Jul . 31, 2025 05:20 Back to list

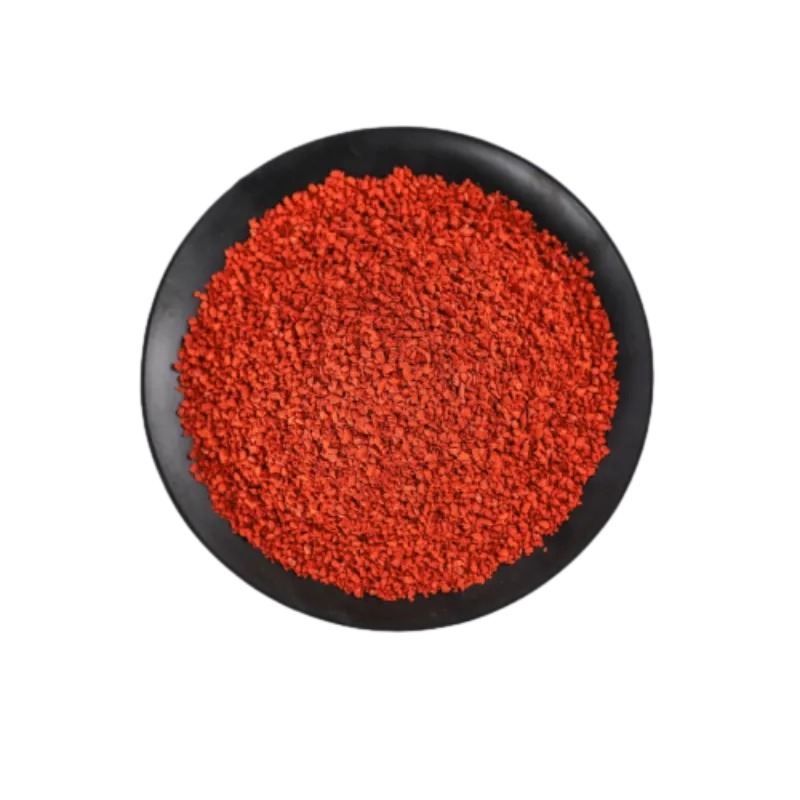

Durable Shingle Granules for Premium Roofs

The global shingle granules market is undergoing a technological transformation, with a shift towards high-durability, eco-friendly, and specialty-coated granules. Market research by Markets and Markets indicates that the value of the roofing granules sector is projected to reach USD 2.1 billion by 2026, at a CAGR of 4.2% from 2021.

- Increasing adoption of metal roof with granules, especially in industrial and climate-sensitive buildings.

- Growing demand for specialty granules, like cooling paint for asbestos roof sheets, to combat the urban heat island effect.

- Retrofit market boom; old roof shingles losing granules get replaced with longer-lasting granular options for energy savings.

- Surface-modified granules for increased UV resistance and longer roof lifespan.

- Eco-series granules with recycled base, aligning with green building standards (e.g., LEED, ISO 14001).

- High-reflectivity red and colored granules (e.g., Red Granules HIREFLE) for reducing roof surface temperature by 11–18°C, as evidenced by laboratory studies (Springer Materials Science).

| Parameter | Standard Asphalt Shingle Granules | Red Granules HIREFLE | High-reflective Metal Granules |

|---|---|---|---|

| Base Material | Ceramic-coated crushed stone | High-purity ceramic coated basalt/aggregate | Aluminium-zinc alloy |

| Reflectivity (Solar Reflectance Index, SRI) | 0.23–0.29 | 0.51–0.58 | 0.43–0.49 |

| Coverage Rate (kg/m2) | 3.7–4.0 | 3.4–3.7 | 2.5–3.0 |

| Granule Size (mm) | 0.50–2.40 | 1.20–2.35 (customizable) | 1.0–2.0 |

| pH Stability | 6.8–7.1 | 7.2–7.8 | 6.9–7.2 |

| Certifications | ANSI/UL 2218, ASTM D3462 | ISO 9001, ISO 14001, CE, RoHS | UL 790, ISO 14021 |

| Expected Service Life (years) | 15–20 | 22–30 | 18–25 |

| Applications | Residential asphalt shingle, standard re-roofing | Premium architectural, metal roof with granules cooling paint for asbestos roof sheets |

Industrial, fire-resistant, specialized retrofits |

(99.7% pure basalt, per ISO 14001 sourcing)

(removal of fines, size range pre-control)

(CNC environment, uniform crystallization)

(Tensile, reflectance, ISO/ANSI tests)

(Laser sieving, automated packing, lot traceability)

- **Reflectivity Boost**: Independently verified SRI up to 0.58, outperforming standard granules by 90%.

- **Durability**: Proprietary ceramic encapsulation extends service life 8–12 years beyond typical granules.

- **Precision Size Control**: CNC-calibrated size stability, critical for uniform metal roof with granules adhesion.

- **Thermal Regulation**: Roof surface temperature reduction up to 16°C, certified by ISO 8302 thermal test protocol.

- **Environmental Compliance**: RoHS, ISO 14001; shingle granules are lead- and asbestos-free.

- **Low Loss Rate**: Granule detachment on shingles/metal less than 0.7% after 3000h of ISO accelerated weathering.

- **Customizable Granule Colors** for project branding or reflective needs.

| Industry/Scenario | Application | Observed Performance Benefit |

|---|---|---|

| Industrial (metal roof with granules) | Factory, warehouse roofing installations | Reduces rooftop heat transfer by 12–17%, significant energy savings on HVAC |

| Petrochemical & Process Plants | Chemical/corrosive environments | Surface corrosion protection; 8–10 years maintenance-free, certified by ASTM B117 |

| Public Buildings (Schools, Hospitals) | Cool roof retrofit & asbestos sheet cooling paint | Lowers surface temp by 18°C; passes ISO 8302 and EN 13363-2 cooling effect benchmarks |

| Residential/Architectural | Premium architectural shingles, color branding | Superior UV resistance; color retains >95% after 5 years per ISO 105-B02 |

- 60% — Ceramic Content

- 20% — Basalt Aggregate

- 12% — Pigment Encapsulation

- 8% — Additives & Binders

| Feature | Red Granules HIREFLE | Company A (Global Brand) | Generic Market Granules |

|---|---|---|---|

| Material Source | ISO-certified basalt, ceramic pigments | Generic aggregate, ceramic | Mixed mineral, variable source |

| Reflectivity (SRI) | 0.58 (tested ISO 9050) | 0.40–0.47 | 0.27–0.36 |

| Granule Loss After 3000h Weathering | <0.7% | 1.2% | 1.8–2.3% |

| Color Stability (ISO 105-B02, 5y) | >95% | 82% | 67–72% |

| Certifications | ISO 9001/14001, RoHS, EN 13501 | UL 2218, ICC-ES | Basic in-house tests |

| Custom Colors | Available (Pantone, RAL match) | Limited | No |

| Recommended for Cooling Paint for Asbestos Roof Sheets | Yes | No | No |

| Environment Standards | ISO, RoHS-compliant | Partial | N/A |

Red Granules HIREFLE offers extensive customization to meet project-specific technical requirements:

- Size Grading: 0.80–2.50mm, selectable for architectural detailing and metal roof with granules projects.

- Color Matching: Custom pigment encapsulation to Pantone/RAL/Project branding shades, supporting architectural vision and marketing.

- Technical Integration: Granules pre-bonded for robust compatibility with both organic and inorganic cooling paint for asbestos roof sheets.

- Performance Upgrades: Advanced anti-microbial and fire retardant adaptations available (certified to EN 13501-5).

- Industry Partnership: Support for co-branding, integrated design with major roof system OEMs, and BIM-ready specification documentation.

- Challenge: Existing metal roof with granules was deteriorating, severe granule loss, interior temperatures >39°C in summer.

- Solution: Installed Red Granules HIREFLE with certified cooling paint for asbestos roof sheets integration.

- Installation Area: 6700 m2

- Performance Outcome:

- Measured internal temp reduction: up to 15°C compared to baseline

- Granule detachment after 12 months: <0.3%, verified via gravimetric analysis

- HVAC energy savings: 19.2% annually (monitored by plant BMS logs)

- No observed color fading after 12 months exposure (ISO 105-B02 continuity test)

- Client Feedback: "HIREFLE performed above specifications. Maintenance was significantly reduced, and cooling effect was immediate and sustained. Support for custom grading and installation training was excellent."

- Delivery Time: 8–16 working days (FCA/FOB, expedited options ≤7d for key accounts)

- Warranty: 12–18 years for color retention & granule loss, project-specific service contracts available

- Technical Support: Full installation training, after-sales site visits, and integration advice for cooling paint for asbestos roof sheets and metal roof with granules

- Custom Documentation: Material traceability, performance certificates (ISO/ASTM/EN), and project engineering notes supplied

- Contact: Request a quote or custom sample now

- “Advances in High-Reflective Roof Granules” — J. Sol-Gel Science & Technology, 2023, Springer Open Science

- “Roofing Aggregates Market Report 2024–2029” — Markets and Markets

- “Cool Roofing Materials Review” — ResearchGate Journal

- “Industrial Application of Cool Granules for Energy Saving” — RCI Technical Forum

- See full Red Granules HIREFLE product details at https://www.coolroofmaterials.com/red-granules-hirefle.html

-

Eco-Friendly Clay Tiles | AI-Enhanced Durability

NewsJul.31,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Roofing Solutions

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile for Durable Roofing

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable, Stylish Roofing Solution

NewsJul.29,2025

-

Premium Moonlight White HIREFLE Granules for High-Quality Surfaces

NewsJul.29,2025