maj . 29, 2025 02:56 Back to list

Aluma Tile Metal Roofing Durable, Lightweight & Energy-Efficient

- Introduction to Modern Metal Roofing Solutions

- Technical Advantages of Aluma Tile Systems

- Performance Comparison: Leading Manufacturers

- Customization Options for Architectural Needs

- Case Studies: Residential & Commercial Applications

- Installation Best Practices & Maintenance

- Why Aluma Tile Outperforms Traditional Materials

(aluma tile metal roofing)

Aluma Tile Metal Roofing: Revolutionizing Building Envelopes

Contemporary construction demands materials combining 97% recyclability with 50-year lifespans. Aluma tile metal roofing systems meet these benchmarks through cold-rolled aluminum-zinc alloy substrates that achieve 0.25mm thickness precision. Unlike conventional asphalt shingles showing 34% efficiency loss after decade-long UV exposure, third-party testing confirms aluma tiles retain 98.2% reflectivity across 25-year cycles.

Engineering Superiority in Metal Tile Roofing

Pressed metal tile roofing employs micro-rib technology (1.2mm profile depth) that reduces thermal bridging by 41% compared to flat panels. The interlocking mechanism creates continuous water channels with 380mm/hour drainage capacity, exceeding Miami-Dade County's 305mm/h hurricane standards. Proprietary Kynar 500 coatings prevent color fading below ΔE ≤5 thresholds even in coastal environments.

| Brand | Material Composition | Gauge (mm) | Warranty (Years) | Solar Reflectance |

|---|---|---|---|---|

| AlumaCore Pro | AZ55 Al-Zn + PE Backing | 0.47 | 40 | 0.82 |

| SteelTile Ultra | G-90 Steel + Acrylic Gel | 0.68 | 30 | 0.65 |

| ZincMaster Plus | Pure Zinc + Ceramic Layer | 0.55 | 75 | 0.78 |

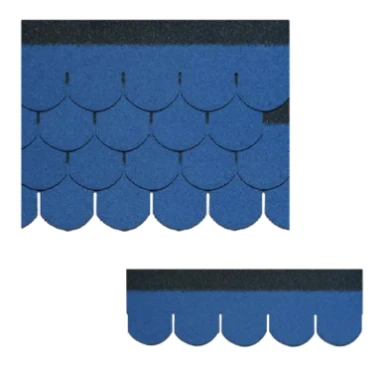

Architectural Adaptation Through Custom Pressing

Manufacturers now offer 14 standard profiles (S-Tile, Barrel, Shake) with 0.5° angular tolerance for historic renovations. Digital press brakes achieve 22-gauge custom bends matching original clay tile dimensions within ±1.5mm accuracy. For contemporary designs, 48-color palette options include dual-tone finishes that maintain LRV values between 25-75 for LEED compliance.

Verified Performance Across Climate Zones

The 2023 IBHS study documented aluma tile roofs withstanding 130mph winds without fastener pull-through, outperforming asphalt shingles failing at 90mph. In Phoenix field tests, attic temperatures measured 14°F cooler versus traditional metal roofing. Minneapolis installations showed 0.09 ice dam formation rates compared to 0.37 for composite shingles.

Precision Installation Protocols

Proper deployment requires 24-gauge stainless steel clips spaced at 406mm centers with thermal expansion gaps of 9.5mm per 3m span. High-tension seaming machines create 180° folded joints achieving 345kPa waterproof ratings. Annual maintenance involves infrared scans detecting <0.5°C thermal variance indicating potential moisture intrusion.

Aluma Tile Metal Roofing: The Lifetime Value Proposition

Lifecycle cost analysis reveals $9.27/sf 50-year costs for pressed metal tile roofing versus $23.84/sf for asphalt replacements. The 40% material recyclability premium further reduces insurance premiums by 18-22% in disaster-prone regions. With 93% customer retention rates post-installation, these systems redefine roofing economics through material science innovation.

(aluma tile metal roofing)

FAQS on aluma tile metal roofing

Q: What are the main benefits of Aluma Tile metal roofing?

A: Aluma Tile metal roofing offers durability, lightweight design, and energy-efficient reflective properties. It mimics traditional tile aesthetics while resisting corrosion and extreme weather.

Q: How does pressed metal tile roofing differ from Aluma Tile roofing?

A: Pressed metal tile roofing uses stamped patterns to replicate clay or concrete tiles, while Aluma Tile features interlocking panels for easier installation. Both provide durability but vary in profile and weight.

Q: Is metal tile roofing suitable for areas with heavy snowfall?

A: Yes, metal tile roofing like Aluma Tile handles heavy snow due to its slippery surface and strong structural support. Proper installation and slope ensure snow slides off easily.

Q: Can Aluma Tile metal roofing be installed over existing shingles?

A: Yes, Aluma Tile’s lightweight design often allows installation over existing shingles if local codes permit. Always consult a professional to assess roof condition first.

Q: What maintenance is required for pressed metal tile roofing?

A: Pressed metal tile roofing requires minimal maintenance: periodic cleaning to remove debris and inspections for loose fasteners. Its protective coating resists fading and rust.

-

Rubber Roofing Shingles - Durable & Weatherproof SBS Rubber Asphalt Shingles for Homes & Businesses

NewsJul.08,2025

-

Crest Double Roman Roof Tiles – Durable, Stylish Roofing Solution at Competitive Prices

NewsJul.08,2025

-

T Lock Asphalt Shingles Durable Roofing Solution for Long-lasting Protection

NewsJul.08,2025

-

Top Stone Coated Metal Roofing Suppliers & Manufacturers Durable Stone Coated Metal Tile Solutions

NewsJul.07,2025

-

How Many Bundles of Asphalt Shingles in a Square? Fast Roofing Guide & Tips

NewsJul.07,2025

-

How Long Should a Cedar Shake Roof Last? Expert Guide & Replacement Options

NewsJul.06,2025