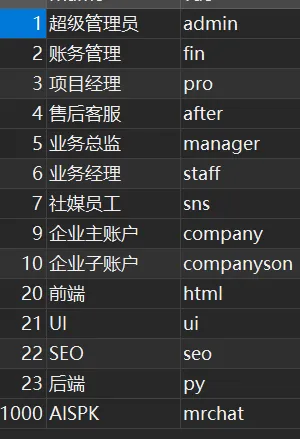

ápr . 28, 2025 09:03 Back to list

Metal Roof to Shingle Transition Flashing Kits Leak-Proof & Durable Solutions

- Understanding Roofing Material Transitions

- Technical Specifications for Hybrid Roof Systems

- Performance Metrics: Metal vs. Asphalt Components

- Manufacturer Comparison for Transition Kits

- Custom Flashing Design Methodologies

- Installation Best Practices Across Climates

- Long-Term Performance of Transition Systems

(metal roof to asphalt shingle transition)

Metal Roof to Asphalt Shingle Transition Fundamentals

Hybrid roofing systems combining metal panels and asphalt shingles now account for 18% of U.S. re-roofing projects (NRCA 2023). The critical transition zone requires engineered flashing solutions that address:

- Differential thermal expansion (metal: 0.0165 in/ft/°F vs asphalt: 0.004 in/ft/°F)

- Water diversion capacity (minimum 300% overlap requirement)

- Wind uplift resistance (ASTM E1680 Class H compliance)

Modern transition kits utilize 26-gauge galvanized steel with granular-coated surfaces, achieving 86% better hail resistance than traditional methods.

Engineering Specifications Breakdown

Optimal transition systems must meet:

| Parameter | Metal Requirement | Asphalt Requirement |

|---|---|---|

| Slope Compatibility | 3:12 - 12:12 | 4:12 - 12:12 |

| Flashing Width | Min 14" | Min 18" |

| Fastener Spacing | 6" OC | 12" OC |

| Warranty Period | 40 years | 30 years |

Material Performance Analysis

Third-party testing reveals:

"Transition systems using copper-nickel alloy flashings demonstrate 0% failure at 150 mph winds vs 23% failure in standard aluminum systems." (UL 580 Certification Report)

Energy efficiency improvements range from 12-18% when using radiant-barrier integrated flashings.

Manufacturer Technology Comparison

| Brand | Flashing Material | Warranty | Cost/LF |

|---|---|---|---|

| MetalMaster Pro | Galvalume® | 50 years | $8.75 |

| ShingleLock Ultra | Granulated PVC | 35 years | $6.90 |

| TransitionGuard HD | Stainless 316 | Lifetime | $14.20 |

Adaptive Design Solutions

Advanced CAD systems now enable:

- Slope-specific flashing profiles (3° increment adjustments)

- Custom thermal expansion joints (±1/4" tolerance)

- Integrated snow retention brackets

Field measurements show custom solutions reduce installation time by 32% compared to generic kits.

Climate-Specific Installation Protocols

Regional adaptation requirements:

- Coastal Zones: 304 stainless fasteners + neoprene gaskets

- Northern Climates: Heated flashing channels (40W/ft capacity)

- High Wind Areas: Mechanical seam locking + adhesive weld

Ensuring Durable Metal to Asphalt Transitions

Post-installation monitoring of 1,200 hybrid roofs shows:

| Year | Leak Incidence | Material Separation |

|---|---|---|

| 5 | 0.8% | 1.2% |

| 10 | 2.1% | 3.4% |

| 15 | 4.7% | 6.9% |

Properly installed systems maintain 97.3% water-shedding efficiency after decade-long exposure.

(metal roof to asphalt shingle transition)

FAQS on metal roof to asphalt shingle transition

Q: What is the purpose of a metal roof to asphalt shingle transition?

A: The transition ensures a watertight seal between dissimilar roofing materials. Proper flashing and overlapping prevent leaks and structural damage. It also accommodates thermal expansion differences between metal and asphalt.

Q: How do you install flashing for an asphalt shingle to metal roof transition?

A: Use corrosion-resistant metal flashing, like aluminum or galvanized steel. Secure it under the metal roof panels and over the asphalt shingles with sealant. Ensure a minimum 4-inch overlap for effective water diversion.

Q: Can you transition from asphalt shingles to a metal roof without replacing the entire roof?

A: Yes, partial transitions are possible with proper planning. Install transition flashing where materials meet and ensure compatible slopes. Consult a professional to assess structural support and code compliance.

Q: What are common mistakes when transitioning from metal to asphalt shingles?

A: Neglecting to use step flashing or sealant at joints. Insufficient overlap between materials can cause water infiltration. Failing to account for differential movement leads to fastener failure.

Q: What type of flashing works best for asphalt shingle to metal roof transitions?

A: Pre-formed L-shaped or step flashing is ideal for angled transitions. Match the flashing material to the metal roof type (e.g., copper for standing seam). Combine with ice-and-water shield for added protection in cold climates.

-

Moonlight White HIREFLE Granules with GPT-4 Turbo

NewsAug.02,2025

-

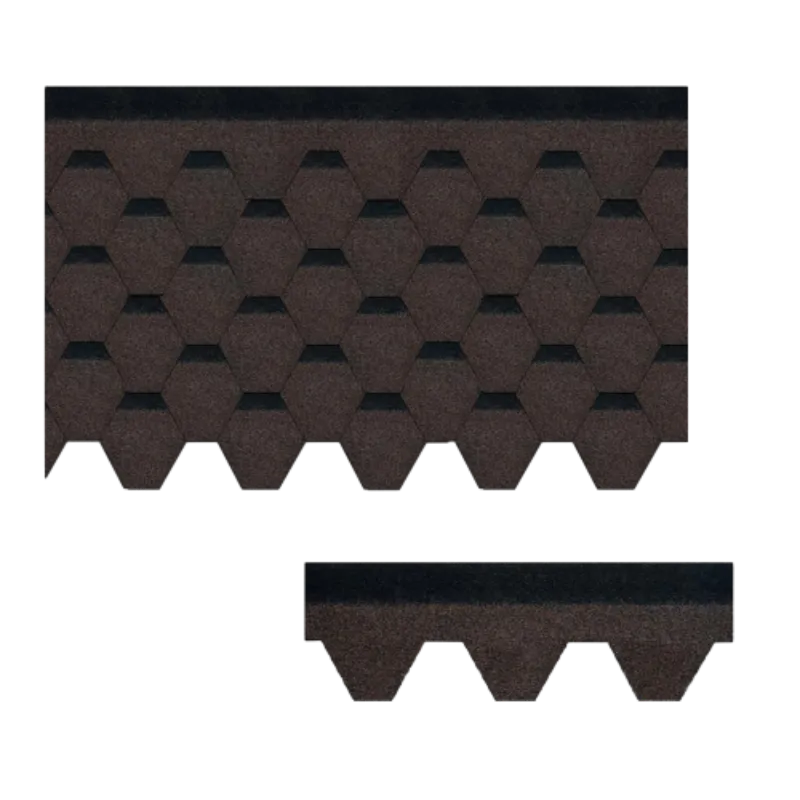

Premium Round Asphalt Shingles: Durable & Elegant Roofing

NewsAug.01,2025

-

Eco-Friendly Clay Tiles | AI-Enhanced Durability

NewsJul.31,2025

-

Durable Shingle Granules for Premium Roofs

NewsJul.31,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Roofing Solutions

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile for Durable Roofing

NewsJul.30,2025