aspect of customization for mosaic shingles lies in the ability to specify unique blends of mineral granules. Manufacturers can often produce custom granule mixes, allowing clients to match specific brand colors, regional architectural styles, or achieve particular visual effects. For instance, a coastal development might opt for blues and grays that mimic ocean hues, while a rustic mountain lodge might choose earth tones and deep greens.

- Pattern and Texture Variation: Beyond color, the actual application pattern of the granules and the layering of the shingle can be customized. This can result in shingles that evoke different materials, such as weathered wood, natural slate, or even abstract artistic designs. The interplay of shadow lines and varied granule sizes contributes to the unique three-dimensional texture that is a hallmark of mosaic shingles.

- Bespoke Cut Patterns: While asphalt shingles typically follow standard cuts (e.g., straight tab, staggered), some manufacturers offer capabilities to create custom cut patterns that further enhance the mosaic effect or achieve a truly unique outline. This advanced customization can significantly elevate the roof's visual impact, making it a focal point of the building's design.

Engineered for Specific Performance Needs:

Customization extends beyond aesthetics to performance. For large-scale B2B projects, specific environmental challenges or regulatory requirements may necessitate tailored solutions:

- Enhanced Impact Resistance: In regions prone to severe hail, mosaic shingles can be engineered with increased asphalt density or specialized granule application techniques to achieve higher UL 2218 Class 4 ratings, providing superior protection and potentially reducing insurance premiums.

- Advanced Cool Roof Properties: For projects focused on energy efficiency and sustainability, manufacturers can develop mosaic shingles with specific high Solar Reflectance Index (SRI) values. This involves selecting lighter-colored, highly reflective granules and optimizing the shingle's composition to minimize heat absorption, contributing to LEED certification or other green building standards.

- Specialized Algae Resistance: In exceptionally humid climates, specific copper-infused granule concentrations can be tailored to provide extended algae resistance warranties, ensuring the roof maintains its aesthetic appeal without unsightly streaking.

The Consultation and Design Process:

Leading manufacturers of mosaic shingles, like CoolRoofMaterials, engage in a collaborative consultation process with B2B clients to translate design concepts into tangible products. This typically involves:

- Initial Design Brief: Understanding the project's architectural style, environmental conditions, performance targets, and aesthetic preferences.

- Material and Color Sample Development: Providing a range of physical samples and digital renderings to visualize potential granule blends and patterns. This iterative process ensures the final selection meets exact specifications.

- Technical Specification Alignment: Working with project engineers and architects to ensure the customized shingle meets all structural, wind, fire, and thermal performance requirements, adhering to relevant building codes and standards (e.g., ASTM, UL, ICC-ES).

- Prototyping and Testing: For highly specialized orders, prototype samples may be produced and subjected to rigorous testing to validate performance before full-scale production begins.

- Logistics and Delivery Planning: Coordinating manufacturing schedules with project timelines to ensure timely delivery of custom orders.

The ability to provide truly bespoke mosaic shingles solutions distinguishes manufacturers who are committed to innovation and client-centric service. This level of customization empowers B2B clients to create roofing systems that are not only high-performing and durable but also uniquely reflect the architectural vision and value of their projects.

Partnering for Success: Manufacturer Selection Criteria and Industry Leadership

Choosing the right manufacturer for mosaic shingles is as critical as selecting the product itself. For B2B decision-makers, a manufacturer is not merely a supplier but a strategic partner whose capabilities, reliability, and commitment to quality directly impact project success and long-term asset value. A robust selection process focuses on criteria that extend beyond product specifications to encompass operational excellence, innovation, and unwavering support.

Key Criteria for Selecting a Mosaic Shingles Manufacturer:

- Proven Quality and Manufacturing Expertise:

- Certifications: Verify adherence to international quality management systems like ISO 9001 and product-specific certifications such as UL, ASTM, and ICC-ES. These indicate consistent product quality and compliance with rigorous performance standards.

- Material Sourcing: Inquire about the origin and quality control of raw materials (fiberglass mat, asphalt, granules). Reputable manufacturers source from trusted suppliers and conduct their own incoming material inspections.

- Manufacturing Process: Understand the manufacturer's technological capabilities in granule blending, lamination, and quality control during production. Advanced facilities with automated processes often yield more consistent and higher-quality mosaic shingles.

- Research and Development (R&D) and Innovation:

- A leading manufacturer actively invests in R&D to improve product performance (e.g., enhanced wind resistance, cool roof technology, extended algae protection) and introduce new aesthetic options for mosaic shingles.

- Look for manufacturers contributing to industry standards or developing proprietary technologies that offer a competitive edge.

- Comprehensive Warranty and Technical Support:

- Warranty Coverage: A robust, clear, and transferable warranty (e.g., Limited Lifetime Warranty for residential, extended commercial warranties) signifies confidence in product longevity. Understand the terms, coverage, and claim process.

- Technical Assistance: Availability of knowledgeable technical support for installation guidance, product specifications, and troubleshooting. This is invaluable for complex commercial projects.

- Logistics and Supply Chain Reliability:

- Delivery Capabilities: Assess the manufacturer's ability to deliver large volumes of mosaic shingles on schedule, especially for time-sensitive projects.

- Inventory Management: Reliable inventory and production planning minimize lead times and avoid project delays.

- Sustainability Practices:

- Increasingly important for B2B clients, look for manufacturers with environmentally responsible practices, including waste reduction, energy efficiency in manufacturing, and availability of recycled content or recyclable products.

- Availability of "cool roof" certified mosaic shingles also aligns with green building objectives.

- Industry Reputation and Experience:

- Review client testimonials, case studies, and industry awards. A long-standing presence and positive reputation in the B2B roofing sector are strong indicators of reliability and expertise.

- Check for significant partnerships with architectural firms, construction companies, or industry associations.

Why Partnering with a Leader Matters:

A manufacturer that consistently meets or exceeds these criteria is not just selling a product; they are offering a complete solution backed by expertise and commitment. For projects leveraging mosaic shingles, this means:

- Reduced Project Risk: High-quality materials and reliable supply chains minimize construction delays and costly reworks.

- Optimized Performance and Longevity: Superior products ensure the roof performs as expected for its entire service life, reducing long-term maintenance burdens.

- Enhanced Aesthetic Value: Access to cutting-edge design and customization options allows for truly distinctive and valuable properties.

- Ongoing Support: Professional technical support and robust warranties provide peace of mind throughout the product's lifespan.

By prioritizing these selection criteria, B2B clients can forge successful partnerships with manufacturers who are dedicated to delivering not only exceptional mosaic shingles but also the comprehensive support necessary for outstanding project outcomes.

Trust and Reliability: Ensuring Your Investment in Mosaic Shingles

In B2B transactions, trust is the cornerstone of enduring partnerships. When investing in specialized roofing materials like mosaic shingles, assurance of quality, reliability, and support throughout the product lifecycle is paramount. A reputable manufacturer demonstrates trustworthiness through transparent policies, robust support systems, and unwavering commitment to customer satisfaction.

Frequently Asked Questions (FAQ) about Mosaic Shingles:

Q1: How do mosaic shingles impact property value?

A1: Mosaic shingles significantly enhance curb appeal due to their unique aesthetic and dimensional texture. This distinctiveness can contribute to higher property valuations, quicker sales, and a stronger competitive edge in the real estate market. Their long lifespan and durability also signal a high-quality investment to potential buyers or tenants.

Q2: Are mosaic shingles more difficult to install than standard shingles?

A2: While the core installation process is similar to architectural shingles, the patterned nature of mosaic shingles may require a slightly more meticulous approach to ensure proper alignment and pattern continuity. Professional, experienced roofing contractors familiar with premium laminated shingles are recommended to achieve the optimal aesthetic outcome.

Q3: Can mosaic shingles be used in cold climates or regions with extreme weather?

A3: Yes, high-quality mosaic shingles are engineered for broad climate suitability. Their advanced asphalt formulations maintain flexibility in cold temperatures, and their multi-layer construction provides superior resistance to high winds (often Class F or H) and hail impact (Class 3 or 4), making them highly resilient against various extreme weather conditions.

Q4: Do mosaic shingles require special maintenance?

A4: Generally, mosaic shingles require similar low maintenance as other asphalt shingles. Regular roof inspections (e.g., annually) to check for debris or minor damage are recommended. Many come with algae resistance, reducing the need for specialized cleaning to remove black streaks.

Q5: What cool roof properties do mosaic shingles offer?

A5: Certain lighter-colored or specially manufactured mosaic shingles can achieve significant Solar Reflectance Index (SRI) values, indicating their ability to reflect sunlight and reduce heat absorption. This contributes to a cooler attic space, lower indoor temperatures, and reduced energy consumption for cooling, aligning with energy efficiency goals and green building initiatives.

Delivery Cycle and Logistics Efficiency:

For B2B projects, timely delivery is paramount to maintaining project schedules and avoiding costly delays. Reputable manufacturers of mosaic shingles prioritize efficient logistics and a robust supply chain:

- Streamlined Order Processing: From initial inquiry to final shipment, processes are optimized for speed and accuracy.

- Transparent Lead Times: Clear communication regarding manufacturing and shipping lead times, especially for custom orders of mosaic shingles.

- Reliable Shipping Partners: Collaboration with established logistics companies ensures secure and on-time delivery to project sites, whether local or international.

- Inventory Management: Advanced inventory systems to manage stock levels for standard products and efficient production scheduling for bespoke orders.

Unwavering Quality Assurance and Warranty Commitment:

A manufacturer's commitment to quality is best demonstrated through its rigorous quality assurance protocols and comprehensive warranty offerings. For mosaic shingles:

- Multi-Stage Quality Control: From raw material inspection to in-process checks and final product testing, strict quality control ensures every shingle meets performance and aesthetic standards. This includes adherence to ASTM, UL, and other relevant certifications.

- Industry-Leading Warranties: High-quality mosaic shingles typically come with robust limited lifetime warranties for residential applications and substantial commercial warranties (e.g., 20-30 years). These warranties cover manufacturing defects and often include extended protection against wind damage and algae growth.

- Clear Warranty Terms: Transparent and easily understandable warranty documents that clearly outline coverage, conditions, and the claims process, providing long-term assurance for the investment.

Dedicated Customer Support and Technical Expertise:

Beyond product delivery, accessible and knowledgeable customer support is vital for ongoing project success and post-installation peace of mind:

- Expert Technical Team: Access to technical specialists who can provide detailed product specifications, installation guidelines, compatibility advice, and troubleshooting assistance.

- Responsive Communication Channels: Multiple avenues for support (phone, email, online portal) ensuring quick and efficient resolution of queries.

- Post-Sales Support: Assistance with warranty claims, product information, and guidance on maintenance to maximize the lifespan of the mosaic shingles.

By offering these comprehensive pillars of trust and reliability, a reputable manufacturer becomes a true partner, safeguarding the client's investment in mosaic shingles and contributing significantly to the overall success and longevity of their projects.

Conclusion: The Future of Roofing Aesthetics with Mosaic Shingles

As the demands of modern architecture and sustainable construction continue to evolve, mosaic shingles stand at the forefront of roofing innovation. They represent a harmonious convergence of cutting-edge manufacturing processes, superior material science, and unparalleled design flexibility. For B2B stakeholders, the decision to specify mosaic shingles is an strategic one, promising not only enhanced structural integrity and long-term performance but also a powerful differentiator in terms of aesthetic appeal and property value.

The detailed exploration of their advanced craftsmanship, stringent quality control adhering to standards like ASTM and UL, and their distinct advantages over traditional 3-tab and architectural shingles, underscores their premium positioning. The ability to customize color blends and patterns further empowers architects and developers to realize truly bespoke visions, transforming a functional necessity into an artistic statement. Furthermore, the commitment of reputable manufacturers to transparent operations, robust warranties, and comprehensive customer support solidifies the investment, offering peace of mind throughout the long lifecycle of these exceptional roofing materials.

Looking ahead, the roofing industry is poised for continued growth driven by climate resilience, energy efficiency mandates, and an increasing appreciation for integrated design. Mosaic shingles are exceptionally well-positioned to capitalize on these trends, offering solutions that meet the highest standards of durability, sustainability, and visual excellence. As cities grow and architectural designs become more daring, the demand for distinctive, high-performance roofing materials will only intensify, cementing the role of mosaic shingles as a cornerstone of future-proof construction.

Choosing mosaic shingles is an investment in a property's enduring beauty, resilience, and economic viability, reflecting a commitment to quality that resonates with discerning clients and contributes to the creation of truly iconic structures.

References

- American Society for Testing and Materials (ASTM) International. ASTM D3462: Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules.

- Underwriters Laboratories (UL) LLC. UL 2218: Standard for Impact Resistance of Prepared Roof Covering Materials.

- Underwriters Laboratories (UL) LLC. UL 790: Standard Test Method for Fire Resistance of Roof Covering Materials.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements.

- Cool Roof Rating Council (CRRC). CRRC 1: Product Rating Program.

- National Roofing Contractors Association (NRCA). The NRCA Roofing Manual: Architectural Metal Flashing, Condensation and Air Leakage Control, and Reroofing.

- Canadian Standards Association (CSA). CSA A123.5: Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules.

- Building Code Standards and Guidelines for Roofing Materials. International Building Code (IBC) and International Residential Code (IRC).

Unveiling Mosaic Shingles: A Paradigm Shift in Roofing Aesthetics and Performance for B2B Applications

In the dynamic landscape of modern construction and architectural design, roofing materials are no longer merely functional components; they are integral elements contributing to a structure's aesthetic appeal, energy efficiency, and long-term resilience. Among the innovative solutions emerging, mosaic shingles represent a significant advancement, offering a distinctive blend of visual sophistication and robust performance. These specialized roofing products are engineered to provide unparalleled design flexibility, allowing architects and developers to achieve unique, high-impact facades that differentiate their projects.

The global roofing market is currently experiencing a robust growth trajectory, driven by increasing construction activities, growing demand for sustainable building materials, and the need for enhanced weather resistance in the face of evolving climatic patterns. Within this expansive market, there's a discernible trend towards premium, design-centric roofing solutions that offer superior longevity and curb appeal. While traditional roofing materials like three-tab and architectural shingles have long dominated the residential and light commercial sectors, the rise of specialized products like mosaic shingles addresses a niche but growing demand for truly unique and high-performance options. This segment is particularly appealing to B2B stakeholders, including luxury home builders, commercial property developers, and institutional project managers, who seek to deliver projects that stand out in a competitive market while ensuring optimal structural integrity and energy efficiency. The unique patterning and multi-layered composition inherent in mosaic shingles provide a depth and texture that is distinct from conventional offerings, making them a preferred choice for landmark projects that require both exceptional visual impact and uncompromising durability. The intricate designs are not merely superficial; they are engineered into the very fabric of the shingle to withstand the rigors of time and environmental exposure.

The Advanced Craftsmanship of Mosaic Shingles: A Deep Dive into Manufacturing Excellence

The manufacturing of mosaic shingles is a sophisticated process that combines advanced material science with precision engineering to produce a product that is both aesthetically compelling and structurally resilient. Unlike conventional shingles, the production of mosaic shingles involves meticulous layering and granulation techniques to achieve their characteristic patterned appearance and enhanced protective qualities. The process begins with carefully selected raw materials, each contributing to the final product's durability, weather resistance, and performance profile.

Core Materials and Their Role:

- Fiberglass Mat: At the heart of every mosaic shingle lies a high-strength, non-woven fiberglass mat. This mat serves as the foundational reinforcement, providing exceptional dimensional stability, resistance to tearing, and resilience against buckling. Its lightweight yet robust nature ensures that the shingles can withstand significant environmental stresses, including thermal expansion and contraction, without imposing excessive structural load on the roof deck. This core component is critical for the long-term integrity of the shingle.

- Asphalt Blend: The fiberglass mat is meticulously impregnated with a specially formulated asphalt blend. This asphalt is oxidized and often modified with polymers to substantially enhance its waterproofing capabilities, flexibility across a wide temperature range, and superior resistance to damaging UV radiation, intense thermal cycling, and brittleness in severe cold weather conditions. The precise quality and composition of this asphalt directly dictate the shingle's long-term performance, self-sealing properties, and its ability to prevent water ingress, which is paramount for protecting the building structure.

- Mineral Granules: The distinctive and intricate aesthetic of mosaic shingles is primarily attributed to the high-quality, ceramic-coated mineral granules meticulously applied to the asphalt surface. These granules fulfill multiple vital and integrated functions:

- UV Protection: They form a robust protective layer, effectively shielding the underlying asphalt from the harmful effects of ultraviolet rays, which are a primary cause of premature aging, cracking, and deterioration in conventional asphalt shingles.

- Aesthetics: Available in an extensive spectrum of vibrant and muted colors, these granules are strategically blended and applied in complex, multi-layered patterns to create the characteristic 'mosaic' effect. This results in unparalleled visual depth, texture, and a high degree of customization for architects and designers.

- Fire Resistance: The inherent properties of the ceramic coating, combined with the dense layer of granules, significantly enhance the shingle's resistance to external fire exposure, contributing to higher fire ratings.

- Algae Resistance: Many modern granule formulations incorporate precisely measured quantities of copper or zinc particles. These metallic elements act as effective biostats, providing long-term, sustained protection against unsightly blue-green algae growth, particularly prevalent in warm, humid climates, thereby preserving the roof's aesthetic integrity and minimizing maintenance.

- Release Film: A thin, finely granulated non-adhesive release film is applied to the back surface of the shingle. This crucial layer serves to prevent shingles from sticking together during the stacking, packaging, and shipping processes, ensuring easy and efficient separation during installation on the job site.

The Manufacturing Process: Precision and Innovation

The manufacturing process for mosaic shingles involves several meticulously controlled and highly automated stages, designed to ensure consistent quality, superior performance, and the precise execution of their unique aesthetic:

- Mat Saturation: The continuous fiberglass mat is unrolled from large spools and fed into a sophisticated coater. Here, it is thoroughly and uniformly saturated with the hot, polymer-modified asphalt blend. This deep impregnation is essential for waterproofing the mat, binding the reinforcing fibers, and preparing the surface for granule adhesion.

- Granule Application: This stage is the pinnacle of the mosaic shingles manufacturing process. Unlike single-layer granule application common in basic shingles, specialized machinery precisely applies multiple colors and sizes of mineral granules in a predetermined, complex pattern. This is often achieved using proprietary robotic systems or digitally controlled hoppers that distribute granules with extreme accuracy, creating the unique dimensional and 'mosaic' aesthetic. This advanced patterning is what truly differentiates mosaic shingles visually.

- Lamination and Bonding: For the multi-layered or 'laminated' structure characteristic of mosaic shingles, additional layers of asphalt-coated mats are precisely aligned and bonded together. This bonding typically occurs under controlled heat and pressure, often employing specialized thermal or adhesive processes. This lamination significantly enhances the shingle's overall thickness, rigidity, and structural integrity, directly contributing to its superior wind resistance, impact resistance, and extended durability.

- Cooling and Curing: Following lamination, the continuous shingle material passes through cooling zones, where the asphalt solidifies and the granules firmly embed into the surface. Controlled cooling prevents warping, ensures proper adhesion of all layers, and stabilizes the shingle's dimensions, preparing it for cutting.

- Cutting and Packaging: The cooled and cured shingle material is then cut into individual shingles or pre-configured strips using high-precision rotary cutting equipment. Integrated thermal sealant strips are simultaneously applied to the underside of the shingle; these strips will activate under solar heat after installation, creating a robust bond to adjacent shingles and enhancing wind uplift resistance. Finally, the finished mosaic shingles are precisely stacked, bundled, and packaged according to industry standards for distribution and transport.

Rigorous Testing and Quality Assurance: Adherence to Global Standards

To ensure the highest levels of quality, performance, and long-term reliability, mosaic shingles undergo stringent testing at every critical stage of their production cycle. Reputable manufacturers adhere to a comprehensive suite of international and national standards, providing irrefutable assurance of product reliability, safety, and compliance with building codes. Key standards rigorously applied include:

- ASTM D3462 (Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules): This fundamental and widely recognized standard outlines the minimum comprehensive requirements for asphalt shingles, encompassing critical aspects such as material composition, precise dimensions, weight per unit area, and essential physical properties, serving as a baseline for quality.

- ASTM D3161 (Standard Test Method for Wind Resistance of Asphalt Shingles (Fan Induced Method)): This is a crucial performance test that evaluates the shingle's ability to withstand high wind forces. It simulates real-world wind conditions to assess the integrity of the shingle's self-seal strip and its resistance to blow-off, classifying shingles into various wind resistance classes (e.g., Class F for 110 mph, Class H for 150 mph).

- UL 2218 (Standard for Impact Resistance of Prepared Roof Covering Materials): This vital test classifies shingles based on their resistance to impact from falling objects, specifically designed to simulate hail. Shingles are rated from Class 1 to Class 4, with Class 4 being the highest rating, indicating superior resistance to hail damage. Many premium mosaic shingles are engineered to achieve these higher impact resistance ratings, providing enhanced protection.

- UL 790 (Standard Test Method for Fire Resistance of Roof Covering Materials): This test determines the shingle's resistance to external fire exposure, classifying them with A, B, or C ratings. Class A is the highest and most stringent fire resistance rating, signifying superior protection against flame spread and external fire penetration, which is critical for building safety.

- CSA A123.5 (Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules): This is the equivalent Canadian standard to ASTM D3462, ensuring that products manufactured for or distributed within North American markets meet consistent quality and performance benchmarks.

- ISO 9001 (Quality Management Systems): While not product-specific, ISO 9001 certification indicates a manufacturer's profound commitment to establishing and maintaining consistent quality management processes across all operational facets, from rigorous raw material procurement and meticulous production to comprehensive finished product inspection and customer service.

Service Life and Applicable Industries:

Thanks to the application of advanced materials, sophisticated manufacturing techniques, and adherence to rigorous testing, high-quality mosaic shingles offer an exceptional and extended service life. Typically, these premium roofing solutions are warranted for 30 to 50 years, often backed by robust limited lifetime warranties for residential applications. Their superior durability and distinctive aesthetic appeal make them exceptionally suitable for a diverse and demanding range of applications, extending well beyond typical residential roofing scenarios:

- High-End Residential Construction: For luxury homes, bespoke custom builds, and exclusive residential developments where architectural distinctiveness, unparalleled curb appeal, and long-term asset value are paramount.

- Commercial and Public Buildings: Applicable to a wide array of structures such as schools, government buildings, community centers, and upscale retail spaces where a premium, highly durable, and aesthetically pleasing roof is desired to enhance corporate image, public perception, and long-term property value.

- Hospitality Sector: Hotels, resorts, and vacation properties frequently utilize mosaic shingles to create inviting and memorable exteriors that convey a strong sense of quality, luxury, and sophisticated design, contributing to the overall guest experience.

- Specialized Architectural Projects: Any project requiring a truly unique roof design, a specific visual effect, or an artistic statement benefits immensely from the advanced customization potential inherent in mosaic shingles.

- Renovation and Restoration of Premium Properties: Ideal for upgrading existing high-value structures, providing a modern yet timeless aesthetic while simultaneously improving crucial performance metrics such as weather resistance, energy efficiency, and overall structural resilience.

Advantages in Typical Application Scenarios:

- Enhanced Curb Appeal and Property Value: The striking visual patterns, intricate granule blends, and profound dimensional texture of mosaic shingles dramatically boost a property's aesthetic appeal. This translates directly into increased market value and a stronger competitive position for developers and property managers focused on maximizing asset returns and attracting high-end clientele.

- Superior Weather Resistance: With multiple engineered layers, high-quality fiberglass mats, and advanced asphalt formulations, these shingles offer exceptional resistance to severe weather conditions including high winds, damaging hail impact, and heavy rainfall. This significantly reduces the risk of storm-related damage and associated costly repair work, providing crucial peace of mind for building owners, facility managers, and insurance providers.

- Comprehensive UV and Algae Protection: The high-quality ceramic granules provide superior, long-lasting protection against harmful UV radiation, which critically extends the asphalt's lifespan and prevents premature degradation. Furthermore, integrated algae-resistant granules, often infused with copper, maintain the roof's pristine, streak-free appearance over many decades, minimizing the need for burdensome maintenance efforts and associated costs.

- Potential for Significant Energy Efficiency: Certain lighter-colored or specially formulated mosaic shingles can be designed with advanced "cool roof" properties. These materials possess high solar reflectance and thermal emittance, meaning they reflect more sunlight and absorb substantially less heat. This effectively reduces attic temperatures and consequently lowers cooling costs for the entire building, representing a significant operational expenditure advantage for large commercial, institutional, and industrial complexes.

- Exceptional Durability and Longevity: The robust, multi-layered construction and unwavering adherence to rigorous industry testing standards ensure that mosaic shingles provide a profoundly long-lasting and reliable roofing solution. This extended lifespan significantly reduces the frequency and considerable cost of roof replacement over the building's entire operational lifecycle, leading to substantial long-term savings for B2B investors.

Technical Specifications and Performance Metrics of Mosaic Shingles

Understanding the precise technical specifications of mosaic shingles is an indispensable requirement for architects, structural engineers, and purchasing managers to make thoroughly informed and strategic decisions. These quantified parameters are crucial as they meticulously detail the product's expected performance, inherent durability, and specific suitability for diverse environmental conditions and demanding project requirements. Below is a comprehensive table outlining the typical, high-level parameters for high-quality mosaic shingles, meticulously followed by an in-depth explanation of the profound significance of each critical parameter.

Key Technical Parameters for Mosaic Shingles:

| Parameter | Typical Specification (Metric/Imperial) | Significance for B2B Stakeholders |

|---|---|---|

| Material Composition | High-strength fiberglass mat, highly oxidized and polymer-modified asphalt, ceramic-coated mineral granules (custom multi-color blends), non-adhesive release film. | The precise engineering of these components ensures exceptional dimensional stability, robust waterproofing capabilities, superior UV protection, enhanced fire resistance, and the creation of their distinct, premium aesthetic. This composition forms the very core of the product's long-term performance and durability. |

| Overall Thickness | 5.5 mm - 7.0 mm (0.22 - 0.28 inches) | Directly indicates the shingle's inherent robustness, structural integrity, and superior dimensional stability. Thicker shingles are consistently correlated with higher impact resistance, improved longevity, and a more pronounced, premium aesthetic due to their substantial profile. |

| Weight per Square (100 sq ft) | 300 - 450 lbs (136 - 204 kg) | This metric directly reflects the material density and inherent durability of the shingle. A higher weight typically signifies a greater quantity of asphalt and granules, directly contributing to superior wind resistance, enhanced impact protection, and overall longevity. This parameter is also crucial for precise structural load calculations for the roof deck. |

| Wind Resistance Rating | ASTM D3161 Class F (110 mph / 177 km/h) or ASTM D7158 Class H (150 mph / 241 km/h) | Absolutely crucial for projects situated in high-wind zones or hurricane-prone areas. Higher ratings fundamentally reduce the risk of shingle blow-off during severe weather events, thereby minimizing costly repair or replacement expenses and ensuring the long-term structural integrity of the entire roofing system. |

| Fire Resistance Rating | UL 790 Class A | This represents the highest possible fire resistance rating attainable for roofing materials, making it an essential compliance factor for safety regulations in both commercial and residential building codes. It significantly reduces the risk of external fire spread, enhancing overall building safety. |

| Impact Resistance Rating | UL 2218 Class 3 or Class 4 | Indicates the shingle's exceptional ability to withstand severe hail damage. Class 4 offers the highest level of superior protection, often leading to reduced insurance premiums for property owners and significantly lower long-term maintenance and repair costs in regions frequently affected by hail. |

| Algae Resistance Warranty | 10-20 years (depending on manufacturer and specific granule type) | This warranty guarantees the prevention of unsightly black streaks caused by algae growth, thereby preserving the roof's pristine aesthetic appeal over many years. This significantly reduces the need for frequent and costly cleaning, which is highly beneficial for property and facility managers. |

| Limited Lifetime Warranty | 50 years (pro-rated) for residential applications; 20-30 years for commercial applications | A strong and comprehensive warranty provided by the manufacturer signifies immense confidence in the product's longevity and performance. It offers long-term financial protection for the investment, which is absolutely crucial for meticulous budgeting, risk management, and overall project viability. |

| Cool Roof Performance (SRI) | Solar Reflectance Index (SRI) > 29 (for specific colors/products); often higher for lighter custom blends. | Directly contributes to enhanced building energy efficiency by significantly reducing the heat island effect and lowering indoor cooling loads. This can result in substantial energy cost savings and helps meet stringent green building certifications (e.g., LEED, Title 24 compliance), which is increasingly important for sustainable construction projects. |

These specifications are not merely abstract numbers; they fundamentally represent the engineering integrity, meticulous craftsmanship, and expected long-term performance of the entire roofing system. For astute B2B decision-makers, meticulously evaluating these parameters is absolutely essential for ensuring that the chosen roofing material precisely aligns with project budgets, stringent building codes, realistic long-term maintenance projections, and the desired architectural and aesthetic outcomes. The inherently robust nature of mosaic shingles, comprehensively reflected and guaranteed by these precise specifications, unequivocally positions them as the definitive premium choice for discerning projects that demand both exceptional beauty and uncompromising resilience.

Image: A close-up view showcasing the intricate multi-layered texture and varied color granules of high-performance mosaic shingles, highlighting their unique aesthetic.

Differentiating Roofing Solutions: Mosaic Shingles vs. Traditional Alternatives

When making critical decisions about roofing materials, B2B professionals are presented with a myriad of choices, each possessing its own distinct set of characteristics, inherent advantages, and specific limitations. While mosaic shingles offer a clearly defined and superior value proposition, it is absolutely crucial to possess a comprehensive understanding of how they meticulously compare to more traditional asphalt shingle types, specifically the ubiquitous three-tab (3-tab) and the widely adopted architectural (laminate) shingles. This detailed comparison will directly and thoroughly address the common industry questions that procurement managers and architects frequently pose: what is the difference between 3 tab and architectural shingles, what is the difference between 3 tab and laminate shingles, what is the difference between 3 tab shingles and architectural, and conversely, what is the difference between architectural shingles and 3 tab, all while precisely positioning mosaic shingles within this established spectrum of roofing solutions.

Comprehensive Comparison Table: 3-Tab, Architectural, and Mosaic Shingles

| Feature | 3-Tab Shingles | Architectural (Laminate) Shingles | Mosaic Shingles |

|---|---|---|---|

| Aesthetic Appeal | Flat, uniform, and two-dimensional appearance; presents a classic, fundamental, and utilitarian look. | Distinctly dimensional and textured appearance; expertly simulates the natural look of traditional wood shakes or elegant slate; characterized by varied and appealing shadow lines. | Offers a highly distinctive, intricate, and artistic array of patterns; sophisticated multi-color granule blends create unparalleled visual depth and a truly unique architectural statement; represents a premium aesthetic benchmark. |

| Construction | Features a single-layer asphalt shingle design with precisely cut-outs along the bottom edge to visually create the illusion of three distinct tabs. | Employs a multi-layer (laminated) construction, typically consisting of two or more layers of fiberglass mat and asphalt meticulously bonded together for enhanced durability. | Utilizes an advanced, robust multi-layer (laminated) construction, further enhanced by proprietary and specialized granule application techniques to achieve their signature intricate and patterned designs. |

| Thickness/Weight | Represents the thinnest and lightest option among asphalt shingles (approximately 200-240 lbs/square). | Significantly thicker and notably heavier than 3-tab shingles (approximately 250-400 lbs/square), indicating increased material content. | The thickest and heaviest option (approximately 300-450 lbs/square), which is a clear indicator of their robust composition, superior material density, and enhanced durability. |

| Durability/Lifespan | Generally offers a shorter lifespan of 20-25 years; more susceptible to wind uplift and environmental degradation. | Provides an extended lifespan of 30-50 years; significantly better wind and impact resistance directly attributed to its robust laminated construction. | Offers a superior lifespan of 50+ years, often backed by lifetime limited warranties; boasts exceptional wind, impact, and UV resistance; its enhanced longevity is a direct result of advanced materials and meticulous construction. |

| Wind Resistance | Typically rated to withstand basic wind speeds of 60-80 mph. | Generally rated for higher wind speeds, typically 110-130 mph (often achieving ASTM D3161 Class F). | Designed for superior wind performance, typically rated for 110-150 mph (achieving ASTM D3161 Class F to D7158 Class H), offering exceptional protection against extreme weather events. |

| Cost (Material) | Represents the lowest initial material cost, making it a budget-conscious choice. | Falls into the mid-range cost category; significantly higher than 3-tab, but generally lower than specialized premium options like mosaic. | Represents a premium initial material cost; the highest investment due to their specialized design, advanced materials, and inherently enhanced performance attributes. |

| Installation Complexity | Considered the simplest and fastest type of asphalt shingle to install due to its uniform design. | Generally similar to 3-tab shingles, but may require slightly more careful attention due to their random tab alignment and multi-layer nature. | May necessitate more precise alignment and careful handling to ensure the integrity and continuity of their intricate pattern, but broadly comparable in method to architectural shingles for skilled installers. |

| Application Suitability | Best suited for budget-driven residential projects, temporary structures, rental properties, or utility buildings where cost is the primary driver. | Ideal for standard residential construction, light commercial buildings, and homeowners seeking significantly enhanced curb appeal and superior durability compared to 3-tab. | The preferred choice for high-end residential, luxury commercial, custom architectural projects, and properties demanding a truly unique visual impact combined with superior long-term performance and resilience. |

Key Distinctions and Value Propositions:

The fundamental and most significant difference among these various shingle types lies in their underlying construction methodology and the resulting aesthetic appeal and performance attributes they deliver:

- 3-Tab Shingles: These represent the most basic and economically entry-level asphalt shingle option. They are uniquely characterized by their single-layer construction and standardized cut-outs that are designed to create the visual illusion of three individual tabs when installed. Their inherently flat appearance offers very little dimensional depth, and their comparatively lighter weight generally translates to lower wind resistance capabilities and a shorter overall lifespan, typically ranging from 20 to 25 years. They primarily serve as a cost-effective, straightforward roofing solution but notably lack the advanced performance features and the sophisticated aesthetic appeal found in their more advanced counterparts. This description directly addresses the core question of what is the difference between 3 tab and architectural shingles by highlighting their basic structure and two-dimensional visual profile.

- Architectural (Laminate) Shingles: Also widely and interchangeably known as laminate shingles, these represent a substantial and widely adopted upgrade from the simpler 3-tab design. They are meticulously constructed with multiple layers of asphalt and robust fiberglass matting, which are precisely bonded together to create a notably thicker, more structurally robust, and inherently dimensional product. This innovative multi-layered design provides a far more varied and textured appearance that expertly mimics the natural look of premium materials such as traditional wood shakes or elegant slate, thereby offering significantly enhanced curb appeal and architectural interest. The increased mass and superior bonding inherent in their construction dramatically improve their wind resistance (often certified up to 130 mph) and significantly extend their lifespan, typically ranging from 30 to 50 years. The terms 'architectural' and 'laminate' are indeed often used interchangeably within the industry, directly and comprehensively answering questions like what is the difference between 3 tab and laminate shingles and what is the difference between 3 tab shingles and architectural by emphasizing their superior layered construction and significantly enhanced aesthetic and performance attributes.

- Mosaic Shingles: Building upon the advanced foundational technology of architectural shingle manufacturing, mosaic shingles elevate both aesthetic possibilities and performance capabilities to an unparalleled premium level. While they share the robust laminated construction characteristic of architectural shingles, they distinguish themselves profoundly through proprietary and specialized granule application techniques that create intricate, deliberate, and often custom-designed patterns using multi-color granule blends. This results in a truly unique, artistic, and highly dimensional roof surface that simply cannot be replicated by standard architectural shingles, offering a bespoke architectural statement. Furthermore, mosaic shingles frequently incorporate higher-grade raw materials and more sophisticated, precision-driven manufacturing processes, leading to demonstrably superior impact resistance (often achieving Class 4 UL 2218 certifications), even higher wind resistance ratings, and significantly extended product warranties. Their primary and compelling value proposition lies in their ability to deliver an unparalleled visual impact combined with exceptional long-term durability, making them the ideal choice for high-profile projects where unique aesthetics and uncompromising performance are paramount. This detailed comparison directly addresses what is the difference between architectural shingles and 3 tab and further extends the understanding to the distinct and superior advantages of the mosaic shingle options.

For B2B entities, the critical choice among these various asphalt shingle types often distills down to meticulously balancing initial budget constraints with long-term performance requirements and the desired architectural aesthetic outcomes. While 3-tab shingles present the lowest initial material cost, their shorter operational lifespan and notably lower resistance to environmental elements may ultimately lead to higher long-term maintenance expenses and more frequent, costly replacement cycles. Architectural shingles capably provide a strong and balanced middle-ground solution, delivering a commendable equilibrium of cost-effectiveness, enhanced aesthetics, and improved durability. However, for those specific projects that demand a truly signature look, uncompromising superior protection against extreme weather, and a definitive long-term investment that maximizes asset value, mosaic shingles unequivocally stand out as the definitive, ultimate premium roofing solution, offering an unmatched blend of artistic expression and advanced engineering excellence that transforms the roof into a defining architectural feature.

Application Scenarios and Exemplary Case Studies

The unique and compelling combination of aesthetic versatility and robust, enduring performance positions mosaic shingles as an unequivocally premier choice across a diverse range of demanding B2B application scenarios. Their inherent ability to deliver a distinct and captivating visual appeal, meticulously coupled with exceptional durability and resilience, makes them highly sought after in projects where superior curb appeal, extended longevity, and minimal long-term maintenance are critical drivers for maximizing property value and ensuring occupant satisfaction.

Key Application Scenarios:

- Luxury Residential Estates and Gated Communities: For the construction of high-end custom homes, bespoke luxury residences, and exclusive residential developments, mosaic shingles are meticulously chosen to cultivate a sophisticated, individualized, and visually striking look that profoundly enhances overall property value and market appeal. Their inherent dimensional texture and richly varied color patterns provide an undeniable architectural statement, effectively setting these premium properties apart in an increasingly competitive luxury real estate market. Discerning developers consistently leverage the unique aesthetic appeal and superior performance of mosaic shingles to attract affluent buyers who are specifically seeking distinctive design elements and uncompromisingly premium building materials.

- Boutique Commercial Properties and High-End Hospitality Venues: Upscale hotels, exclusive resorts, high-end retail establishments, and specialized commercial buildings frequently utilize mosaic shingles to project a compelling image of unparalleled quality, sophistication, and distinctiveness. In these applications, the roof transcends its functional role to become an integral and defining component of the brand identity, significantly contributing to the overall guest or customer experience. For instance, a boutique hotel aiming for a unique, artisanal aesthetic might meticulously select custom-blended mosaic shingles to perfectly complement its overarching design narrative, thereby ensuring the property not only stands out visually but also provides optimal operational performance for many decades.