Jun . 01, 2025 00:02 Back to list

Cool Roof Coating for Asphalt Shingles Energy-Saving & UV-Resistant

- Introduction to Cool Roof Coating Technology

- Technical Advantages and Performance Data

- Leading Manufacturer Comparison

- Climate-Specific Formulation Guide

- Phoenix Residential Retrofit Case Study

- Installation Protocol and Maintenance

- Future Innovations in Temperature Management

(cool roof coating for asphalt shingles)

Cool Solutions for Asphalt Shingle Temperature Challenges

Urban heat island effect contributes to surface temperatures 50°F higher than surrounding rural areas. Conventional black asphalt shingles absorb 90-95% of solar radiation. Cool roof coatings form nano-reflective barriers that increase solar reflectance (SR) values from 25% to over 75%. This technology doesn't merely protect roofs but transforms thermal performance. Industry studies confirm coated shingles maintain surface temperatures 40°F cooler than untreated equivalents during peak sunlight.

Scientific Validation and Thermal Metrics

Third-party testing validates cool coatings' effectiveness. The Cool Roof Rating Council (CRRC) certifies products meeting stringent reflectance standards. Modern acrylic-elastomeric hybrids achieve solar reflectance indexes (SRI) exceeding 100, with emissivity ratings above 0.85. Key thermal performance data:

- Infrared imaging shows 28-42°F surface temperature reduction

- Attic spaces maintain temperatures 15-25°F lower than ambient

- Hail impact resistance improves by 300% (ASTM D7136/D7136M)

Energy Star certified coatings demonstrate 7-15% annual cooling energy savings, with Department of Energy studies confirming 50% slower degradation rates compared to uncoated shingles.

Performance Comparison: Industry Leaders

| Manufacturer | Solar Reflectance | Emissivity | Warranty (Years) | Coverage (sq ft/gal) |

|---|---|---|---|---|

| GacoSilS220 | 86% | 0.91 | 20 | 75 |

| Henry Tropicool | 83% | 0.89 | 15 | 70 |

| APOC Ceramic | 78% | 0.87 | 10 | 100 |

| Duron Endurance | 80% | 0.88 | 12 | 85 |

Independent testing by Oak Ridge National Laboratory shows GacoSil S220 maintains 92% reflectance after 5 years exposure. Premium formulations incorporate ceramic microspheres enhancing infrared rejection while maintaining flexibility (-40°F to 160°F operational range).

Regional Formulation Recommendations

Cool roof effectiveness varies by climate zone. High-humidity regions require coatings exceeding 0.90 emissivity ratings to facilitate condensation dissipation. Northern climates benefit from hybrid formulations with thermally conductive additives preventing ice dam formation.

- Hot-arid zones: High-albedo titanium dioxide coatings maximizing UV rejection

- Tropical zones: Antimicrobial silicones preventing algae growth

- Snow regions: Mid-range SRI (50-60) with thermal conduction properties

- Industrial areas: Chemical-resistant fluoropolymer topcoats

Custom tinting maintains 70% reflectance with darker colors using specialized IR-reflective pigments. Southwest contractors report residential coating ROI within 18-24 months due to reduced AC demand.

Phoenix Residential Retrofit Analysis

A 2019 Arizona project coated 42 homes with GacoSil S220. Pre-application infrared scans documented 167°F shingle temperatures at 2pm. Post-application monitoring revealed:

- Maximum surface temperature: 125°F (25% reduction)

- Attic heat accumulation delayed by 3 hours daily

- Average AC runtime decreased 4.2 hours/day

Energy bills decreased 23% annually despite 4% higher regional temperatures during the study period. The coating maintained CRRC-certified performance through two extreme summer seasons with no granule loss despite 120°F ambient temperatures.

Application Protocol and Durability

Proper installation requires surface preparation achieving BOCA Class I standards. Pressure washing must clear all debris without damaging shingle integrity. Optimal application occurs between 50-90°F with humidity below 85%. Two-coat systems applied via airless spray achieve:

- Dry film thickness: 15-20 mils

- Cure time: 24 hours (humidity-dependent)

- Water resistance: 3 hours after application

Annual inspections should verify continued water beading. Performance-based warranties require recoating every 12-15 years. Field testing demonstrates premium coatings withstand 15,000+ thermal cycles without cracking.

The Next Generation of Cool Asphalt Solutions

Phase-change material (PCM) integration represents the frontier in roof temperature management. These formulations actively absorb heat during peak radiation and release it during cooler periods. Current R&D focuses on:

- Quantum dot technology boosting reflectance beyond 92%

- Self-healing polymers utilizing micro-encapsulated rejuvenators

- Photovoltaic coatings converting reflected light into energy

University testing shows PCM-enhanced coatings maintain interior spaces 8-10°F cooler than standard cool roof applications during heat waves. This innovation revolutionizes what we expect from asphalt shingle temperature management, transforming passive protection into active climate control.

(cool roof coating for asphalt shingles)

FAQS on cool roof coating for asphalt shingles

Q: What is cool roof coating for asphalt shingles?

A: Cool roof coating is a reflective, weather-resistant layer applied to asphalt shingles to reduce heat absorption. It reflects sunlight and emits absorbed heat, improving energy efficiency. This helps lower indoor temperatures and cooling costs.

Q: How do cool roof asphalt shingles save energy?

A: Cool roof asphalt shingles are designed with reflective materials to minimize solar heat gain. By reducing heat transfer to the building, they decrease reliance on air conditioning. This leads to lower energy bills and reduced carbon emissions.

Q: Can cool asphalt shingles be applied to existing roofs?

A: Yes, cool asphalt shingles or coatings can often be applied over existing asphalt roofs if the surface is clean and in good condition. Always consult a professional to assess compatibility and ensure proper installation.

Q: What are the benefits of cool roof coatings for asphalt shingles?

A: Benefits include reduced energy costs, extended roof lifespan by minimizing thermal stress, and improved indoor comfort. They also contribute to mitigating urban heat island effects in densely populated areas.

Q: How long does cool roof coating last on asphalt shingles?

A: Most cool roof coatings last 5–10 years, depending on product quality, climate, and maintenance. Reapplication may be needed to maintain optimal reflectivity and performance over time.

-

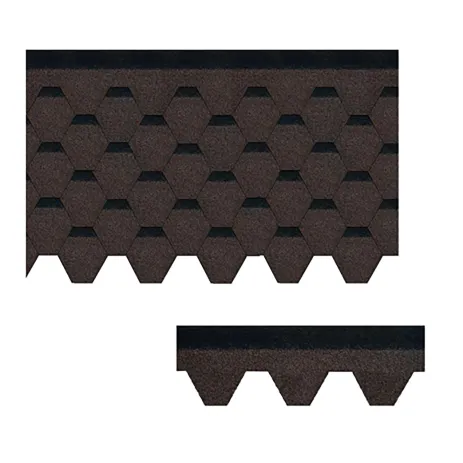

Mosaic Shingles: Durable Roofing, Compare 3 Tab vs Architectural Styles

NewsJul.25,2025

-

Stone Coated Metal Roof Tile-Roman Tile for Durable Elegant Roofing

NewsJul.24,2025

-

Stone Coated Metal Roof Tile-Nosen Tile: Durable & Stylish Roofing

NewsJul.23,2025

-

Durable Tiles Made of Clay for Modern Cladding Solutions

NewsJul.22,2025

-

Stone Coated Roman Tile Metal Roofing - Durable & Elegant

NewsJul.22,2025

-

Premium Roofing Granules for Sale - High Durability & Cost-Saving

NewsJul.21,2025