Oct . 27, 2025 11:55 Back to list

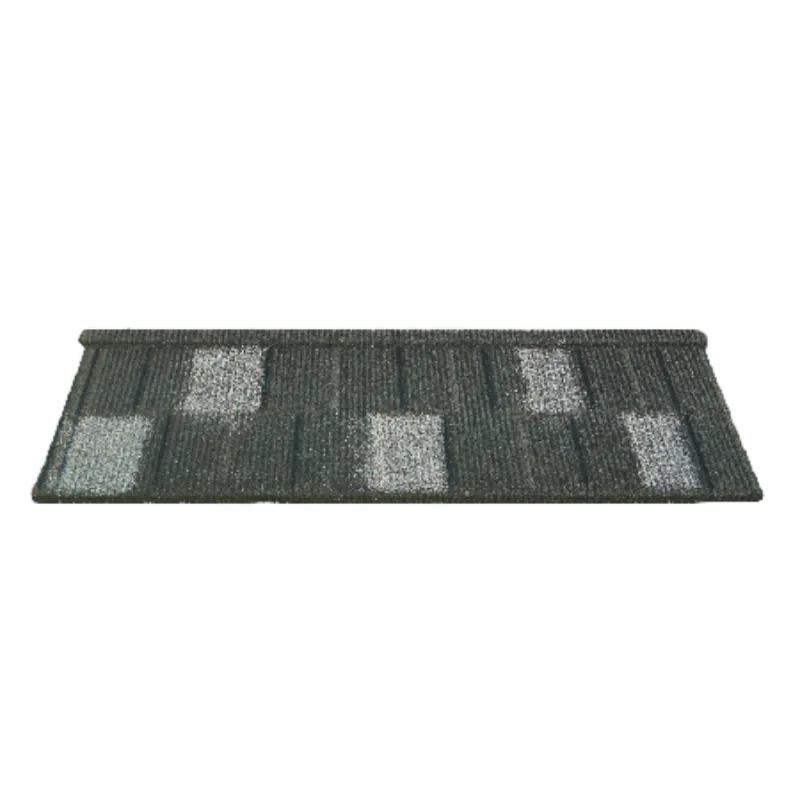

Stone Coated Metal Roof Tile-Flat Tile | Durable, Light

Field Notes on Modern Roofing: Why Flat-Profile Stone Coated Tiles Are Having a Moment

If you’ve been watching the roofing market—contractors, architects, even hands-on homeowners—you’ve probably noticed a swing toward quiet, minimal profiles with tough-as-nails performance. Enter the Stone Coated Metal Roof Tile-Flat Tile. To be honest, I didn’t expect a “flat” tile to make this much noise (figuratively), but the blend of modern lines and old-school durability is hard to ignore.

What’s driving the trend

Designers want shadow-less, contemporary roofs; facility managers want low maintenance; homeowners want storm resilience. Stone-coated metal checks those boxes. The flat profile keeps it sleek, and the stone chips temper rain noise. Many customers say it “looks like slate, performs like steel.” Not a bad combo.

Key specifications (real-world friendly)

| Parameter | Value |

|---|---|

| Tile size | 1340 × 420 mm |

| Effective dimension | 1270 × 370 mm |

| Coverage area | ≈ 0.48 m²/tile (real-world use may vary) |

| Tiles per m² | ≈ 2.16 pcs/m² |

| Weight | ≈ 2.7 kg/pc |

| Steel thickness | 0.4–1.0 mm (project-dependent) |

| Origin | No.B2305, Times Ark Building, Guangan Street, Shijiazhuang, China |

How it’s made (short version)

Base metal is usually Al‑Zn coated steel (AZ) formed into a flat profile, primed, then layered with an acrylic binder and natural stone granules (often basalt). A clear overglaze is kiln-cured for chip lock-in and UV protection. Routine testing references include ASTM A792 (base metal), ISO 9227 (salt spray), ASTM D3359 (adhesion), UL 2218 (hail impact), and ASTM E108/UL 790 (fire). Service life? Around 30–50 years depending on climate, installation quality, and maintenance.

Application scenarios

- Residential new builds and retrofits (lightweight for aging rafters).

- Coastal resorts and villas (better corrosion resistance vs. plain steel).

- Public buildings, schools, worship halls—where low noise and non-combustibility matter.

- Mountain and snow zones; the flat tile sheds snow predictably.

Field feedback and test data

Installers report fast coverage rates with fewer offcuts than S‑profile tiles. One contractor shared wind-uplift lab results around 2.4–3.0 kPa (ASTM E1592 protocols)—your mileage may vary with purlin spacing and fasteners. UL 2218 Class 4 impact ratings are commonly achievable with this class of product. Several batches I’ve seen carried ISO 9001 factory certification and CE per EN 14782.

Advantages at a glance

- Lightweight yet robust; easy on structures and transport.

- Stone coating softens rain noise—surprisingly noticeable.

- Flat aesthetic plays nicely with contemporary elevations.

- Color stability with UV-resistant overglaze; fewer streaking issues.

Vendor snapshot (what to check)

| Vendor | Base steel | Certs | Warranty | Lead time |

|---|---|---|---|---|

| Cool Roof Materials (Stone Coated Metal Roof Tile-Flat Tile) | AZ steel, 0.4–1.0 mm | ISO 9001, CE (≈ EN 14782) | Up to 30–50 yrs (conditions apply) | ≈ 2–4 weeks |

| Local Brand B | AZ steel, 0.5 mm | UL 2218, ISO 9227 report | 25–40 yrs | Around 3–6 weeks |

| Generic Import C | Mixed grades | Seller claims only | Varies | Stock dependent |

Customization

Colors (charcoal, terracotta, coffee, forest), matte or satin overglaze, steel thickness to spec, and full accessory kits (ridge, hip, eaves, fasteners). For coastal jobs, ask for higher AZ coating mass and documented salt-spray hours.

Case notes from the field

- Coastal villa retrofit: Stone Coated Metal Roof Tile-Flat Tile replaced aged concrete tiles; roof weight dropped ≈ 60%, crew finished in 3 days, noticeable rain-noise reduction.

- Mountain lodge: Class 4 impact rating helped with frequent hail; snow guards added at eaves, zero shingle blow-offs over two winters (anecdotal but consistent).

Standards and references

- ASTM A792/A792M – Standard Specification for Steel Sheet, 55% Aluminum-Zinc Alloy-Coated by the Hot-Dip Process.

- ISO 9227 – Corrosion tests in artificial atmospheres — Salt spray tests.

- UL 2218 – Standard for Impact Resistance of Prepared Roof Covering Materials.

- ASTM E108 / UL 790 – Fire Tests of Roof Coverings.

- EN 14782 – Self-supporting metal sheet for roofing, external cladding and internal lining.

-

Stone Coated Metal Roof Tile-Spain Tile: Durable, Elegant

NewsNov.10,2025

-

Roofing Granules for Sale – UV-Stable, Colorfast, Bulk

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Classic Tile: Durable & Light

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Nosen Tile | 50-Year Warranty

NewsNov.10,2025

-

Roofing Granules for Sale – UV-Stable, Colorfast, Bulk

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile Durable & Light

NewsNov.03,2025