Nov . 17, 2024 20:13 Back to list

cooling sheet manufacturing machine price

Understanding the Pricing of Cooling Sheet Manufacturing Machines

In the realm of industrial production, cooling sheets are pivotal components used in various applications, notably in packaging, electronics, and food preservation. As the demand for high-quality cooling solutions continues to grow, so does the need for efficient manufacturing machinery. This leads to an important question what factors influence the price of cooling sheet manufacturing machines?

1. Technology and Features

The price of cooling sheet manufacturing machines is significantly affected by the technology incorporated into the machine. Advanced machines equipped with high-tech features such as automated controls, enhanced production speed, and integrated quality monitoring systems typically carry a higher price tag. These technologies not only streamline the production process but also ensure the consistency and quality of the cooling sheets produced. For instance, machines with real-time monitoring capabilities can significantly reduce waste and improve efficiency, which may justify their higher initial cost.

Another critical factor in determining the price is the production capacity of the machine. Machines that can produce a higher volume of cooling sheets in a shorter amount of time often come at a premium. Manufacturers aiming to scale their production are generally willing to invest in larger machines that promise increased output and faster return on investment. Conversely, smaller machines catering to lower production demands usually come at a more affordable price point, appealing to businesses with limited space or lower sales volumes.

3. Material Compatibility

The materials that the machine can process also affect its pricing. Machines designed to work with a wider variety of materials or those that handle specialized materials—such as biodegradable or high-performance polymers—tend to be more expensive. This is due to the additional engineering and technology required to handle these materials effectively. Companies must assess their specific needs concerning material compatibility before investing in equipment, as this can significantly impact not only the initial purchase price but also long-term operational costs.

cooling sheet manufacturing machine price

4. Brand and Manufacturer

The manufacturer’s reputation and the brand behind the machine also play a crucial role in pricing. Established brands known for quality and reliability often charge more than newer or lesser-known manufacturers. When companies invest in higher-priced equipment from reputable brands, they often do so with the expectation of better service, reliability, and longer lifespan. Additionally, warranty and support services provided by reputable manufacturers can save companies considerable amounts on maintenance and potential downtime in the future.

5. Geographic Considerations

Geographic location and market conditions can also influence machine prices. In regions with a high demand for cooling sheet production machinery, prices may be inflated due to competitive market dynamics. Conversely, in areas with lower demand, prices may be more competitive. Import duties, shipping costs, and domestic taxes can further complicate matters. Companies need to consider these factors when importing machinery from different countries, which can add to the overall cost.

6. Second-hand vs. New Machines

Finally, the option between purchasing new or second-hand machines can significantly influence the cost. Second-hand machines can offer substantial savings but may come with hidden risks, such as potential maintenance issues or outdated technology. New machines, while more expensive, often come with the latest technology, warranties, and service contracts that can provide peace of mind.

Conclusion

In summary, the price of cooling sheet manufacturing machines is influenced by various interconnected factors including technology, production capacity, material compatibility, brand reputation, geographic conditions, and buying options. Businesses need to carefully assess their production needs, budget constraints, and long-term goals when choosing the right equipment. By thoroughly evaluating these factors, manufacturers can make informed decisions that align with their operational objectives and ensure the successful implementation of their cooling sheet production processes.

-

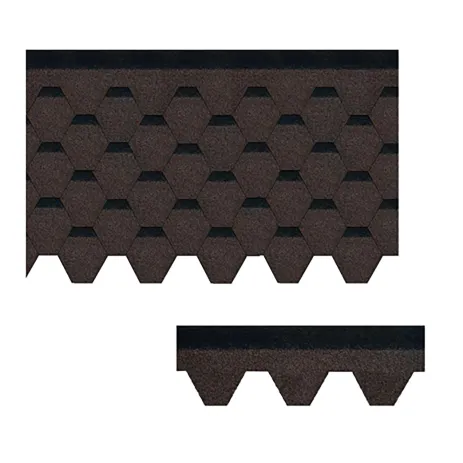

Mosaic Shingles: Durable Roofing, Compare 3 Tab vs Architectural Styles

NewsJul.25,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Elegant Roofing

NewsJul.24,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable & Stylish Roofing

NewsJul.23,2025

-

Durable Tiles Made of Clay for Modern Cladding Solutions

NewsJul.22,2025

-

Stone Coated Roman Tile Metal Roofing - Durable & Elegant

NewsJul.22,2025

-

Premium Roofing Granules for Sale - High Durability & Cost-Saving

NewsJul.21,2025