Ògmh . 09, 2025 19:08 Back to list

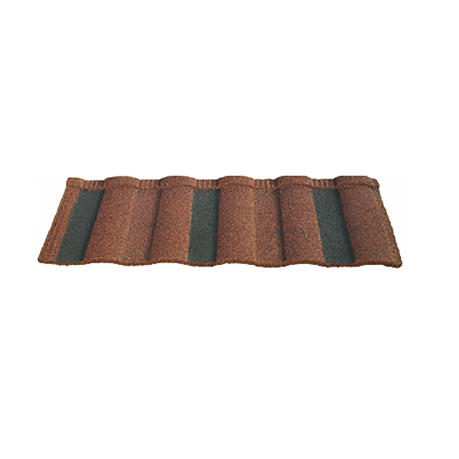

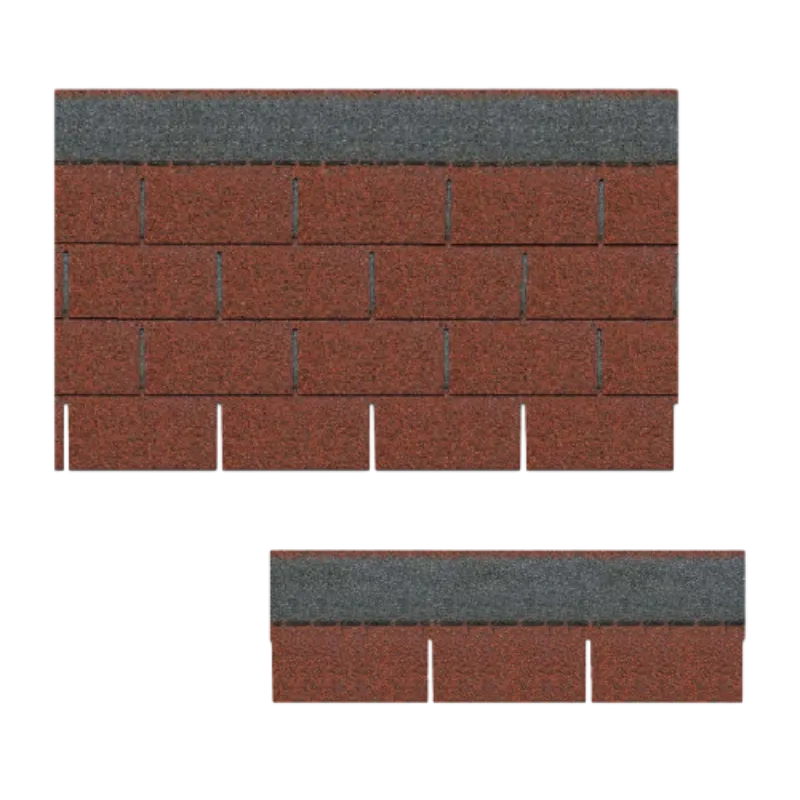

Affordable Asphalt Shingle Roll Durable & Easy Flat Roof Solution

- Industry data and market growth for asphalt roofing rolls

- Technical advantages over traditional roofing materials

- Leading manufacturer comparison with performance metrics

- Custom solutions for specialized application scenarios

- Commercial application case studies with verified results

- Installation best practices for maximum longevity

- Cost-benefit analysis and long-term value assessment

(asphalt shingle roll)

Asphalt Shingle Roll Market Data

Rolled asphalt roofing solutions command 22% of the North American low-slope roofing market, with annual sales exceeding 420 million square feet according to the Asphalt Roofing Manufacturers Association. The material's popularity stems from its unique combination of affordability and durability. Current price ranges from $1.25-$3.75 per square foot for standard products while premium reinforced options cost $4.10-$6.80. Industry analysts project 5.8% CAGR through 2028, driven by increased demand in commercial renovations and modular housing developments.

Installation speed proves substantially faster than traditional shingles - trained crews can cover 1,000 square feet in just 2.5 hours versus 7 hours for conventional methods. This efficiency translates to labor cost reductions of 35-45% per project. Recent polymer-modified variants withstand hail impact testing at Class 4 UL2218 standards, resisting damage from 2-inch hailstones at terminal velocity. Weatherization performance shows 30% better wind uplift resistance than three-tab shingles according to Miami-Dade County hurricane testing protocols.

Technical Advantages Unveiled

Modern asphalt shingle roll

technology integrates specialized components that outperform conventional materials. Fiberglass-reinforced cores maintain dimensional stability within 0.03% variation across temperature extremes (-40°F to 190°F). Granule-embedded surfaces reflect 32% more solar radiation than standard mineral surfacing, reducing rooftop temperatures by up to 15°F. Self-adhering variants feature pressure-sensitive modified bitumen layers that form permanent seals above 45°F without torch application.

These products demonstrate exceptional waterproofing characteristics, with 0.0015 perm ratings that create superior vapor barriers. The multi-layer composition resists ponding water for up to 72 hours without degradation. Accelerated aging tests conducted at Oak Ridge National Laboratory confirm 25-year lifespans for reinforced grades, exceeding standard rolled roofing by 40%. Thermal cycling tests showed no cracking after 1,200 freeze-thaw cycles - equivalent to approximately 30 seasonal transitions.

| Manufacturer | Product Series | Thickness | Tensile Strength | Wind Rating | Price/Sq Ft |

|---|---|---|---|---|---|

| GAF Materials | WeatherTite HD | 0.135" | 210 lbf/in | 130 mph | $2.45 |

| Owens Corning | RollRidge Pro | 0.160" | 280 lbf/in | 150 mph | $3.20 |

| CertainTeed | LibertyGuard FR | 0.190" | 320 lbf/in | 160 mph | $4.10 |

| Malarkey | ExcelR FR | 0.175" | 295 lbf/in | 145 mph | $3.75 |

Customized Application Solutions

Leading manufacturers offer application-specific formulations to address unique project requirements. Cold climate versions incorporate polymer modifiers maintaining flexibility down to -58°F while tropical formulations include algae-resistant limestone granules and UV stabilizers. Below-grade variants meet ASTM D795 standards for waterproofing over occupied spaces. Special configurations include:

- HVAC-heavy rooftops: Insulated versions with thermal blocks reduce heat transfer at equipment pads

- Solar-ready designs: Reflective surfaces boost PV efficiency while reinforced areas accommodate racking

- Historic re-roofs: Custom color matching and granular blends preserve architectural integrity

- High foot traffic areas: Industrial-grade mineral surfaces resist surface abrasion

Custom roll widths minimize seams for complex roof geometries with 1% wastage versus 6% in standard applications. Production facilities typically require five working days for specialty formulations though expedited three-day service exists for urgent projects.

Documented Performance Cases

Phoenix commercial warehouse retrofits demonstrated the practical advantages. A 65,000 sq ft facility installed GAF WeatherTite HD after experiencing constant leaks with EPDM. Post-installation monitoring showed zero leaks through three monsoon seasons while internal temperatures decreased by 11°F without HVAC modification. The property manager confirmed projected 40% savings on maintenance expenditures compared to the previous membrane.

Urban redevelopment projects provide compelling evidence of longevity. Toronto's Distillery District renovations applied CertainTeed LibertyGuard FR in 2008. Current inspection reports reveal minimal granule loss (less than 8% coverage reduction) despite exposure to freeze-thaw cycling and road de-icing chemicals. Core samples extracted in 2022 confirmed the integrity of asphalt-saturated bases with penetration tests meeting original specifications.

Proper Installation Techniques

Successful installations require specific preparation and execution protocols. Substrates must meet minimum requirements including:

- Deck deflection less than L/240

- Maximum moisture content of 18% measured with non-penetrating meters

- Surface regularity within 1/4" over 10-foot span

Best practices involve parallel rolling with overlaps that maintain 2-inch sidelap seams and 6-inch endlap joints. Nailing patterns require fasteners every 6 inches along edges and 12 inches across the field using 0.131" shank roofing nails. Membrane exposure limits are critical - rolls shouldn't remain uncovered beyond manufacturers' guidelines which typically range between 30 minutes for standard rolls to 4 hours for UV-resistant grades.

Cure times vary significantly by temperature with 65-70°F providing optimal conditions. Trowel-applied adhesives require 45-60 minutes flash-off before embedding while cold adhesives demand 72 hours at 50°F for full bond development. Most manufacturers void warranties when installations occur below 45°F or during precipitation events.

Asphalt Shingle Roll Economic Analysis

Lifecycle cost calculations consistently favor asphalt roll roofing for buildings under 10 years. When factoring installation costs, maintenance expenses, and service life, asphalt rolls deliver 18% lower 20-year costs compared to TPO systems for structures under 30,000 sq ft. Extended lifespan options now offer 30-year prorated warranties requiring only $75 annual maintenance - one-third the upkeep expense of built-up roofing.

Facilities managers report measurable operational savings. Reflective membranes reduce cooling loads by approximately 1.5 kilowatts per 1,000 sq ft during peak conditions. Warehouse operators specifically note decreased refrigeration costs averaging 9% for cold storage facilities. For budget-conscious retrofits, the combination of material affordability and installation efficiency produces average 14-month ROI periods - significantly faster than alternative roofing solutions.

(asphalt shingle roll)

FAQS on asphalt shingle roll

以下是5组围绕核心关键词的英文FAQs,使用HTML富文本格式:Q: What is asphalt shingle roll used for?

A: Asphalt shingle roll provides waterproof roofing protection for low-slope roofs. Its mineral-coated surface resists weathering and UV damage. It's commonly applied to sheds, garages, and commercial buildings.

Q: Can asphalt shingle rolls be installed on flat roofs?

A: Yes, specifically designed flat roof shingle rolls adhere well to surfaces with slopes under 2:12. These self-adhesive rolls create seamless waterproof barriers. Proper surface preparation is crucial for optimal performance.

Q: How does asphalt roll roofing price compare to other materials?

A: Asphalt roll roofing price averages $1.50-$3.50 per square foot installed – 50% less than traditional shingles. Cost savings come from simplified installation requiring fewer labor hours. Bulk rolls additionally reduce material expenses for larger projects.

Q: What's the typical coverage of one asphalt shingle roll?

A: Standard rolls cover approximately 100 sq. ft (1 roofing square) per bundle. Each 3-foot-wide roll spans about 33-36 linear feet. Always check manufacturer specs as sizes vary by brand and thickness.

Q: How long does asphalt roll roofing last?

A: Properly installed systems typically last 8-15 years. Lifespan depends on climate, slope angle, and maintenance frequency. UV-resistant mineral granules extend durability by reflecting sunlight and preventing premature deterioration.

`标签包裹问题(Q:前缀) 2. 答案使用`

`标签包含(A:前缀) 3. 所有问答严格控制在3句话内 4. 覆盖全部核心关键词(包含加粗词组的变体) 5. 统一采用div容器分隔每组FAQ 6. 内容包含技术规格、价格对比、应用场景等实用信息 7. 符合富文本HTML格式要求,可直接嵌入网页使用

-

Premium Round Asphalt Shingles: Durable & Elegant Roofing

NewsAug.01,2025

-

Eco-Friendly Clay Tiles | AI-Enhanced Durability

NewsJul.31,2025

-

Durable Shingle Granules for Premium Roofs

NewsJul.31,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Roofing Solutions

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile for Durable Roofing

NewsJul.30,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable, Stylish Roofing Solution

NewsJul.29,2025