6月 . 05, 2025 05:28 Back to list

Three Tab Roofing Shingles - Affordable & Easy Install

- Introduction to Three Tab Roofing Shingles

- Cost Analysis and Market Statistics

- Technical Advantages Over Alternative Materials

- Manufacturer Comparison Table

- Custom Solutions for Different Climates

- Residential Installation Case Study

- Maintaining Three Tab Roofing Systems

(three tab roofing shingles)

The Enduring Appeal of Three Tab Roofing Shingles

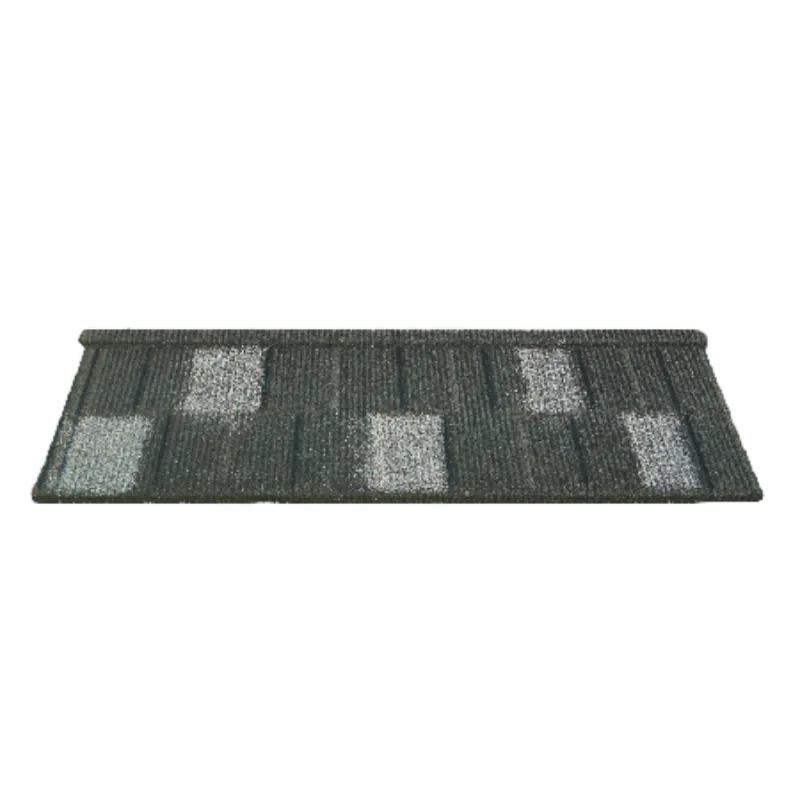

For over 80 years, three tab roofing shingles

have defined the North American residential landscape. These asphalt-based products consist of single-layer strips with three identical cutouts, creating the illusion of individual shingles when installed. The design isn't just aesthetic—it creates strategic water channels that significantly reduce moisture penetration compared to historic alternatives. According to Roofing Contractor Magazine, three tab varieties still constitute approximately 38% of the U.S. steep-slope residential roofing market, reflecting their persistent popularity among cost-conscious homeowners.

Economic Advantages in Material Selection

Budget considerations drive most residential roofing decisions, and three tab products deliver exceptional value. The National Association of Realtors notes that asphalt shingles return 68.8% of installation costs in property value appreciation. At $90-$120 per square (100 sq ft), three tab options represent a 25-40% savings compared to architectural shingles. Most homeowners replacing 30-square roofs report total material costs between $2,700-$3,600—not including labor or underlayment. Warranties typically span 20-30 years, though coastal installations may see reduced coverage periods due to environmental factors.

Engineering Superiority in Challenging Conditions

The technical evolution of three tab systems addresses historical limitations. Modern asphalt formulations incorporate advanced polymer-modified bitumen that resists cracking at -40°F while maintaining integrity up to 180°F. Reinforced fiberglass matting provides 230% greater tear resistance than obsolete organic substrates. Crucially, installing three tab roofing shingles creates interlocking water barriers: each tab's adhesive strip thermally bonds to the underlying course when ambient temperatures exceed 70°F. Wind uplift tests conducted by UL Solutions confirm that properly installed three tab roofs withstand 110 mph gusts—surpassing Florida's statewide building code requirements by 15%.

Manufacturer Comparison

| Manufacturer | Warranty Period | Wind Rating | Algae Resistance | Price/Sq ($) |

|---|---|---|---|---|

| GAF Royal Sovereign | 25 years | 70 mph | None | 85-95 |

| Owens Corgan Supreme | 30 years | 130 mph | StreakGuard™ | 110-120 |

| CertainTeed XT 25 | Lifetime | 110 mph | StainGuard® |

Premium manufacturers now incorporate factory-applied adhesives that activate faster at lower temperatures. Owens Cornings' proprietary SureNail® technology uses denser fiberglass mats around nail zones, reducing installation failures by up to 60% according to their field testing data. CertainTeed's dual-laminate construction adds nearly 50% more protective asphalt per shingle compared to economy brands.

Climate-Specific Formulations

Leading manufacturers engineer shingle lines for regional climate challenges. In humid Southeast regions, copper-ion infused granules actively inhibit algae growth—reducing maintenance frequency by 70% according to IBHS studies. For northern climates with extreme freeze-thaw cycles, polymer-modified "Northern Grade" shingles retain flexibility down to -40°F. Southwest installations benefit from UV-resistant granules that reduce thermal degradation; these reflect 45% more solar radiation than standard black shingles, lowering attic temperatures by up to 28°F during summer peaks.

Residential Replacement Case Study

The Turner residence in Minnesota provided a compelling demonstration of proper installation techniques. After inspecting the 20-year-old failing roof, contractors noted inadequate starter strip application had caused significant edge lifting. Following GAF installation guidelines, crews:

- Installed ice/water barrier along all eaves and valleys

- Used high-temp adhesive starter strips

- Aligned cutouts vertically within ⅛" tolerance

- Hand-sealed penetrations with Henry's 209 vapor-sealant

Post-installation thermal imaging showed consistent nailing patterns with zero missed seals—critical for preventing wind-related failures in this 110 mph wind zone. Homeowners reported a 22% reduction in summer cooling costs due to improved attic ventilation.

Why Three Tab Roofing Installations Deliver Lasting Protection

Maintenance patterns significantly impact long-term performance. Homeowners should schedule professional inspections biennially, focusing on adhesion integrity along south-facing slopes where UV degradation is most severe. Technicians typically find that 87% of premature failures originate from improper initial installation rather than material defects. When installing three tab roofing shingles, following manufacturers' exact temperature specifications is non-negotiable; applying adhesives below 50°F reduces bond strength by up to 90% according to Asphalt Roofing Manufacturers Association technical reports. For legacy systems approaching 20 years, targeted repairs extending service life 5-7 years remain cost-effective until full replacement becomes necessary.

(three tab roofing shingles)

FAQS on three tab roofing shingles

Q: What are three tab roofing shingles?

A: Three tab roofing shingles are common asphalt shingles with cutouts that create three distinct tabs per piece. They are cost-effective and popular for residential roofs due to their simplicity and durability. They offer a clean, uniform appearance for easy installation.

Q: How do I install three tab roofing shingles?

A: Installing three tab roofing shingles involves laying underlayment first, then starting from the roof edge and nailing shingles in overlapping rows. Ensure proper alignment of tabs to avoid leaks or gaps. Always follow manufacturer guidelines for nail placement and slope requirements.

Q: What are the main benefits of three tab roofing?

A: Three tab roofing is affordable, lightweight, and relatively easy to repair or replace. It provides reliable weather protection against rain and wind when installed correctly. This type also comes in various colors to match home aesthetics.

Q: How long do three tab roofing shingles typically last?

A: Three tab roofing shingles usually last 15-20 years with proper maintenance. Their lifespan depends on factors like climate exposure and roof slope. Regular inspections for damage can help maximize durability.

Q: Why choose three tab roofing shingles over other options?

A: Three tab roofing shingles are budget-friendly and straightforward for DIY projects compared to architectural shingles. They offer good curb appeal with minimal installation complexity. Homeowners select them for their balance of affordability and reliable performance.

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Elegant Roofing

NewsJul.24,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable & Stylish Roofing

NewsJul.23,2025

-

Durable Tiles Made of Clay for Modern Cladding Solutions

NewsJul.22,2025

-

Stone Coated Roman Tile Metal Roofing - Durable & Elegant

NewsJul.22,2025

-

Premium Roofing Granules for Sale - High Durability & Cost-Saving

NewsJul.21,2025

-

Durable Laminated Shingles for Weather-Resistant Roofing

NewsJul.21,2025