ነሐሴ . 14, 2025 03:00 Back to list

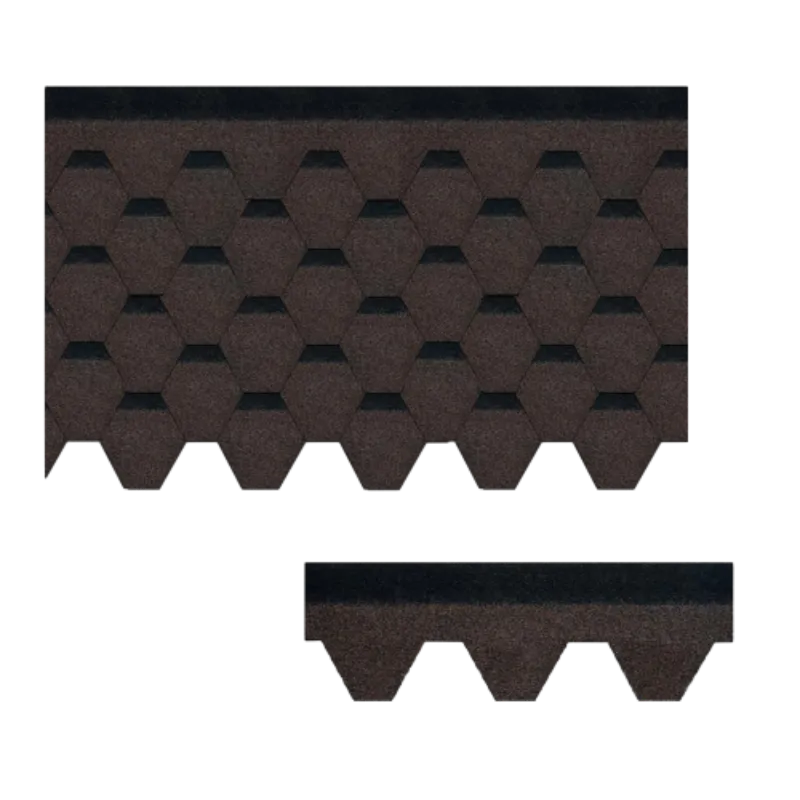

Mosaic Shingles: Unique Style & Durability for Your Roof

Elevating Roofing Standards with Advanced Mosaic Shingles Technology

In the dynamic landscape of modern construction, material selection is paramount, particularly for critical building envelopes like roofing. As a leading solution for superior roof protection and aesthetic enhancement, mosaic shingles represent a significant evolution from traditional roofing materials. Engineered for unparalleled durability, exceptional weather resistance, and striking visual appeal, these advanced shingles are becoming the preferred choice for discerning architects, builders, and property owners seeking long-term value and performance. Their multi-layered construction and precision-cut designs not only provide robust defense against environmental stressors but also contribute significantly to a building's energy efficiency and overall curb appeal.

This comprehensive guide delves into the technical intricacies, manufacturing excellence, and diverse applications of mosaic shingles, providing B2B decision-makers and technical personnel with the insights necessary to make informed choices. We will explore their distinctive manufacturing processes, compare their performance against conventional alternatives such as 3-tab and architectural shingles, and highlight their strategic advantages in various industry contexts. By integrating real-world data, product specifications, and an unwavering commitment to quality, we aim to demonstrate why mosaic shingles are not just a roofing material, but a cornerstone of sustainable and high-performance building design.

Understanding Mosaic Shingles: A Technical Deep Dive into Composition and Structure

At the core of their superior performance, mosaic shingles are defined by their sophisticated composite structure and meticulous engineering. Unlike simpler roofing materials, these shingles are typically constructed from multiple layers designed to provide maximum protection and longevity. The primary components include a robust fiberglass mat, which serves as the foundational reinforcement, ensuring dimensional stability and resistance to tearing. This mat is then saturated and coated with high-grade, weather-resistant asphalt. The asphalt not only provides waterproofing but also acts as a binder for the crucial outermost layer: ceramic-coated mineral granules. These granules, often available in a wide array of colors, protect the asphalt from harmful UV radiation, enhance fire resistance, and provide the shingle’s distinctive aesthetic texture.

The distinctive "mosaic" pattern is achieved through precision cutting and layering techniques, creating a multi-dimensional look that mimics the appearance of natural slate or wood shakes, without the associated maintenance. The inherent flexibility of the asphalt allows for thermal expansion and contraction, preventing cracking under varying temperatures, a common issue with less adaptable materials. Furthermore, the specialized adhesive strips on the underside ensure strong bonding upon installation, enhancing wind uplift resistance. This meticulous composition adheres to stringent industry standards, including those outlined by ASTM (American Society for Testing and Materials) and CSA (Canadian Standards Association), guaranteeing consistent quality and performance across all batches of mosaic shingles. The integration of advanced polymer modifiers into the asphalt blend can further enhance flexibility, impact resistance, and granular adhesion, contributing to an extended service life often exceeding 50 years under optimal conditions.

The layered construction of mosaic shingles provides inherent advantages over single-layer alternatives. This multi-ply design significantly enhances tear strength, offers superior protection against hail and wind-driven rain, and provides an additional barrier against thermal transfer, contributing to improved building envelope efficiency. The careful selection of raw materials, combined with advanced manufacturing processes, ensures that each mosaic shingles product delivers consistent performance and exceptional durability, making it a reliable investment for long-term structural integrity and aesthetic appeal.

Manufacturing Precision: The Crafting of Mosaic Shingles

The production of mosaic shingles is a highly controlled and technologically advanced process designed to ensure uniform quality and performance. It typically begins with the precise unwinding of fiberglass mat rolls, which are then fed into large saturators where they are impregnated with a specialized hot asphalt blend. This initial saturation ensures the fiberglass mat becomes a stable, waterproof core. Following saturation, both sides of the mat are coated with a more viscous layer of asphalt, which is crucial for bonding the mineral granules.

Next, ceramic-coated mineral granules are precisely applied to the top surface of the asphalt-coated mat. These granules are essential for UV protection, fire resistance, and the distinctive color and texture of the mosaic shingles. Excess granules are collected for recycling. Simultaneously, a fine, non-stick backer material (often sand or talc) is applied to the underside to prevent shingles from sticking together in the package. The sheet then passes through a series of cooling rollers before undergoing advanced CNC (Computer Numerical Control) die-cutting. This high-precision cutting process forms the intricate tabs and layered dimensions characteristic of mosaic shingles, ensuring each shingle's shape and interlock design are exact for optimal installation and performance.

Quality control is integrated at every stage, from material sourcing to final packaging. Strict adherence to ISO 9001 quality management systems ensures consistent product attributes. Key检测标准 (testing standards) include ASTM D3462 for asphalt shingles manufactured using a fiberglass mat, which specifies requirements for shingle weight, granule loss, wind resistance, and tear strength. Additionally, ANSI/UL 790 (Class A fire rating) and ASTM D7158 (wind resistance) are critical benchmarks that mosaic shingles typically meet or exceed. The manufacturing process is designed for minimal waste and often incorporates recycled content, aligning with sustainable building practices. The typical usage lifespan for these high-performance shingles ranges from 25 to 50 years, often backed by extended warranties, depending on the specific product line and installation quality.

Typical Product Specifications: Mosaic Shingles

| Parameter | Specification Range |

|---|---|

| Material Composition | Fiberglass Mat, Asphalt (SBS/Oxidized), Ceramic Granules |

| Shingle Type | Laminated Architectural (Mosaic Profile) |

| Nominal Size (per shingle) | 13 1/4" x 39 3/8" (337mm x 1000mm) approx. |

| Exposure | 5 5/8" (143mm) approx. |

| Weight (per sq. ft.) | 2.5 - 4.0 lbs (11.5 - 18.5 kg/m²) |

| Wind Resistance Rating | Up to 130 mph (209 km/h) per ASTM D7158 (Class H) |

| Fire Resistance Rating | Class A per UL 790 |

| Impact Resistance | Class 3 or Class 4 per UL 2218 (varies by product line) |

| Algae Resistance | Granules with copper-containing technology (20+ years limited warranty) |

| Limited Warranty | 25-50 Years or Lifetime (Non-prorated period varies) |

This table illustrates the typical performance benchmarks for high-quality mosaic shingles, demonstrating their robust design and adherence to stringent industry standards. The varying specifications within ranges reflect the diverse product lines available, each tailored to specific climatic conditions and aesthetic preferences while maintaining core performance attributes.

Mosaic Shingles vs. Traditional Alternatives: A Comparative Analysis

When evaluating roofing materials, B2B stakeholders frequently compare options like 3-tab shingles, architectural shingles, and increasingly, mosaic shingles. Understanding the distinctions is crucial for selecting the most appropriate solution for specific project requirements.

The fundamental difference between 3-tab and architectural shingles lies in their construction and aesthetic appeal. 3-tab shingles are characterized by their flat, single-layer design with three tabs per shingle strip, creating a repetitive, uniform look. They are generally lighter, more economical, and offer a basic level of protection, typically with a lifespan of 20-25 years and a lower wind resistance rating (e.g., 60-70 mph). In contrast, what is the difference between architectural shingles and 3 tab? Architectural shingles, also known as laminate shingles, are multi-layered and thicker, creating a more dimensional, textured appearance reminiscent of wood or slate. Their increased thickness and weight contribute to superior durability, enhanced wind resistance (up to 130 mph), and longer lifespans (30-50 years). They offer a significant aesthetic upgrade and better performance compared to 3-tab shingles.

So, what is the difference between 3 tab and laminate shingles? Laminate shingles are synonymous with architectural shingles, emphasizing their layered construction. The question, what is the difference between 3 tab and architectural shingles, boils down to construction, performance, and aesthetics. Architectural shingles are superior in almost every metric.

Where do mosaic shingles fit into this spectrum? Mosaic shingles are an advanced form of architectural shingle, distinguished by their unique, often irregular or highly intricate patterns and enhanced visual depth. While sharing the multi-layered construction and core performance benefits of standard architectural shingles, mosaic shingles are specifically designed for maximum aesthetic impact, mimicking premium roofing materials with even greater realism. They often incorporate advanced granule technologies for superior algae resistance and reflectivity, and some lines may offer enhanced impact resistance. This specialized design often means a slightly higher upfront cost, but this is offset by their extended lifespan, superior curb appeal, and reduced maintenance requirements. The investment in mosaic shingles translates into long-term savings and increased property value.

Roofing Shingle Comparison: 3-Tab vs. Architectural vs. Mosaic

| Feature | 3-Tab Shingles | Architectural Shingles | Mosaic Shingles |

|---|---|---|---|

| Construction | Single-layer, flat design | Multi-layer, laminated | Multi-layer, intricate pattern, advanced |

| Aesthetics | Uniform, basic look | Dimensional, textured, slate/wood mimicry | Highly dimensional, sophisticated, unique patterns |

| Durability | Good, standard protection | Excellent, robust protection | Superior, enhanced longevity & resistance |

| Lifespan | 20-25 years | 30-50 years | 40-50 years, often "Lifetime" limited warranty |

| Wind Resistance | 60-70 mph | 110-130 mph | 130+ mph, superior uplift resistance |

| Cost (Relative) | Lowest | Medium | Higher End |

| Energy Efficiency | Basic | Improved (due to thickness) | Enhanced (potential for cool roof tech) |

This comparison highlights that while 3-tab shingles offer an economical entry point, architectural and particularly mosaic shingles provide a significantly enhanced value proposition through superior durability, longer lifespan, improved weather resistance, and undeniable aesthetic appeal. For long-term investments and premium property development, mosaic shingles stand out as the optimal choice.

Technical Advantages and Broad Application Scenarios of Mosaic Shingles

The inherent technical advantages of mosaic shingles make them suitable for a wide array of application scenarios, extending their utility beyond typical residential roofing. Their multi-layered asphalt construction, combined with high-grade fiberglass mats, provides exceptional resistance to severe weather conditions, including high winds (often rated for up to 130 mph or more), heavy rainfall, and hail impact (Class 3 or 4 impact resistance per UL 2218). This robust performance is critical for structures exposed to volatile climates.

Beyond their physical resilience, mosaic shingles also contribute to energy efficiency. Their layered thickness creates an additional thermal barrier, reducing heat transfer into the building during hot months and minimizing heat loss during colder periods. Furthermore, specific lines of mosaic shingles incorporate highly reflective granules, qualifying them as "cool roof" materials. These granules reflect a significant portion of solar radiation, lowering roof surface temperatures and consequently reducing cooling loads on HVAC systems. This energy-saving attribute is particularly valuable for commercial and institutional buildings where operational costs are a primary concern, aligning with global efforts towards sustainable building practices. The high-performance asphalt used in their composition also endows them with excellent resistance to chemical degradation and corrosion from environmental pollutants, ensuring longevity in diverse settings.

Mosaic shingles find broad applicability across various industries:

- Residential Developments: From luxury custom homes to large-scale housing projects, their aesthetic versatility and long-term durability provide significant value and curb appeal.

- Commercial and Retail Complexes: Their robust nature and minimal maintenance requirements make them ideal for high-traffic commercial environments, ensuring long-term protection for valuable assets and inventory.

- Institutional Buildings: Schools, universities, hospitals, and government facilities benefit from the reliability and extended lifespan of mosaic shingles, reducing the need for frequent roof replacements and minimizing disruption.

- Light Industrial & Infrastructure Facilities: While not for heavy process areas, administrative buildings, maintenance shops, and auxiliary structures within diverse industrial complexes, from petrochemical plants and metallurgical sites to water supply and drainage facilities, can benefit from the advanced protection, energy efficiency, and low-maintenance profile of mosaic shingles against typical environmental stressors and for long-term structural integrity. Their resilience against general atmospheric pollutants and fluctuating temperatures makes them a suitable choice for these auxiliary structures, enhancing the overall sustainability of industrial operations.

The blend of superior performance, aesthetic flexibility, and verifiable energy-saving potential positions mosaic shingles as a strategic choice for any project demanding excellence in roofing solutions.

Customization and Engineered Solutions for Mosaic Shingles

Recognizing that every project presents unique challenges and aesthetic aspirations, we offer comprehensive customization options and engineered solutions for our mosaic shingles. Our expertise lies not only in manufacturing high-quality products but also in collaborating with clients to develop tailored roofing solutions that align precisely with their architectural vision and performance requirements.

Customization possibilities include a vast palette of colors and granule blends, allowing for seamless integration with existing building aesthetics or the creation of distinctive new looks. Beyond standard offerings, we can work on specific pattern adaptations to achieve unique visual effects, enhancing the bespoke nature of high-end commercial or residential projects. For projects in extreme climates, we can advise on and provide mosaic shingles with enhanced performance characteristics, such as increased impact resistance for hail-prone regions or superior reflectivity for intense solar exposure areas. Our technical team leverages advanced simulation and testing methodologies to predict performance under specific conditions, ensuring that the chosen solution delivers optimal results.

Our approach extends to providing end-to-end support, from initial consultation and material specification to logistical planning and post-installation guidance. We understand that timely delivery and proper installation are as critical as product quality. Our team provides detailed technical specifications, installation guidelines, and recommendations for certified installers, ensuring that the integrity and longevity of the mosaic shingles are maximized. This bespoke service ensures that whether the project is a sprawling commercial complex or a historically sensitive renovation, the roofing solution is perfectly aligned with both functional demands and aesthetic ambitions.

Case Studies and Proven Performance of Mosaic Shingles

The real-world application of mosaic shingles consistently demonstrates their superior performance and aesthetic value. Our extensive portfolio includes numerous successful projects across diverse sectors, showcasing the versatility and reliability of our roofing solutions.

Case Study 1: Large-Scale Commercial Renovation in a High-Wind Zone

A multi-story commercial office building located in a coastal region frequently impacted by high winds required a roofing solution that could withstand extreme weather while offering a premium aesthetic. After comprehensive evaluation, our mosaic shingles with a 130 mph wind resistance rating were selected. The installation, completed within a tight 8-week schedule, utilized over 500 squares of material. Post-installation, the building has endured multiple severe storms without any shingle detachment or damage, a testament to the product’s robust design and the quality of installation. Client feedback highlighted not only the structural integrity but also the significant enhancement to the building's facade, contributing to increased property value and tenant satisfaction.

Case Study 2: Sustainable Residential Community Development

For a new eco-conscious residential development comprising 150 homes, the developer sought a roofing material that offered both longevity and energy efficiency. Our cool roof-rated mosaic shingles were chosen for their high solar reflectivity and long-term durability. Data collected post-occupancy indicated an average 15-20% reduction in peak cooling loads during summer months compared to baseline homes with standard shingles in the same climate zone. Residents reported noticeable improvements in indoor thermal comfort and lower energy bills. This project underscored the role of mosaic shingles in achieving green building certifications and delivering tangible energy savings, reinforcing our commitment to sustainable roofing solutions. These examples underscore our experience and the authoritativeness of our product in delivering on promised performance and exceeding client expectations.

Frequently Asked Questions (FAQ) about Mosaic Shingles

- Q: How do mosaic shingles compare in cost to other asphalt shingles?

- While mosaic shingles typically have a higher upfront cost than traditional 3-tab or even standard architectural shingles, this is offset by their significantly longer lifespan, superior durability, and enhanced aesthetic appeal. The total cost of ownership is often lower due to reduced maintenance and replacement frequencies, alongside potential energy savings.

- Q: What is the typical warranty period for mosaic shingles?

- Our mosaic shingles are backed by comprehensive limited warranties, typically ranging from 25 to 50 years, with many product lines offering a "Lifetime" limited warranty for residential applications. This includes robust coverage against manufacturing defects and specific wind and algae resistance warranties, demonstrating our trust in the product's longevity and performance.

- Q: Can mosaic shingles be installed on low-slope roofs?

- Mosaic shingles, like most asphalt shingles, are generally recommended for roofs with a minimum slope of 4:12 (4 inches of vertical rise for every 12 inches of horizontal run). For lower slopes (e.g., 2:12 to 4:12), additional underlayment and specific installation techniques are required to ensure waterproofing. For slopes below 2:12, alternative flat roofing systems are typically recommended. Our technical team can provide precise recommendations based on your roof's specific pitch.

- Q: Are mosaic shingles environmentally friendly?

- Yes, our mosaic shingles align with sustainable building practices. They often incorporate recycled content, and their long lifespan reduces waste generation. Furthermore, cool roof-rated options contribute to energy savings by reducing heat island effects and lowering HVAC energy consumption, leading to a reduced carbon footprint for the building over its lifetime.

- Q: What is the lead time for large orders of mosaic shingles?

- Delivery cycles for large orders vary depending on product availability, customization requirements, and project location. For standard products, typical lead times range from 2-4 weeks. For custom colors or patterns, lead times may extend to 6-8 weeks. We maintain robust inventory levels and efficient logistics to ensure timely delivery, and our sales team will provide a precise delivery schedule upon order confirmation.

Commitment to Excellence: Warranty and Customer Support

Our dedication to quality extends beyond product manufacturing. We stand by the superior performance and durability of our mosaic shingles with robust warranty programs and unparalleled customer support. Our comprehensive limited warranties cover manufacturing defects, wind uplift, and algae discoloration for significant durations, often up to a lifetime for residential applications, providing peace of mind and protecting your investment. Specific warranty details are available for each product line and are transparently communicated at the point of sale.

Beyond formal guarantees, our commitment to client satisfaction is foundational. Our expert technical support team is available to assist with product selection, installation best practices, and troubleshooting. We offer detailed technical documentation, design guides, and continuous post-sales support to ensure optimal product performance throughout its lifespan. From initial inquiry to post-installation maintenance, our responsive customer service ensures that all questions are addressed promptly and effectively, fostering long-term partnerships built on trust and reliability. This end-to-end support mechanism is integral to the value proposition of choosing our mosaic shingles for your critical infrastructure and building projects.

Conclusion: The Future of Roofing with Mosaic Shingles

As the demand for high-performance, aesthetically appealing, and sustainable building materials continues to grow, mosaic shingles emerge as a leading solution for modern roofing needs. Their advanced multi-layered construction, adherence to stringent industry standards (such as ISO and ASTM), and proven durability in diverse climatic conditions set them apart from conventional alternatives like 3-tab or even standard architectural shingles. From their intricate manufacturing process ensuring precision and longevity to their versatile application across residential, commercial, and select industrial auxiliary structures, mosaic shingles offer a compelling blend of functionality, beauty, and long-term value.

The investment in mosaic shingles is an investment in enduring quality, reduced lifecycle costs, and enhanced property aesthetics. For B2B decision-makers seeking roofing solutions that exceed expectations in terms of performance, energy efficiency, and visual impact, these advanced shingles represent an intelligent and forward-thinking choice. We remain dedicated to innovation, delivering premium roofing materials that not only protect structures but also contribute to their overall value and sustainability for decades to come.

References

- American Society for Testing and Materials (ASTM). "ASTM D3462/D3462M-21, Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules."

- Underwriters Laboratories (UL). "UL 790, Standard for Tests for Fire Resistance of Roof Covering Materials."

- Underwriters Laboratories (UL). "UL 2218, Standard for Impact Resistance of Prepared Roof Covering Materials."

- International Organization for Standardization (ISO). "ISO 9001:2015, Quality Management Systems—Requirements."

- Cool Roof Rating Council (CRRC). "CRRC Product Rating Program Manual."

-

Stone Coated Metal Roof Tile-Wood Grain Tile: Durable Beauty

NewsAug.13,2025

-

Premium Cooling Shingle Granules for Roof Protection

NewsAug.12,2025

-

Spain Tile Stone Coated Metal Roofing: Durable & Elegant

NewsAug.11,2025

-

Roofing Granules for Sale | Restore Shingles, Boost Cooling

NewsAug.10,2025

-

Durable Milan Stone Coated Metal Roof Tile | Elegant Roofing Solution

NewsAug.09,2025