សីហា . 28, 2025 04:00 Back to list

Architectural Asphalt Shingles: Durable, Stylish Laminated Roofing

Industry Trends and Market Dynamics for Advanced Roofing Solutions

The roofing industry is undergoing a significant transformation, driven by demands for enhanced durability, aesthetic versatility, and sustainable performance. Within this evolving landscape, asphalt shingles architectural solutions are at the forefront of innovation, offering a compelling blend of traditional appeal and modern engineering. Key trends include the increasing adoption of eco-friendly materials, advancements in manufacturing processes to improve longevity and resilience, and the integration of smart technologies for energy efficiency. The market is also witnessing a surge in demand for products that can withstand extreme weather events, making performance-driven roofing solutions, such as laminate roofing, increasingly critical for both residential and light commercial sectors.

Furthermore, architectural design preferences are shifting towards more sophisticated profiles and color palettes that mimic natural materials like slate or wood shakes, without the associated maintenance burden. This trend directly fuels the growth of high-definition laminated architectural shingles, which provide superior visual depth and curb appeal. Regulatory changes and homeowner awareness regarding energy efficiency and disaster preparedness are also propelling the market towards products with higher impact resistance ratings and cool roof capabilities. The emphasis on long-term value, reduced lifecycle costs, and comprehensive warranties continues to shape purchasing decisions for B2B stakeholders, from builders to property managers and architects.

Detailed Manufacturing Process of Architectural Laminated Shingles

The production of asphalt shingles architectural is a sophisticated, multi-stage process engineered for precision and durability. It combines advanced materials with rigorous manufacturing techniques to ensure superior performance and aesthetic quality.

Process Flow Diagram:

- 1. Fiberglass Mat Acquisition: High-quality, non-woven fiberglass mat serves as the core, providing strength and dimensional stability. Adherence to ISO 9001 standards for raw material sourcing is crucial.

- 2. Asphalt Saturation & Coating: The fiberglass mat is passed through a precisely controlled asphalt saturator, fully impregnating it. This saturated mat is then coated with weather-resistant asphalt on both sides. The asphalt is often modified with polymers to enhance flexibility and resistance to thermal shock. This casting process is carefully monitored for uniform thickness and consistency.

- 3. Mineral Granule Application: Ceramic-coated mineral granules are embedded into the asphalt coating while it is still hot. These granules provide critical UV protection, fire resistance, and the desired aesthetic. Different granule blends are used to create the multi-dimensional look characteristic of laminated roof shingles. This step requires precise dispensing and even distribution.

- 4. Cooling and Curing: The shingle material is cooled rapidly to set the asphalt and granules, followed by a controlled curing period to optimize material stability and adhesion.

- 5. Cutting and Lamination: Large sheets are precisely cut into individual shingle strips. For architectural shingles, multiple layers of shingle material are laminated together using specialized adhesives, creating the distinctive "laminated" or "dimensional" effect. This lamination, often achieved through automated pressing (a form of forging for composite materials), significantly increases tear strength and wind resistance, far exceeding standard 3-tab shingles. CNC machining ensures consistent shingle profiles.

- 6. Quality Control & Testing: Throughout the entire process, comprehensive testing is conducted. This includes ASTM D3462 for tear strength and flexibility, ASTM D3161 (Class F or H) for wind resistance, and ASTM E108 for fire resistance (typically Class A). Batch samples undergo accelerated weathering tests to simulate long-term performance.

- 7. Packaging: Finished shingles are stacked and packaged for distribution, ensuring protection during transit.

Materials & Technical Specifications:

- Core Material: High-strength, non-woven fiberglass mat (typically 120-150 g/m²).

- Asphalt: Oxidized or polymer-modified asphalt, engineered for optimal waterproofing, adhesion, and UV stability.

- Granules: Ceramic-coated basalt or slate granules, providing exceptional UV protection, aesthetic color, and fire resistance. Algae-resistant granules (copper-infused) are often included.

- Adhesive: SBS or APP modified asphalt laminating adhesives for robust layer bonding.

Service Life & Target Industries:

The typical service life for well-installed laminated comp shingle systems ranges from 30 to 50 years, often backed by extended warranties. These systems are highly adaptable and serve a diverse range of target industries, including:

- Residential Construction: Single-family homes, multi-family dwellings, custom residences.

- Commercial & Institutional: Light commercial buildings, schools, churches, community centers, and property management portfolios seeking durable and aesthetically pleasing roofing solutions.

- Hospitality: Hotels and resorts where aesthetic appeal and long-term performance are critical.

Advantages in Typical Application Scenarios:

- Enhanced Energy Efficiency: Certain architectural shingles with reflective granules contribute to cooler roof temperatures, reducing HVAC loads and energy consumption, particularly relevant in warmer climates.

- Superior Wind Uplift Resistance: The multi-layer lamination and robust adhesive strips provide exceptional resistance to high winds (often rated for 130 mph or higher), crucial for regions prone to severe weather.

- Corrosion Resistance: As non-metallic roofing systems, these shingles are inherently resistant to rust and chemical corrosion, maintaining integrity in various environmental conditions.

- Impact Resistance: Available Class 4 impact-resistant ratings (UL 2218) significantly reduce damage from hail, offering substantial insurance benefits in some regions.

- Algae Resistance: Copper-infused granules effectively inhibit the growth of blue-green algae, preventing unsightly streaks and maintaining aesthetic quality over time.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of asphalt shingles architectural is paramount for B2B decision-makers. These parameters dictate a product's suitability for specific projects, its long-term performance, and compliance with building codes and insurance requirements.

Typical Product Specification Table: Laminated Shingles

These specifications highlight the robust engineering behind modern laminated architectural shingles. The high weight per square typically correlates with greater durability and material thickness, while superior wind and fire ratings are crucial for safety and compliance. Optional impact resistance offers significant protection in hail-prone areas, a key consideration for property owners and insurance providers.

Application Scenarios and Strategic Placement

The versatility and performance characteristics of asphalt shingles architectural make them ideal for a broad spectrum of roofing projects. Their aesthetic appeal, combined with advanced protective features, allows for strategic application across various sectors.

- High-End Residential Developments: For luxury homes and custom builds, architectural shingles provide the desired premium aesthetic and robust performance that aligns with investment value. Their multi-dimensional appearance enhances curb appeal significantly.

- Multi-Family Housing & Condominiums: Durability and low maintenance are critical for property managers overseeing multi-unit complexes. Laminate roofing offers an excellent balance of cost-effectiveness, long lifespan, and visually appealing options that withstand common urban and suburban environmental stressors.

- Light Commercial Structures: Businesses such as boutique shops, small office buildings, and restaurants often choose architectural shingles for their attractive appearance and proven weather resistance, ensuring a professional and inviting exterior.

- Renovation and Re-roofing Projects: For existing properties, laminated architectural shingles are a popular choice to upgrade both the aesthetics and protective capabilities of an aging roof, often improving property value and energy efficiency.

- Areas Prone to Severe Weather: In regions susceptible to high winds, hail, or intense UV radiation, the enhanced wind resistance, impact rating options, and UV protection of high-quality architectural shingles offer superior protection compared to conventional roofing materials.

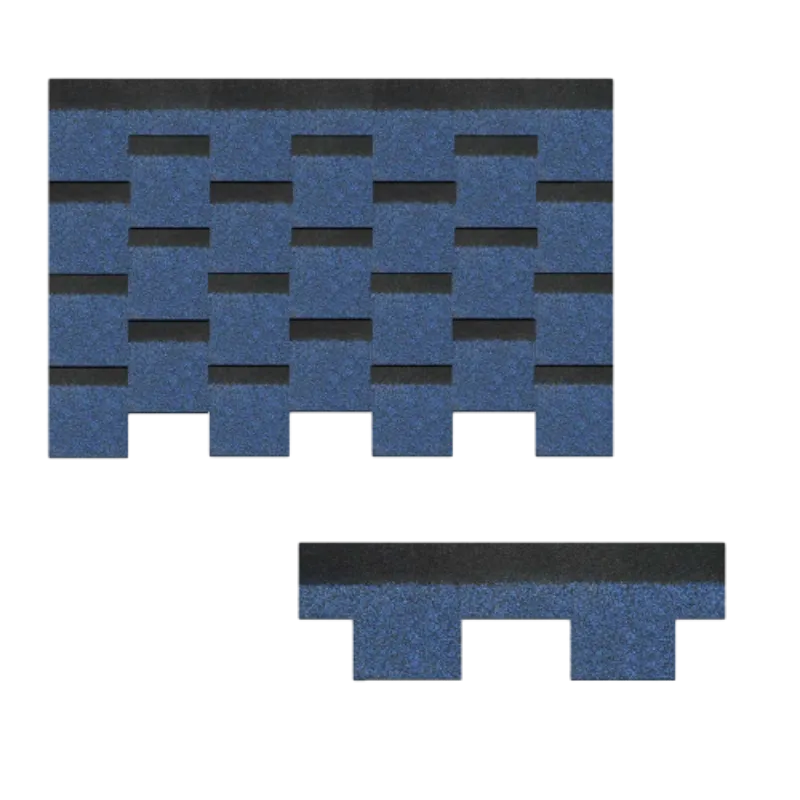

Image: Illustrative example of high-definition asphalt shingles architectural enhancing property aesthetics and protection.

Technical Advantages: Unpacking the Benefits

The technical advantages of modern asphalt shingles architectural extend far beyond their visual appeal, offering substantial performance benefits that translate into long-term savings and enhanced property protection. The layered construction and advanced material science contribute to a superior roofing system.

- Exceptional Durability and Longevity: The multi-layer, laminated design significantly increases the shingle's overall mass and structural integrity, making it highly resistant to tearing, cracking, and general wear-and-tear. This inherent strength contributes to their extended lifespan, often 30-50 years, surpassing traditional 3-tab shingles.

- Superior Wind Resistance: Specialized adhesive sealants and heavy-duty construction enable laminated roof shingles to withstand wind speeds up to 130 mph, minimizing the risk of blow-offs during severe storms. This is achieved through enhanced granule adhesion and the robust bonding of the shingle layers.

- Advanced Weather Protection: The dense mineral granule layer provides robust UV protection, preventing premature asphalt degradation and maintaining color stability. The asphalt formulation itself is engineered for superior water shedding and resistance to thermal cycling.

- Aesthetic Versatility and Curb Appeal: The dimensional, sculpted appearance mimics natural wood shakes or slate, providing a premium look that enhances property value. Available in a wide array of colors and profiles, they offer design flexibility for architects and builders.

- Impact Resistance Options: Many architectural shingles offer UL 2218 Class 3 or Class 4 impact resistance, demonstrating exceptional resilience against hail and debris, which can lead to reduced insurance premiums in eligible areas.

- Fire Safety: With a consistent Class A fire rating (the highest available for roofing materials), these shingles provide excellent protection against external fire sources.

- Algae and Fungal Resistance: Integrating copper or zinc granules into the top layer provides continuous, long-term defense against unsightly blue-green algae streaks and fungal growth, maintaining the roof's clean appearance.

Vendor Comparison: Evaluating Leading Laminated Shingle Providers

Selecting the right vendor for laminated comp shingle solutions is a critical decision for B2B procurement. A comprehensive comparison goes beyond initial cost, focusing on product quality, warranty coverage, certifications, and support. Below is a comparative overview of hypothetical leading vendors, illustrating key differentiators.

Laminated Shingle Vendor Comparison Table:

This table illustrates how distinct vendor offerings can cater to different project requirements and budget constraints. Premium vendors (like "Vendor A") often invest more in R&D for advanced material formulations, extended warranties, and specific features like Class 4 impact resistance or cool roof technology. While "Vendor C" might offer a more attractive initial price point, it's crucial to evaluate the total cost of ownership, including expected lifespan, maintenance, and potential insurance benefits or liabilities, for any laminate roofing project.

Customized Solutions for Unique Project Requirements

Recognizing that every B2B project has unique architectural, environmental, and budgetary considerations, leading manufacturers of asphalt shingles architectural offer a range of customization options. These tailored solutions ensure optimal performance and aesthetic integration for diverse applications.

- Color and Style Matching: Beyond standard color palettes, specialized blends can be developed to match historical aesthetics, corporate branding, or specific architectural visions. This includes advanced granule blending techniques to create unique color transitions and depth.

- Performance Enhancements: For projects in extreme climates, customized solutions can include shingles with augmented layers for increased wind resistance (e.g., higher bond strength adhesives, thicker fiberglass mats), enhanced impact resistance, or specific cool roof properties to meet local energy codes.

- Specialized Coatings: Some manufacturers offer custom asphalt formulations or granule coatings for specific needs, such as improved algae resistance for humid climates or enhanced reflective properties for heat island reduction.

- Accessory Systems Integration: Custom solutions often extend to the entire roofing system, including matching starter shingles, hip and ridge caps, and specialized underlayments that are engineered to work cohesively with the primary laminated architectural shingles for maximum protection and longevity.

- Project-Specific Certifications: For large-scale developments or government projects, manufacturers can assist in providing documentation and achieving project-specific certifications (e.g., LEED contributions, specialized wind uplift approvals for hurricane zones).

Engaging early with manufacturers to discuss project specifications allows for the development of bespoke solutions that precisely address technical challenges and aesthetic goals, ensuring a highly optimized and cost-effective roofing system.

Application Case Studies: Real-World Successes

These case studies illustrate the practical benefits and successful implementation of laminated comp shingle solutions in diverse real-world scenarios, showcasing their durability, aesthetic appeal, and performance.

Case Study 1: Coastal Residential Community Redevelopment

Client: "Oceanview Estates Development Group"

Challenge: A new development of 50 luxury homes located in a high-wind coastal zone required a roofing material that could withstand hurricane-force winds (up to 150 mph) and resist salt-air corrosion, while also offering a premium aesthetic to match the upscale properties.

Solution: Class H wind-rated asphalt shingles architectural with a polymer-modified asphalt formulation were specified. These shingles also featured copper-infused granules for enhanced algae and fungal resistance, critical in humid coastal environments. The chosen style mimicked natural cedar shakes, providing a sophisticated appearance.

Outcome: The roofing system has successfully endured multiple tropical storms over five years with zero shingle loss, providing residents with peace of mind. The aesthetic consistency has significantly boosted property values, and the algae resistance has maintained the roofs' pristine appearance without aggressive cleaning.

Case Study 2: Historical Building Renovation - "The Grand Library"

Client: "City Historical Preservation Committee"

Challenge: The roof of a 100-year-old municipal library needed replacement. The committee required a material that would honor the building's historical aesthetic, provide superior longevity, and meet modern building codes for fire and wind resistance, all within a constrained public budget.

Solution: Custom-blended laminated roof shingles were selected. The manufacturer worked closely with the committee to create a granule blend that replicated the variegated color and texture of the original slate roof, but at a fraction of the cost. The shingles also provided a Class A fire rating and 110 mph wind resistance.

Outcome: The renovation received widespread praise for its faithful adherence to historical aesthetics while integrating modern performance. The new asphalt shingles architectural system is projected to last over 40 years, significantly reducing future maintenance costs for the city and ensuring the preservation of a beloved landmark.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between architectural and 3-tab asphalt shingles?

A: Architectural shingles, also known as laminated architectural shingles, are constructed with multiple layers of asphalt and granules, creating a thicker, more dimensional product with superior durability, wind resistance, and a more aesthetically pleasing, textured appearance. 3-tab shingles are single-layer, flatter, and generally offer less protection and a shorter lifespan.

Q: How do these shingles contribute to energy efficiency?

A: While traditional black shingles absorb heat, "Cool Roof" rated asphalt shingles architectural incorporate highly reflective granules that deflect solar radiation. This reduces attic temperatures and, consequently, the load on HVAC systems, leading to energy savings, especially in warmer climates. They often meet or exceed Title 24 cool roof requirements.

Q: What kind of maintenance do laminated shingles require?

A: Laminated roof shingles are designed for low maintenance. Regular inspections (annual or bi-annual) are recommended to check for debris, damaged flashing, or any unusual wear. Shingles with algae-resistant granules significantly reduce the need for cleaning to remove unsightly streaks. Timely repair of any damage is crucial to maintain the roof's integrity and warranty.

Q: Are laminated shingles recyclable?

A: Yes, in many regions, asphalt shingles, including laminate roofing, can be recycled. Shingle tear-offs are increasingly being processed into asphalt pavement for roads, reducing landfill waste and conserving natural resources. Check with local recycling centers or your roofing contractor for availability in your area.

Logistics & Support: Lead Time, Warranty, and Customer Service

Lead Time and Fulfillment

Our commitment to efficient supply chain management ensures timely delivery for B2B projects. Standard product orders for asphalt shingles architectural typically have a lead time of 2-4 weeks, depending on volume and specific product lines. For large-scale or customized orders, lead times may extend to 6-8 weeks. We maintain strategic warehousing to facilitate rapid fulfillment for common product specifications. Expedited shipping options are available upon request and project feasibility assessment.

Comprehensive Warranty Commitments

Our laminated shingles shingles are backed by robust warranty programs, reflecting our confidence in product quality and longevity. All architectural shingles come with a Limited Lifetime Warranty for residential applications and a 30-50 year prorated warranty for commercial installations, covering manufacturing defects. Additionally, a 10-25 year Algae Resistance Warranty is standard on most product lines. A 15-year wind warranty (up to 130 mph) is also included. Detailed warranty documents outlining specific terms, conditions, and coverage details are available upon request to ensure full transparency and trust for our B2B partners.

Dedicated Customer Support and Technical Assistance

We provide unparalleled customer support tailored for B2B clients, architects, and contractors. Our dedicated technical support team offers expert guidance on product selection, installation best practices, building code compliance, and custom project solutions. Support channels include:

- Direct Phone Lines: Available during business hours for immediate assistance.

- Email Support: For detailed inquiries and documentation exchange.

- Online Resource Portal: Access to technical data sheets, installation guides, CAD details, and specification documents.

- On-Site Technical Consultation: For complex projects, our field specialists can provide on-site support and training.

Our goal is to ensure a seamless experience from initial inquiry to project completion, cementing strong, long-term partnerships with our clients.

Authoritative References

- Asphalt Roofing Manufacturers Association (ARMA). "Roofing Materials Guide: Asphalt Shingles." Accessed [Current Year].

- ASTM International. "Standard Specification for Asphalt Shingles Made from Fiberglass (Glass Mat) Type (ASTM D3462)." Accessed [Current Year].

- Underwriters Laboratories (UL). "Tests for Fire Resistance of Roof Covering Materials (UL 790) and Impact Resistance of Roof Covering Materials (UL 2218)." Accessed [Current Year].

-

Spain Stone Coated Metal Roof Tile | Premium & Weather-Resistant

NewsAug.27,2025

-

Durable Roofing Granules for Sale | Restore & Protect Your Roof

NewsAug.26,2025

-

Mosaic Shingles: 3-Tab vs. Architectural Differences Guide

NewsAug.21,2025

-

Stone Coated Metal Roof Tile-Grouper Tile: Durable & Stylish Roofing

NewsAug.19,2025

-

Roman Stone Coated Metal Roof Tile: Durable & Elegant Roofing

NewsAug.18,2025