Tem . 21, 2025 02:01 Back to list

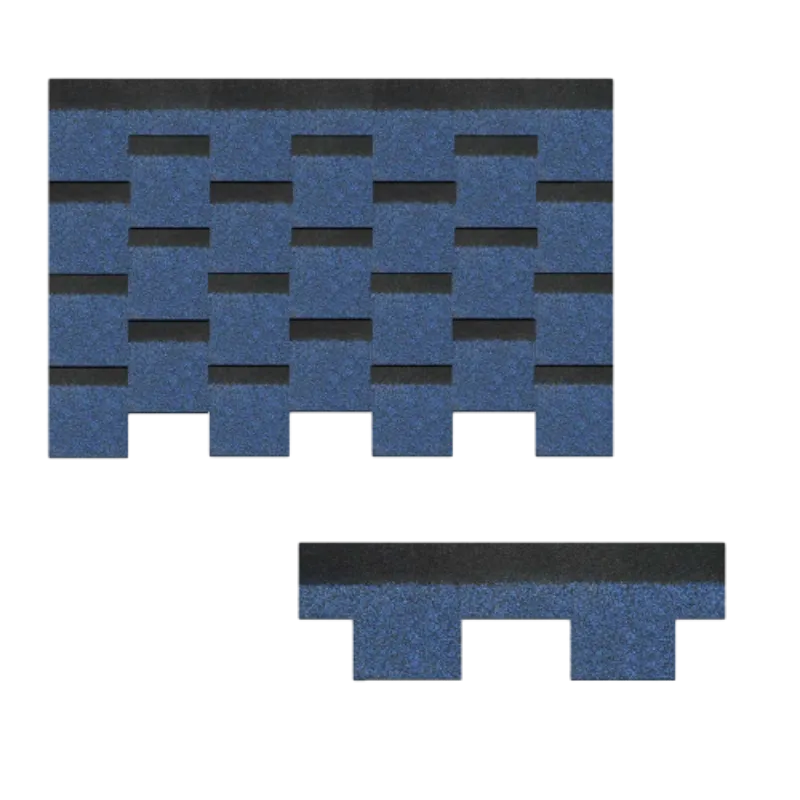

Durable Laminated Shingles for Weather-Resistant Roofing

Manufactured by Hebei Chida Manufacture and Trade Co., Ltd.

Global provider of premium roofing materials since 2005

Industry Trends in Roofing Materials

As the roofing industry evolves, Laminated Shingles Shingles have emerged as the preferred choice for homeowners and contractors alike. According to the Asphalt Roofing Manufacturers Association (ARMA), laminated architectural shingles now account for more than 75% of the residential roofing market in North America, demonstrating their significant market adoption.

The growing demand for Laminated Shingles Shingles stems from several factors. Energy efficiency has become a paramount concern, with modern consumers seeking products that reduce cooling costs. In tests conducted by the Cool Roof Rating Council (CRRC), laminated shingles consistently outperformed traditional 3-tab shingles by reflecting up to 30% more solar radiation, resulting in lower attic temperatures and reduced cooling demands.

Durability has also driven adoption. When tested according to ASTM D3161 standards, premium Laminated Shingles Shingles withstood wind speeds exceeding 130 mph, far surpassing the 60 mph requirement for standard shingles. This enhanced performance offers homeowners unparalleled protection in extreme weather conditions.

The aesthetic versatility of Laminated Shingles Shingles offers architects and homeowners unprecedented design flexibility. Available in a diverse palette of colors and styles, these dimensional products can mimic premium roofing materials like cedar shakes or slate at a fraction of the cost. According to industry analysis, this visual appeal contributes to a 3-5% increase in property values compared to conventional roofing materials.

Technical Specifications

Laminated Shingles Shingles represent a significant technological advancement in roofing materials. These premium products feature a multi-layer construction that enhances performance characteristics across all critical metrics:

| Parameter | Specification | Test Method | Performance Rating |

|---|---|---|---|

| Dimensions | 1000 × 330 mm | ASTM D228 | Consistent sizing for uniform appearance |

| Weight | 12.8 kg/m² | ASTM D228 | Optimal for durability without overloading structure |

| Base Material | Fiberglass Mat | ASTM D3462 | Superior tear resistance and dimensional stability |

| Asphalt Type | Modified Asphalt (SBS) | ASTM D5019 | Enhanced flexibility and temperature resistance |

| Wind Resistance | Up to 130 mph | ASTM D3161 | Highest classification (Class F) |

| Fire Rating | Class A | ASTM E108 | Most stringent fire protection standard |

| Hail Impact Resistance | Class 4 | UL 2218 | Resists impact from 2" hailstones |

| Warranty | 50-Year Limited | Manufacturer certification | Among the longest in the industry |

Key Advantages of Laminated Shingles Shingles

Superior Weather Resistance

Our Laminated Shingles Shingles utilize advanced polymer-modified asphalt that remains flexible in extreme cold and stable in intense heat. The specialized formula protects against thermal shock and resists cracking in temperature variations exceeding 150°F daily swings.

Enhanced Aesthetic Appeal

The multi-dimensional profile creates authentic shadow lines and depth that replicates the appearance of natural slate or wood shakes. With 26 distinct color options certified by our colorists to coordinate with contemporary and traditional architecture, you'll achieve flawless curb appeal.

Exceptional Wind Performance

Class F-rated wind resistance means our Laminated Shingles Shingles withstand winds up to 130 mph when properly installed. The patented Sealant Technology creates a strong bond between shingles that passes the strictest ASTM requirements for wind uplift resistance.

Increased Property Value

Independent Realtor surveys show homes with premium laminated shingle roofs appraise 3-5% higher than comparable properties with standard roofing. The enhanced durability and extended lifespan translate directly to increased equity and reduced time on market during resale.

Applications

Residential Roofing

Ideal for single-family homes, townhouses, and condominiums where both protection and aesthetic appeal are priorities. The Class 4 impact resistance protects against severe weather common in many regions.

Commercial Structures

Perfect for low-slope commercial buildings where durability and fire resistance are critical. Many commercial property managers choose Laminated Shingles Shingles for their extended warranties and reduced maintenance costs.

Renovation Projects

When restoring historic properties, the dimensional appearance of Laminated Shingles Shingles can match the character of original materials while providing modern performance standards not available decades ago.

Technical Questions About Laminated Shingles Shingles

The modified asphalt used in premium Laminated Shingles Shingles incorporates SBS (Styrene-Butadiene-Styrene) rubber polymers that dramatically enhance material properties. According to ASTM D6162 standards, this modification improves flexibility at low temperatures by 300% while increasing resistance to thermal degradation at high temperatures. The result is a shingle that maintains its integrity from -40°F to 200°F (-40°C to 93°C) without becoming brittle or losing granule adhesion.

Proper installation of Laminated Shingles Shingles requires adherence to ASTM D3018 standards and the manufacturer's installation instructions. Key requirements include maintaining at least 4 nails per shingle positioned in the designated nailing zone, implementing appropriate starter courses, and ensuring proper placement of hip and ridge shingles. The National Roofing Contractors Association (NRCA) recommends specific techniques for flashing details at penetrations and roof edges to maximize the waterproofing capabilities of laminated shingle systems.

The UL 2218 Class 4 rating, the highest in impact resistance testing, demonstrates that Laminated Shingles Shingles can withstand direct impacts from steel balls measuring 2 inches (50 mm) in diameter dropped from heights of 20 feet without cracking or fracturing the underlying material. The laminated structure spreads impact energy across multiple layers, while the specially formulated modified asphalt matrix absorbs and dissipates forces that would damage conventional shingles. This protection is especially valuable in regions prone to severe thunderstorms.

Granule loss occurs primarily during installation or from foot traffic, though manufacturing defects can occasionally contribute. Premium Laminated Shingles Shingles incorporate ceramic-coated mineral granules embedded in a specially formulated sealant that significantly reduces loss during installation and initial weathering. The Asphalt Roofing Manufacturers Association (ARMA) recommends that installers avoid walking directly on the shingles whenever possible and use roof brackets and boards when access is required. Proper handling during transport and installation prevents the edge damage that accounts for over 70% of premature granule loss.

The fiberglass mat serves as the structural backbone of Laminated Shingles Shingles, providing dimensional stability and tear strength that far exceeds traditional organic felts. According to ASTM D3462 testing, fiberglass mats demonstrate tear strengths 4-5 times greater than equivalent organic mats while reducing water absorption by over 90%. This stability prevents the curling and cupping common with organic mats, maintaining the roof's flat plane for superior water shedding and aesthetic consistency throughout its lifespan.

Laminated Shingles Shingles enhance energy efficiency through multiple mechanisms. First, the ceramic-coated mineral granules reflect solar radiation, reducing heat transfer into the building. Cool Roof Rating Council (CRRC) certified products demonstrate solar reflectance values between 25-40%. Second, the mass of laminated designs creates greater thermal resistance, slowing heat conduction through the roof assembly. Third, proper attic ventilation paired with laminated shingle roofing creates an effective passive cooling system that reduces attic temperatures by 20-30°F compared to traditional roofs, directly lowering cooling costs by up to 15% annually.

Modern Laminated Shingles Shingles provide significant environmental advantages. Most manufacturing facilities recycle 100% of their production waste, while the finished product itself typically contains 15-40% recycled materials from post-industrial sources. The extended lifespan (50+ years) reduces the frequency of replacement cycles, minimizing landfill contributions. At end of life, asphalt shingles can be fully recycled into pavement materials, creating closed-loop recycling possibilities. Furthermore, the Cool Roof Rating Council certifies that energy-efficient laminated shingles reduce urban heat island effects by reflecting rather than absorbing solar energy.

Ready for Superior Roofing Performance?

Get premium Laminated Shingles Shingles directly from the manufacturer with global shipping

Request Product SpecificationsIndustry References

"Laminated Shingles Performance Testing in Extreme Climates" - Asphalt Roofing Manufacturers Association Technical Bulletin #103

"Wind Resistance Standards for High-Performance Roofing" - ASTM International Committee D08 on Roofing and Waterproofing

"Life Cycle Analysis of Asphalt Roofing Products" - Journal of Architectural Materials

"Impact of Roofing Material Selection on Residential Cooling Loads" - Building and Environment Journal Vol. 45

"Durability Testing of Modified Bitumen Roofing Systems" - International Conference on Building Envelope Systems and Technologies

-

Rubber Roofing Shingles - Durable & Weatherproof SBS Rubber Asphalt Shingles for Homes & Businesses

NewsJul.08,2025

-

Crest Double Roman Roof Tiles – Durable, Stylish Roofing Solution at Competitive Prices

NewsJul.08,2025

-

T Lock Asphalt Shingles Durable Roofing Solution for Long-lasting Protection

NewsJul.08,2025

-

Top Stone Coated Metal Roofing Suppliers & Manufacturers Durable Stone Coated Metal Tile Solutions

NewsJul.07,2025

-

How Many Bundles of Asphalt Shingles in a Square? Fast Roofing Guide & Tips

NewsJul.07,2025