Там . 12, 2025 02:40 Back to list

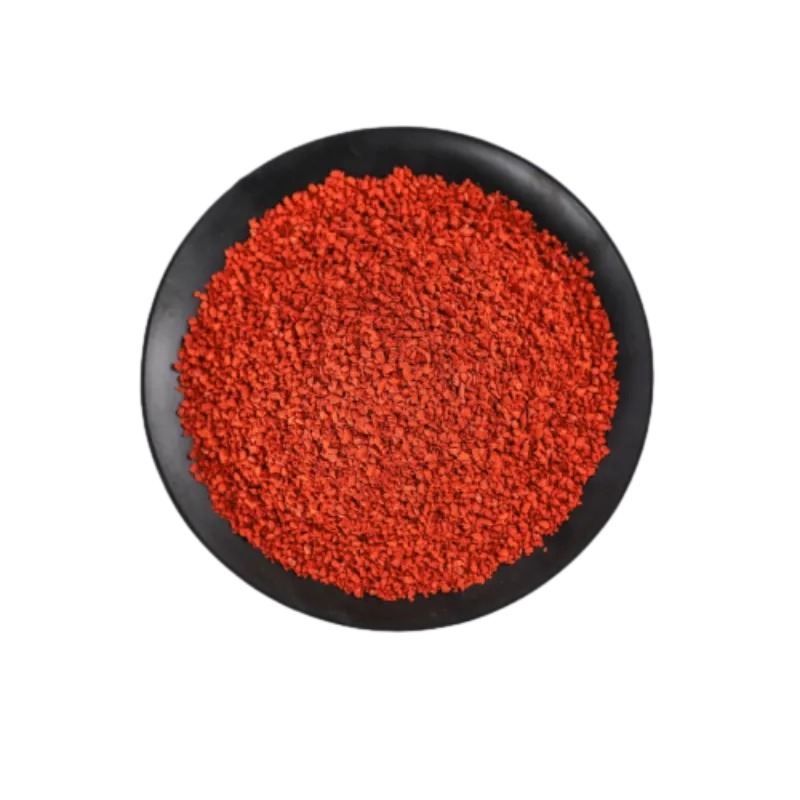

Premium Cooling Shingle Granules for Roof Protection

The Evolving Landscape of Granular Technology in Roofing

In the dynamic world of construction materials, shingle granules stand as a cornerstone component, pivotal to the durability, aesthetic appeal, and performance of asphalt shingles. These small, ceramic-coated mineral aggregates play a critical role beyond mere aesthetics, contributing significantly to a roof's UV protection, fire resistance, and overall longevity. As climate patterns shift and sustainability becomes a paramount concern, the demand for advanced granular solutions that offer superior reflective properties and extended lifespan is rapidly escalating. This push for innovation also addresses common issues such as roof shingles losing granules prematurely, a problem that compromises both the protective layer and the visual integrity of a roofing system.

The evolution of roofing materials has seen substantial progress, particularly in developing granules that enhance thermal reflectivity. This is crucial not only for traditional shingles but also for specialized applications like a metal roof with granules, where heat management is essential for energy efficiency. High-performance granules are engineered to meet stringent industry standards, ensuring they withstand harsh environmental conditions, from extreme UV radiation to freeze-thaw cycles. Our focus at Cool Roof Materials is on pioneering solutions like Red Granules HIREFLE, designed to push the boundaries of energy efficiency and material resilience, ensuring unparalleled protection and long-term value for diverse roofing projects.

The integration of specialized coatings and advanced processing techniques allows for the creation of granules that offer superior adhesion and color stability, mitigating the common issue of granule loss. This technological advancement translates directly into extended roof lifespans and reduced maintenance costs for property owners and commercial enterprises alike, reinforcing the crucial role of quality materials in long-term infrastructure integrity.

Fig 1. High-quality shingle granules for enhanced roof durability.

The Precision Engineering of Shingle Granules: A Detailed Manufacturing Process

The manufacturing of high-performance shingle granules is a sophisticated multi-stage process, meticulously engineered to ensure consistent quality and optimal functional properties. It begins with the selection of high-grade natural mineral rocks, typically basalt, slate, or rhyolite, chosen for their inherent hardness, density, and chemical inertness. These raw materials are sourced from quarries adhering to strict environmental and quality control protocols. The initial phase involves crushing the raw rock into precise particle sizes. Unlike casting or forging, which are relevant for metal components, granule production relies on advanced crushing, milling, and sieving techniques to achieve uniform particle distribution, critical for consistent shingle performance and preventing issues like premature roof shingles losing granules.

Following size reduction, the mineral particles undergo a stringent cleaning process to remove any impurities. The core of the granule's functionality comes from its ceramic coating. This involves applying a proprietary inorganic pigment slurry to the heated mineral particles in rotary kilns. The high-temperature ceramic firing process (calcination), typically exceeding 700°C (1292°F), permanently fuses the pigment to the mineral core, creating a durable, colorfast, and UV-resistant surface. This process is essential for achieving the reflective properties found in products like Red Granules HIREFLE, which significantly reduce heat absorption, contributing to energy savings.

Quality assurance is integrated throughout the entire manufacturing chain. Each batch of shingle granules is subjected to rigorous testing against international standards such as ISO 9001 for quality management and ASTM standards for granule adhesion, UV resistance (ASTM D3462), and color stability. Specialized optical sorters and sieving systems ensure uniform particle size and remove any foreign matter. This meticulous approach guarantees a projected service life exceeding 25-30 years for shingles incorporating these advanced granules, depending on environmental conditions and shingle specifications.

These superior granules find wide application across various industries beyond conventional residential roofing. In industrial sectors such as petrochemical complexes, metallurgy facilities, and water treatment plants, where roofing integrity against harsh elements is paramount, granules provide essential fire resistance and surface protection. For instance, the use of highly reflective shingle granules on a commercial facility's roof can significantly reduce internal cooling loads, offering substantial energy savings. The inherent anti-corrosive properties and exceptional durability make them an ideal choice for roofs exposed to industrial pollutants or extreme weather conditions.

Fig 2. Advanced reflective shingle granules for superior thermal performance.

Technical Specifications and Performance Metrics

Understanding the technical parameters of shingle granules is crucial for specifiers and contractors aiming to optimize roof performance. Key metrics include solar reflectance index (SRI), emissivity, particle size distribution, specific gravity, and UV degradation resistance. For instance, a higher SRI value indicates greater ability to reflect solar heat, directly contributing to cooler indoor temperatures and reduced air conditioning costs. Emissivity measures a material's ability to radiate absorbed heat. These properties are particularly important for cool roof applications, aligning with building codes focused on energy efficiency.

| Parameter | Unit/Standard | Typical Value Range | Benefit/Significance |

|---|---|---|---|

| Solar Reflectance Index (SRI) | ASTM E1980 | >70 (for light colors), >25 (for dark colors) | Reduces heat absorption, lowers cooling costs. |

| Thermal Emissivity | ASTM C1371 | >0.85 | Efficiently radiates absorbed heat, aids cooling. |

| Particle Size (passing 10-mesh sieve) | ASTM D4586 | 98-100% | Ensures optimal adhesion and uniform coverage. |

| Specific Gravity | ASTM D7019 | 2.7 - 3.0 g/cm³ | Indicates material density and durability. |

| UV Degradation Resistance | ASTM G154 (Accelerated Weathering) | No significant color fade or structural degradation after 5000 hrs. | Maintains aesthetic and protective qualities over time. |

| Adhesion (Granule Retention) | ASTM D3462 (Post-Aging) | Minimum 95% retention | Prevents premature granule loss, extends shingle life. |

Our Red Granules HIREFLE product line exemplifies these advanced characteristics, offering superior solar reflectivity and thermal emissivity crucial for reducing urban heat island effect and lowering energy consumption in buildings. The robust ceramic coating ensures exceptional color retention and resistance to weathering, addressing concerns about roof shingles losing granules due to environmental exposure. This focus on performance metrics empowers our clients to make informed decisions, ensuring the selection of materials that deliver measurable long-term benefits and comply with stringent building efficiency standards.

Beyond Conventional Roofing: Specialized Applications and Energy Solutions

While primarily known for asphalt shingles, the applications of advanced shingle granules extend into specialized energy-saving solutions. One significant area is the development of cool roof technologies, which utilize highly reflective granules to reduce surface temperatures. This principle is particularly effective when applied as a cooling paint for asbestos roof sheets, offering a dual benefit of encapsulating hazardous asbestos fibers while simultaneously providing a highly reflective, energy-efficient surface. Such applications are critical for aging industrial and commercial buildings seeking cost-effective upgrades to meet modern energy efficiency standards.

Our expertise includes developing customized granular solutions that integrate seamlessly with various roofing materials and systems. For projects involving the remediation of existing structures, such as those with asbestos roofing, our specially formulated granules can be incorporated into protective coatings. This not only provides a safe encapsulation layer but also transforms the roof into an active thermal barrier. The reflective properties of the granules within the asbestos sheet cooling paint significantly decrease the roof's heat absorption, leading to cooler internal environments and substantial reductions in air conditioning load, particularly in hot climates.

Client feedback consistently highlights the tangible benefits of our high-SRI granules. A recent case study involving a large manufacturing facility in Arizona saw a measured decrease of roof surface temperature by up to 25°C (45°F) during peak summer hours after applying a granular-infused coating. This translated into a documented 18% reduction in HVAC energy consumption. Such empirical data underscores the experience and authoritative performance of our granular products in real-world scenarios, making them a trusted choice for demanding industrial and commercial applications. We collaborate closely with engineers and contractors to provide tailored solutions, ensuring optimal performance for unique project requirements.

Fig 3. Diverse applications of shingle granules in modern roofing systems.

Ensuring Trust: Quality Assurance, Support, and Custom Solutions

At Cool Roof Materials, our commitment to trust and reliability is paramount. We adhere to the highest international quality standards, including ISO 9001 and ISO 14001, ensuring that every batch of advanced granules meets rigorous performance and environmental criteria. Our long-standing partnerships with leading roofing manufacturers and our over 20 years of service in the industry are testaments to our authoritative position and unwavering dedication to product excellence. We conduct extensive in-house and third-party testing, providing transparent data and certificates of analysis for all our products, including Red Granules HIREFLE. This ensures that our clients receive materials that are not only high-performing but also fully compliant with industry best practices.

We understand that each project presents unique challenges. Therefore, we offer bespoke customization services, from specific color matching to tailoring granular properties for unique climatic demands or specialized applications like cooling paint for asbestos roof sheets. Our technical support team, comprising experienced material scientists and roofing specialists, is available to assist clients from initial consultation through to project completion, offering expert advice on product selection, application techniques, and compliance. Our aim is to provide comprehensive solutions that meet precise project specifications and exceed performance expectations.

Fig 4. Custom shingle granules solutions for diverse project needs.

Frequently Asked Questions (FAQ)

- Q1: What distinguishes Red Granules HIREFLE from standard roofing granules?

- A1: Red Granules HIREFLE are engineered with advanced ceramic coatings to provide significantly higher solar reflectivity and thermal emissivity compared to standard granules. This results in superior cool roof performance, reducing heat absorption and contributing to lower indoor temperatures and energy costs. They also boast enhanced UV and color stability, minimizing the likelihood of roof shingles losing granules prematurely.

- Q2: Can these granules be used in coatings for a metal roof with granules?

- A2: Absolutely. While primarily designed for asphalt shingles, the exceptional reflective properties of Red Granules HIREFLE make them ideal for incorporation into high-performance coatings for metal roofs. This application enhances the thermal performance of metal roofs, reducing their surface temperature and improving overall energy efficiency, particularly beneficial for large commercial and industrial structures.

- Q3: What is the typical delivery cycle for large orders?

- A3: Our standard delivery cycle for large orders typically ranges from 4 to 6 weeks, depending on order volume, customization requirements, and destination. We maintain robust logistics networks to ensure timely and efficient delivery worldwide. For urgent requirements, expedited shipping options can be discussed with our sales team to accommodate tighter project timelines.

- Q4: What warranty or guarantee is provided with Red Granules HIREFLE?

- A4: We offer a comprehensive product warranty guaranteeing performance against specific technical parameters, including solar reflectivity, color retention, and granule adhesion, for a period consistent with typical shingle warranties (e.g., 25-year limited warranty for manufacturing defects). Specific warranty details are provided with each order and are backed by our stringent quality control processes and extensive industry experience.

References and Further Reading

- ASTM International Standards on Roofing and Waterproofing.

- The Cool Roof Rating Council (CRRC) Product Directory and Research Findings.

- National Renewable Energy Laboratory (NREL) Publications on Building Energy Efficiency.

- ISO 9001:2015 Quality Management Systems – Requirements.

-

Spain Tile Stone Coated Metal Roofing: Durable & Elegant

NewsAug.11,2025

-

Roofing Granules for Sale | Restore Shingles, Boost Cooling

NewsAug.10,2025

-

Durable Milan Stone Coated Metal Roof Tile | Elegant Roofing Solution

NewsAug.09,2025

-

Mosaic Shingles: Style, Durability & Shingle Comparisons

NewsAug.08,2025

-

Explore Types of Roof Shingles: Durable Asphalt & More!

NewsAug.07,2025