សីហា . 26, 2025 15:02 ត្រឡប់ទៅបញ្ជី

Architectural Asphalt Shingles: Integration of Practicality, Economy, And Aesthetics

Architectural asphalt roof, As a roofing material with a long history and wide application, it still occupies an important position in the field of modern architecture. With its excellent waterproof performance, relatively low cost, and constantly improving aesthetics, Architectural Asphalt Shingless play a key role in residential, commercial, and industrial buildings. This article will explore the characteristics, advantages, and applications of Architectural Asphalt Shingles in modern architectural design, and look forward to its future development trends.

The core advantage of Architectural Asphalt Shingles lies in its excellent waterproof performance

Asphalt itself has good hydrophobicity, which can effectively prevent rainwater from seeping into the interior of buildings and protect the structure from moisture and corrosion. Architectural asphalt roof shingles improved by modern technology, such as modified asphalt coiled materials, further improve their anti-aging, high temperature, low temperature and UV resistance capabilities by adding polymers and other materials, thus extending the service life of the roof. In addition, Architectural Asphalt Shingless typically adopt a multi-layer structure, achieving seamless connections through overlapping, hot melting, and other methods, further enhancing the reliability of their waterproof performance.

Cost effectiveness is another significant advantage of Architectural Asphalt Shingless

Compared to other roofing materials such as metal roofs and ceramic tile roofs, the raw material and construction costs of architectural asphalt shingles are relatively low. The production process of asphalt roll is relatively simple, with high output and easy large-scale production, thereby reducing raw material costs. At the same time, the construction technology of Architectural Asphalt Shingles is relatively mature, with high construction efficiency and reduced labor costs. For projects with limited budgets, Architectural Asphalt Shingles is undoubtedly an economical and practical choice.

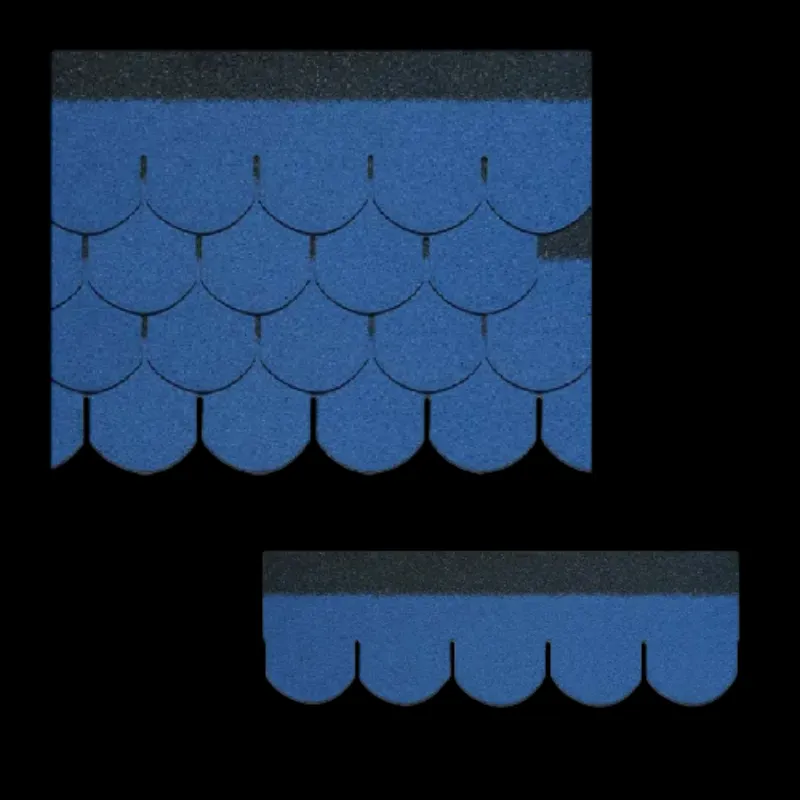

With the increasing importance of architectural aesthetics, Architectural Asphalt Shingless are gradually breaking away from their previous monotonous and rough image, and constantly innovating in design

New architectural composite shingles materials such as colored asphalt shingles and antique asphalt shingles have emerged, which give buildings a richer and more diverse appearance by changing the color, shape, and surface texture of asphalt. Modern Architectural Asphalt Shingless can even simulate the texture of traditional roofs such as stone slabs and wooden tiles, meeting people's pursuit of traditional architectural aesthetics. In addition, Architectural Asphalt Shingles can also be combined with other building materials, such as integrated with solar photovoltaic panels, to achieve diversified building functions and further enhance its application value.

Looking ahead to the future, with the continuous development of technology, Architectural Asphalt Shingless will also usher in more development opportunities

For example, developing more environmentally friendly and durable asphalt materials, adopting more intelligent construction techniques, improving the energy efficiency of architectural dimensional shingles, and so on. At the same time, in architectural design, Architectural Asphalt Shingles will also be combined with other green building technologies, such as rainwater harvesting systems and roof greening systems, to create a more sustainable and comfortable building environment.

In summary,architectural asphalt roof play an important role in modern architecture due to their excellent waterproof performance, relatively low cost, and constantly improving aesthetics. With the continuous advancement of technology and people's pursuit of architectural aesthetics, Architectural Asphalt Shingless will continue to leverage their unique advantages and make greater contributions to the development of the construction industry.

Architectural Asphalt Shingles FAQs

What is the core difference between Architectural Asphalt Shingles and traditional 3Tab tile?

Architectural Asphalt Shingles forms a three-dimensional contour by stacking multiple layers of asphalt substrates (usually 23 layers), which has the following advantages compared to a single-layer flat 3Tab tile:

Structural strength improvement: Unit area weight increased by 3050% (typical value: 240400 pounds per square meter), wind resistance performance can reach 130mph (UL 2218 Class F)

Visual layering: imitates the shadow effect of natural stone slabs or wooden tiles, commonly designed with random cuts

Durability difference: Using a higher proportion of modified asphalt (such as SBS polymer) results in better thermoplasticity than ordinary oxidized asphalt

Why is the lifespan of Architectural Asphalt Shingles claimed to be up to 30 years, but early failure often occurs in actual use?

Early failures are often caused by the following technical blind spots:

Insufficient ventilation: When the temperature in the attic exceeds 65 ℃, the softening of asphalt accelerates (the aging rate doubles for every 10 ℃ increase)

Adhesive strip failure: Failure to activate self-adhesive due to low temperature installation (<10 ℃) or dust pollution

Grassroots defect: When the moisture content of OSB board is greater than 18%, it causes mold growth on the back of tiles (ASTM D4442 testing standard)

Case data: NRCA statistics show that the median actual lifespan of correctly installed Architectural Asphalt Shingless in temperate climates is 28 years

How to optimize the anti icing performance of Architectural Asphalt Shingless in high-altitude regions?

A system solution is required:

Material level: Extend the designated Ice&Water Shield to the interior wall line+24 "(IRC R905.1.1 requirement)

Structural level: Install heating cables (rated power 1215W/ft) and temperature linkage control at the eaves

Thermal aspect: Ensure that the R value of the attic is ≥ 49 (7 zone climate, IRC N1102 standard) and set up continuous soffitridge ventilation

Monitoring indicator: The temperature difference between the edge and center of the roof in winter should be less than 5 ℉ (detected by infrared thermal imaging)

How has the algal resistance technology of Architectural Asphalt Shingles evolved?

The industry has developed three generations of protective technologies:

Generation 1 (before 2000): Surface copper particles (loss type) with an effective period of approximately 810 years

Generation 2 (after 2010): Zinc ion implantation into asphalt layer (such as CertainTeed's StreakFighter) ®), Extend lifespan to 15 years

3rd generation (2020+): Photocatalytic titanium dioxide coating (such as GAF's WeatherBlocker) ™), Activate and decompose organic matter through ultraviolet radiation

Test standard: ASTM D7869 Accelerated Algae Growth Test requires 3000 hours of salt spray exposure

Why do some Architectural Asphalt Shingless exhibit "edge warping" phenomenon under strong winds?

This issue involves the intersection of fluid mechanics and materials science:

Root cause: Corner Vortex forms local negative pressure, with a peak of up to 90 psf (ASCE 716 wind pressure calculation)

Material factor: The elastic modulus of SBS modified asphalt decreases by 40% at low temperatures (<20 ℃) (ASTM D5323 test data)

Solution:

The tile size optimized by wind tunnel during the design phase (recommended aspect ratio of 1.8:1)

Use wind lock adhesive tape (such as Henry's 208HS) instead of traditional heat activated adhesive tape during construction

Key reinforcement of the surrounding area of the roof (6 nails/piece+edge sealant)

-

The Importance of Bird Stop for Metal Roofing

ព័ត៌មានAug.26,2025

-

Roofing Granule: Composition, Function, and Application

ព័ត៌មានAug.26,2025

-

Granular Roll Roofing: Diverse Application Scenarios and Values

ព័ត៌មានAug.26,2025

-

Asphalt Shingles: a Long-Lasting Roofing Material

ព័ត៌មានAug.26,2025

-

Aluma Tile Metal Roofing: Excellent Performance and Aesthetic Value Coexist

ព័ត៌មានAug.26,2025