Sep . 22, 2025 18:55 Back to list

Stone Coated Metal Roof Tile - Spain Tile Style & Durability

Advancing Roofing Solutions: The Rise of Stone Coated Metal Roof Tiles

The global construction and infrastructure sectors are continually seeking innovative materials that offer superior durability, aesthetic versatility, and long-term value. In this pursuit, advanced roofing solutions have become a critical focus for B2B decision-makers, architects, and engineers. Modern trends emphasize not just immediate cost-effectiveness but also lifecycle performance, environmental impact, and architectural integration. This demand has spurred significant advancements in roofing technology, moving beyond traditional materials to embrace solutions that offer enhanced resilience and sustainability.

One such innovation gaining substantial traction across diverse markets is the Stone Coated Metal Roof Tile-Spain Tile. This product category combines the robustness of steel with the aesthetic appeal of natural stone and traditional ceramic tiles, delivering a high-performance roofing solution suitable for a wide array of demanding applications. Its unique composition and manufacturing process address many of the challenges associated with conventional roofing materials, positioning it as a preferred choice for projects requiring both engineering excellence and refined visual appeal.

Industry Trends and Market Dynamics in High-Performance Roofing

Current industry trends in roofing are heavily influenced by the imperative for sustainable construction, stringent building codes, and evolving aesthetic preferences. Key drivers include:

- Energy Efficiency: A growing emphasis on cool roof technologies and materials with high solar reflectivity and thermal emissivity to reduce building cooling loads, in line with green building certifications like LEED and BREEAM.

- Durability and Resilience: Increased demand for roofing systems capable of withstanding extreme weather events, including high winds, heavy hail, and seismic activity, particularly in regions prone to such conditions.

- Longevity and Low Maintenance: Preference for roofing solutions that offer extended service life (50+ years) and require minimal maintenance, thereby reducing the total cost of ownership.

- Aesthetic Versatility: The need for materials that can replicate the traditional appearance of clay, slate, or wood shingles while offering superior performance, allowing for greater architectural freedom without compromising functionality.

- Environmental Responsibility: Focus on roofing products manufactured from recycled content, that are recyclable at the end of their life, and that contain fewer volatile organic compounds (VOCs).

The market for advanced metal roofing, including solutions like the Stone Coated Metal Roof Tile-Spain Tile, is projected to expand significantly, driven by these factors and the inherent advantages these products offer over conventional options. Specifically, stone-coated metal roofs address the demand for lightweight, high-strength, and aesthetically pleasing solutions that excel in performance under diverse environmental conditions.

Technical Specifications of Stone Coated Metal Roof Tile-Spain Tile

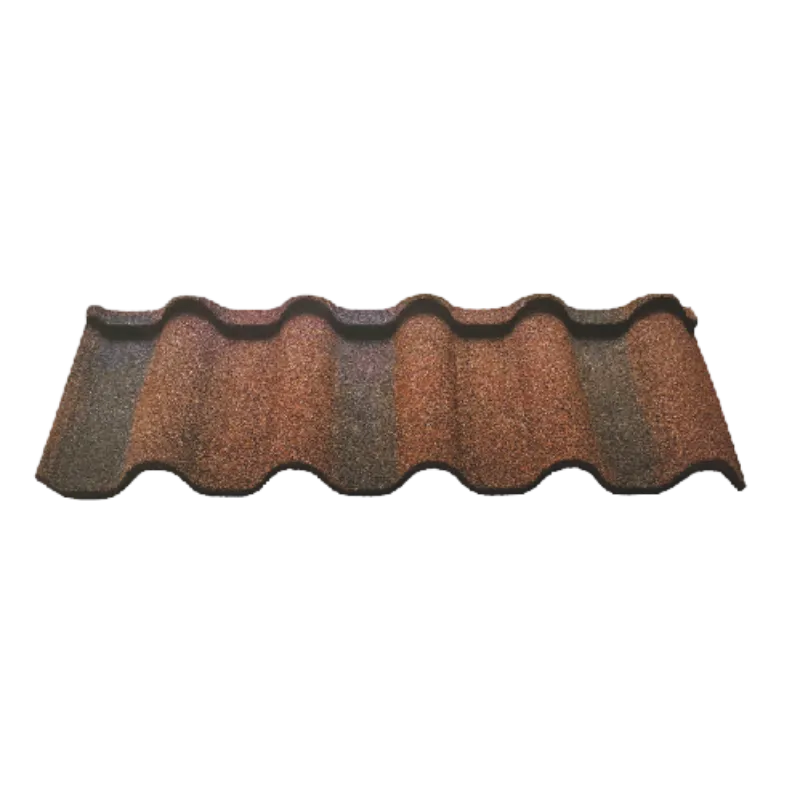

The Stone Coated Metal Roof Tile-Spain Tile is engineered for optimal performance and aesthetic fidelity, specifically designed to emulate the classic barrel-style ceramic tiles characteristic of Spanish architecture. Its multi-layered composition ensures exceptional durability and longevity.

Core Material and Coatings:

- Base Steel: High-grade Galvalume steel (Al-Zn coated steel), typically G90 or AZ50/AZ150, offering superior corrosion resistance compared to galvanized steel. Common gauges range from 26-gauge (0.45mm) to 24-gauge (0.55mm), providing an optimal balance of strength and flexibility.

- Surface Pre-treatment: Application of a chromate or non-chromate conversion coating to enhance adhesion for subsequent layers and further improve corrosion protection.

- Primer Coat: An acrylic or epoxy-based primer applied to both sides of the steel, ensuring maximum adhesion of the stone chip layer and acting as an additional barrier against moisture.

- Stone Chip Layer: Composed of natural basalt rock granules, crushed and coated with ceramic pigments, then bonded to the primer with a proprietary acrylic resin adhesive. These chips provide the tile's aesthetic finish, UV protection, and sound dampening qualities. The "Spain Tile" profile dictates a specific curvature and texture.

- Clear Acrylic Overglaze: A transparent acrylic layer applied over the stone chips, which seals the surface, enhances UV resistance, prevents color fading, and adds an extra layer of protection against environmental elements.

Performance Parameters:

| Parameter | Specification for Stone Coated Metal Roof Tile-Spain Tile |

|---|---|

| Material Composition | Galvalume Steel (AZ50/AZ150), Acrylic Resin, Natural Basalt Stone Granules, Acrylic Overglaze |

| Tile Dimensions (Approx.) | 1340mm x 420mm (Overall), 1250mm x 370mm (Effective Coverage) |

| Base Steel Thickness | 0.40mm - 0.55mm (Typical) |

| Weight (Per sq. meter) | 4.5 - 6.5 kg/m² (approx. 1/7th weight of traditional clay tiles) |

| Fire Rating | Class A (Non-combustible material when installed over non-combustible decking) |

| Wind Resistance | Up to 120 mph (190 km/h) / ASTM D3161 Class F, depending on installation methods |

| Hail Impact Resistance | Class 4 (UL 2218, highest rating) against 2-inch hail stones |

| UV Resistance | Excellent, maintains color stability over decades |

| Thermal Reflectivity | High, contributes to cool roof performance and energy savings |

| Lifespan | 50+ years, backed by long-term warranties |

These specifications underscore the advanced engineering behind Stone Coated Metal Roof Tile-Spain Tile, making it a robust and reliable choice for demanding roofing projects.

Detailed Manufacturing Process Flow of Stone Coated Metal Roof Tile-Spain Tile

The production of Stone Coated Metal Roof Tile-Spain Tile involves a meticulously controlled, multi-stage process, ensuring precision, consistency, and adherence to international quality standards such as ISO 9001 for quality management and relevant ASTM/ANSI standards for material performance. The process leverages advanced coil coating and profiling technologies.

Manufacturing Steps:

- Coil Feeding and Cleaning: High-quality Galvalume (Al-Zn alloy coated) steel coils, often 0.45mm to 0.55mm thick, are uncoiled and passed through a series of degreasing and cleaning baths to remove oils, dirt, and surface impurities, ensuring optimal adhesion for subsequent coatings.

- Pre-treatment (Chemical Conversion Coating): The cleaned steel surface undergoes a chemical conversion coating process (e.g., chromate or zirconium-based treatment). This creates a microscopic crystalline layer that enhances corrosion resistance and provides an excellent bonding surface for the primer.

- Primer Application and Curing: A specialized primer, typically an epoxy or acrylic-based resin, is precisely applied to both sides of the pre-treated steel sheet. This layer is crucial for adhesion of the stone granules and provides an additional protective barrier. The primed coil then passes through an oven for high-temperature curing, ensuring the primer is fully cross-linked and hardened.

- Stone Granule Application: While the primer coat is still wet and tacky, uniformly sized natural basalt stone granules, which have been ceramic-coated for permanent color, are electrostatically applied to the upper surface of the sheet. The electrostatic charge ensures even distribution and strong adhesion. This process is critical for achieving the desired aesthetic and protective qualities.

- Second Curing Cycle: The granule-coated sheet undergoes another curing cycle in a controlled oven environment. This step firmly bonds the stone chips to the primer and steel substrate, making them incredibly durable and resistant to shedding.

- Clear Acrylic Overglaze Application and Final Curing: A transparent acrylic overglaze is applied evenly over the stone-coated surface. This clear coat seals the granules, provides enhanced UV protection, prevents color fading, and adds an extra layer of weather resistance. A final curing stage ensures this protective layer is fully polymerized.

- Profiling/Pressing (Spain Tile Design): The now fully coated and cured flat sheets are fed into a specialized roll-forming and pressing machine. Here, through precise hydraulic pressing and profiling, the flat sheets are formed into the distinctive contoured shape of the Spain Tile, characterized by its elegant curves and ridges, which replicate traditional Spanish clay tiles. This step gives the product its final architectural form and structural rigidity.

- Quality Control and Packaging: Each finished tile undergoes rigorous quality inspections, checking for uniform coating, granule adhesion, dimensional accuracy, and color consistency. Tiles are then carefully stacked and packaged, often with protective interleaving, ready for shipment to project sites worldwide.

This elaborate manufacturing process, integrating material science with advanced engineering, results in a roofing product that not only meets but often exceeds industry standards for performance, durability, and aesthetic appeal. The adherence to standards like ISO 9001 and testing against ASTM E108 (fire resistance) and ASTM D3161 (wind resistance) ensures product reliability and consistency.

Technical Advantages and Performance Characteristics

The inherent design and material science behind Stone Coated Metal Roof Tile-Spain Tile confer a multitude of technical advantages that make it a superior choice for a broad spectrum of projects. These benefits directly translate into reduced lifecycle costs, enhanced structural integrity, and improved building performance.

- Exceptional Durability and Longevity: The Galvalume steel substrate combined with the multi-layer coating system offers unparalleled resistance to corrosion, UV degradation, and physical damage. With an anticipated service life of 50 years or more, it significantly outperforms traditional roofing materials.

- Superior Weather Resistance: Engineered to withstand extreme conditions, these tiles offer:

- High Wind Uplift: The interlocking panel design and robust fastening system enable resistance to wind speeds up to 120 mph (190 km/h), crucial for hurricane-prone regions.

- Hail Impact Resistance: Achieves a UL 2218 Class 4 rating, providing excellent protection against large hailstones and reducing the risk of structural damage and insurance claims.

- Fire Resistance: Rated as Class A fire resistant (when installed correctly), these tiles contribute significantly to building safety by preventing external flame spread.

- Freeze-Thaw Stability: The non-porous stone coating prevents water absorption, eliminating issues of cracking or delamination due to freeze-thaw cycles.

- Lightweight Design: At approximately 4.5-6.5 kg/m², these tiles are significantly lighter than concrete or clay tiles, reducing the structural load on the building. This can lead to cost savings in structural framing and foundation design for new construction and makes them an excellent option for re-roofing over existing structures without requiring extensive reinforcement.

- Energy Efficiency (Cool Roof Properties): The natural stone granules and proprietary acrylic overglaze contribute to high solar reflectivity and thermal emissivity. This helps to reduce heat absorption, lowering attic temperatures and subsequently decreasing air conditioning costs, particularly in warm climates.

- Acoustic Performance: The stone chip layer acts as an excellent sound dampener, significantly reducing noise from rain, hail, and external sources, enhancing indoor comfort.

- Aesthetic Versatility and Architectural Harmony: The "Spain Tile" profile authentically replicates the traditional and elegant appearance of Spanish clay tiles, available in a wide spectrum of colors to complement diverse architectural styles, from classic Mediterranean to contemporary designs.

- Environmental Sustainability: Made from high-recycled content steel and being 100% recyclable at the end of its long life, this product aligns with modern sustainable building practices and contributes to reduced environmental footprint.

These advantages solidify the position of Stone Coated Metal Roof Tile-Spain Tile as a premium, high-performance roofing solution, delivering exceptional value over its extended lifespan.

Figure 1: High-resolution depiction of Stone Coated Metal Roof Tile-Spain Tile showcasing its intricate profile and stone finish.

Application Scenarios and Target Industries

The unique combination of durability, aesthetic appeal, and high performance makes Stone Coated Metal Roof Tile-Spain Tile exceptionally versatile across numerous application scenarios and target industries. Its ability to provide both robust protection and architectural elegance broadens its scope beyond typical industrial applications to encompass commercial, residential, and institutional sectors.

Key Application Areas:

- High-End Residential Construction: For luxury homes, villas, and estates where a premium aesthetic is paramount, particularly those designed with Mediterranean, Spanish Colonial, or traditional European architectural themes. Its longevity and low maintenance appeal to discerning homeowners.

- Commercial and Hospitality Projects: Ideal for resorts, boutique hotels, restaurants, and retail centers seeking a distinctive, upscale appearance combined with long-term performance and brand consistency. Its resistance to harsh weather ensures continuous protection for commercial assets.

- Institutional and Public Buildings: Schools, universities, municipal buildings, and cultural centers can benefit from its durability, fire resistance, and minimal maintenance requirements, contributing to safe and aesthetically pleasing public infrastructure.

- Historical Renovations and Restorations: The ability of the Spain Tile profile to authentically mimic traditional clay tiles makes it an excellent choice for renovating historical properties or new construction in historic districts, preserving architectural heritage while integrating modern performance.

- Coastal and High-Wind Zones: Its superior wind uplift and corrosion resistance make it an optimal solution for structures in coastal areas or regions prone to severe weather, including those in the petrochemical and industrial sectors where administrative or non-process buildings require robust, long-lasting enclosures.

- Industrial and Petrochemical (Administrative/Ancillary Buildings): While the primary production facilities in these sectors might use specialized industrial roofing, administrative offices, laboratories, and support buildings often require durable, aesthetically pleasing, and energy-efficient roofing. The corrosion resistance of the Galvalume core is particularly beneficial in corrosive industrial atmospheres, while its energy-saving properties contribute to overall facility efficiency.

- Water Supply & Drainage Infrastructure (Control/Service Buildings): Similar to petrochemical applications, the control rooms, pumping stations, and service buildings associated with water treatment and distribution often demand durable, low-maintenance roofing that can withstand environmental exposure and provide long-term protection for critical operational infrastructure.

In these diverse contexts, the Stone Coated Metal Roof Tile-Spain Tile consistently demonstrates advantages such as significant energy savings due to its cool roof properties, exceptional corrosion resistance from its multi-layered protection, and a visually impactful aesthetic that enhances property value and architectural integrity.

Vendor Comparison: Stone Coated Metal Roof Tile Solutions

When selecting a stone coated metal roof tile, discerning B2B clients evaluate vendors based on a comprehensive set of criteria, including material quality, certifications, warranty, customization capabilities, and post-sales support. While many manufacturers offer stone-coated metal roofing, variations in core materials, coating technologies, and service levels can significantly impact long-term project success. Below is a comparative overview:

| Feature/Criterion | Cool Roof Materials (Stone Coated Metal Roof Tile-Spain Tile) | Generic Competitor A (Standard Stone Coated Tile) | Generic Competitor B (Economy Metal Tile) |

|---|---|---|---|

| Base Steel Quality | Premium Galvalume (AZ50/AZ150), 0.45-0.55mm gauge | Galvalume (AZ50), 0.40-0.50mm gauge | Galvanized Steel or thinner Galvalume, 0.35-0.40mm gauge |

| Stone Granules | Natural basalt, ceramic-coated for fade resistance | Natural stone, basic pigmentation | Crushed quartz or lower-grade chips, prone to fading |

| Overglaze Protection | Advanced UV-resistant clear acrylic overglaze | Standard acrylic resin | Minimal or no overglaze, relies on stone coating |

| Certifications | ISO 9001, ASTM (UL 2218, D3161, E108), CE Mark | Basic local certifications | Limited/No major certifications |

| Warranty (Product) | 50-Year Limited Warranty | 30-Year Limited Warranty | 10-20 Year Basic Warranty |

| Customization Options | Extensive color matching, profile variations, accessory design | Limited standard colors/profiles | Very limited, off-the-shelf only |

| Technical Support | Comprehensive, including engineering, installation guides, design consultation | Standard product data sheets | Basic, sales-oriented support |

This comparison highlights the critical differences in quality and service levels available in the market. Investing in a high-quality Stone Coated Metal Roof Tile-Spain Tile solution from a reputable vendor ensures long-term performance, aesthetic integrity, and comprehensive project support.

Customized Solutions for Unique Project Requirements

Understanding that every B2B project has distinct architectural, environmental, and budgetary constraints, Cool Roof Materials offers comprehensive customized solutions for our Stone Coated Metal Roof Tile-Spain Tile. Our approach ensures that the roofing system perfectly integrates with the project's vision and performance demands.

Our Customization Capabilities Include:

- Color Matching and Blending: Beyond standard color palettes, we can develop custom stone granule blends to match specific architectural designs, historical requirements, or corporate branding. This ensures seamless integration with the building's overall aesthetic.

- Profile Adaptation: While the "Spain Tile" offers a classic profile, we can work with project architects to fine-tune aspects such as curve radius or ridge height to achieve a unique visual effect while maintaining structural integrity.

- Accessory Design: Custom-fabricated flashing, ridge caps, and ventilation components can be designed and supplied to ensure a watertight and aesthetically cohesive roofing system, regardless of roof complexity.

- Material Specification Adjustments: For projects in extremely harsh environments (e.g., highly corrosive industrial zones or severe hurricane regions), we can offer variations in steel gauge or specialized coating enhancements to further boost resilience.

- Logistics and Packaging: Tailored shipping solutions, including specialized crating or phased deliveries, can be arranged to meet project timelines and site constraints, minimizing handling and waste.

- Engineering and Technical Consultation: Our team of experts provides extensive pre-sale and post-sale technical support, including load calculations, wind uplift analysis, and detailed installation guidance, to ensure optimal performance and compliance with local building codes.

By offering these bespoke solutions, we empower our B2B clients to realize their architectural visions without compromising on the superior performance and longevity synonymous with our Stone Coated Metal Roof Tile-Spain Tile products.

Application Case Studies and Customer Experience

Our commitment to delivering high-performance roofing solutions is best demonstrated through real-world applications and the positive feedback from our esteemed clients. The Stone Coated Metal Roof Tile-Spain Tile has been successfully deployed in various challenging and architecturally significant projects globally.

Case Study 1: Luxury Coastal Resort - "The Azure Retreat"

- Challenge: A new luxury resort in a high-wind, corrosive coastal environment required a roofing solution that offered exceptional durability against saltwater spray and hurricane-force winds, while also providing the classic Mediterranean aesthetic. Traditional clay tiles proved too heavy and prone to breakage in such conditions.

- Solution: Over 15,000 square meters of Stone Coated Metal Roof Tile-Spain Tile in a custom sun-baked terracotta blend were installed. Its lightweight nature reduced structural loading, and the superior Galvalume coating provided robust corrosion resistance. The interlocking system ensured high wind uplift resistance.

- Outcome & Feedback: The project was completed ahead of schedule, with the roofing system exceeding local building code requirements for coastal construction. The resort management reported significantly reduced concerns about storm damage and praised the authentic aesthetic, stating, "The tiles not only withstand our harsh coastal weather but also perfectly capture the timeless Mediterranean charm we envisioned for our guests."

Case Study 2: Historic District Renovation - "The Old Town Hall"

- Challenge: A renovation project for a historic town hall, built in the early 20th century, required replacing a severely deteriorated clay tile roof. Strict heritage regulations demanded an exact replication of the original aesthetic, but a modern, more durable, and lighter solution was preferred to reduce maintenance and structural stress.

- Solution: Our technical team collaborated closely with the heritage architect to create a custom color blend and profile for the Stone Coated Metal Roof Tile-Spain Tile that precisely matched the original clay tiles. Its light weight was a key advantage, avoiding the need for costly structural reinforcement.

- Outcome & Feedback: The renewed town hall roof flawlessly integrated with the building's historic character, garnering praise from the local heritage board. The project manager noted, "The ability to perfectly replicate the look of centuries-old tiles while gaining the benefits of modern metal roofing was invaluable. It truly is a fusion of tradition and technology, giving us peace of mind for the next fifty years."

These case studies exemplify how our Stone Coated Metal Roof Tile-Spain Tile consistently delivers on its promises of performance, aesthetics, and long-term value, meeting the stringent demands of our B2B clientele.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

At Cool Roof Materials, transparency and comprehensive support are paramount. We are committed to building long-term relationships with our B2B partners by providing clear information and reliable service for our Stone Coated Metal Roof Tile-Spain Tile.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for Stone Coated Metal Roof Tile-Spain Tile orders?

- A: Standard orders typically have a lead time of 3-4 weeks from order confirmation to shipment, depending on volume and customization. Large or highly customized orders may require 5-7 weeks. We will provide a precise timeline upon order confirmation.

- Q: How does the warranty commitment work?

- A: We offer a 50-year limited warranty on our Stone Coated Metal Roof Tile-Spain Tile, covering manufacturing defects, material integrity, and significant loss of stone coating. A detailed warranty certificate is provided with each order, outlining specific terms and conditions.

- Q: Can these tiles be installed over an existing roof?

- A: In many cases, yes. Due to their lightweight nature, our tiles can often be installed directly over one layer of existing asphalt shingles, saving significant demolition and disposal costs. A structural assessment is recommended to confirm suitability for specific projects.

- Q: What maintenance is required for a Stone Coated Metal Roof?

- A: Maintenance is minimal. Regular inspections to clear gutters and check for debris are usually sufficient. The stone coating prevents moss and algae growth in most climates, and the robust finish does not require repainting or recoating.

- Q: Are the colors prone to fading over time?

- A: No. The natural basalt stone granules are ceramic-coated at high temperatures, ensuring permanent color. The clear acrylic overglaze provides additional UV protection, making our Stone Coated Metal Roof Tile-Spain Tile highly resistant to color fading, even under intense solar exposure.

Lead Time and Fulfillment

We operate with streamlined production and logistics to ensure efficient order fulfillment. Our lead times are managed proactively, and we communicate closely with clients regarding production status and shipping schedules. For large-scale projects, we offer coordinated delivery plans to align with on-site construction progress, minimizing storage requirements and potential delays.

Warranty Commitments

Our 50-year limited warranty reflects our unwavering confidence in the quality and longevity of our Stone Coated Metal Roof Tile-Spain Tile. This comprehensive warranty protects against material defects and performance issues, providing long-term assurance for your investment. Specific terms are provided in writing, covering performance under various environmental conditions.

Customer Support and After-Sales Service

Cool Roof Materials is dedicated to providing exceptional customer support throughout the entire project lifecycle and beyond. Our expert team is available for:

- Technical Assistance: Guidance on product specifications, installation best practices, and compatibility with building systems.

- Design and Engineering Support: Assistance with complex roof designs, ventilation strategies, and regulatory compliance.

- Logistics Coordination: Support for optimal shipping and delivery arrangements.

- After-Sales Inquiries: Prompt response to any questions or concerns post-installation.

Conclusion: The Future of Durable and Aesthetic Roofing

The demand for roofing solutions that merge unparalleled durability with sophisticated aesthetics is stronger than ever in the B2B construction landscape. The Stone Coated Metal Roof Tile-Spain Tile stands at the forefront of this evolution, offering a product that not only meets but often exceeds the most stringent performance requirements while delivering the timeless beauty of traditional Spanish architecture. Its advanced multi-layered composition, robust manufacturing process, and proven track record in diverse applications make it an optimal choice for architects, developers, and engineers seeking long-term value and peace of mind.

By integrating cutting-edge material science with a commitment to quality and comprehensive customer support, Cool Roof Materials ensures that the investment in our Stone Coated Metal Roof Tile-Spain Tile translates into enduring performance, enhanced energy efficiency, and a visually striking architectural statement for decades to come. As the construction industry continues to prioritize resilience, sustainability, and aesthetic integrity, this advanced roofing solution is poised to define the standard for future projects.

References

- ASTM International. (n.d.). ASTM Standards for Roofing Materials. Retrieved from www.astm.org

- Cool Roof Rating Council (CRRC). (n.d.). Cool Roof Product Directory and Research. Retrieved from www.coolroofs.org

- International Organization for Standardization (ISO). (n.d.). ISO 9001: Quality Management and ISO 14001: Environmental Management Systems. Retrieved from www.iso.org

- Metal Roofing Alliance. (n.d.). Benefits of Metal Roofing. Retrieved from www.metalroofing.com

- U.S. Department of Energy. (n.d.). Cool Roofs. Retrieved from www.energy.gov

-

Stone Coated Metal Roof Tile-Spain Tile: Durable, Elegant

NewsNov.10,2025

-

Roofing Granules for Sale – UV-Stable, Colorfast, Bulk

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Classic Tile: Durable & Light

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Nosen Tile | 50-Year Warranty

NewsNov.10,2025

-

Roofing Granules for Sale – UV-Stable, Colorfast, Bulk

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile Durable & Light

NewsNov.03,2025

Sep . 08, 2025 16:38 Back to list

Stone Coated Metal Roof Tile - Spain Tile Style & Durability

Advancing Roofing Solutions: The Rise of Stone Coated Metal Roof Tiles

The global construction and infrastructure sectors are continually seeking innovative materials that offer superior durability, aesthetic versatility, and long-term value. In this pursuit, advanced roofing solutions have become a critical focus for B2B decision-makers, architects, and engineers. Modern trends emphasize not just immediate cost-effectiveness but also lifecycle performance, environmental impact, and architectural integration. This demand has spurred significant advancements in roofing technology, moving beyond traditional materials to embrace solutions that offer enhanced resilience and sustainability.

One such innovation gaining substantial traction across diverse markets is the Stone Coated Metal Roof Tile-Spain Tile. This product category combines the robustness of steel with the aesthetic appeal of natural stone and traditional ceramic tiles, delivering a high-performance roofing solution suitable for a wide array of demanding applications. Its unique composition and manufacturing process address many of the challenges associated with conventional roofing materials, positioning it as a preferred choice for projects requiring both engineering excellence and refined visual appeal.

Industry Trends and Market Dynamics in High-Performance Roofing

Current industry trends in roofing are heavily influenced by the imperative for sustainable construction, stringent building codes, and evolving aesthetic preferences. Key drivers include:

- Energy Efficiency: A growing emphasis on cool roof technologies and materials with high solar reflectivity and thermal emissivity to reduce building cooling loads, in line with green building certifications like LEED and BREEAM.

- Durability and Resilience: Increased demand for roofing systems capable of withstanding extreme weather events, including high winds, heavy hail, and seismic activity, particularly in regions prone to such conditions.

- Longevity and Low Maintenance: Preference for roofing solutions that offer extended service life (50+ years) and require minimal maintenance, thereby reducing the total cost of ownership.

- Aesthetic Versatility: The need for materials that can replicate the traditional appearance of clay, slate, or wood shingles while offering superior performance, allowing for greater architectural freedom without compromising functionality.

- Environmental Responsibility: Focus on roofing products manufactured from recycled content, that are recyclable at the end of their life, and that contain fewer volatile organic compounds (VOCs).

The market for advanced metal roofing, including solutions like the Stone Coated Metal Roof Tile-Spain Tile, is projected to expand significantly, driven by these factors and the inherent advantages these products offer over conventional options. Specifically, stone-coated metal roofs address the demand for lightweight, high-strength, and aesthetically pleasing solutions that excel in performance under diverse environmental conditions.

Technical Specifications of Stone Coated Metal Roof Tile-Spain Tile

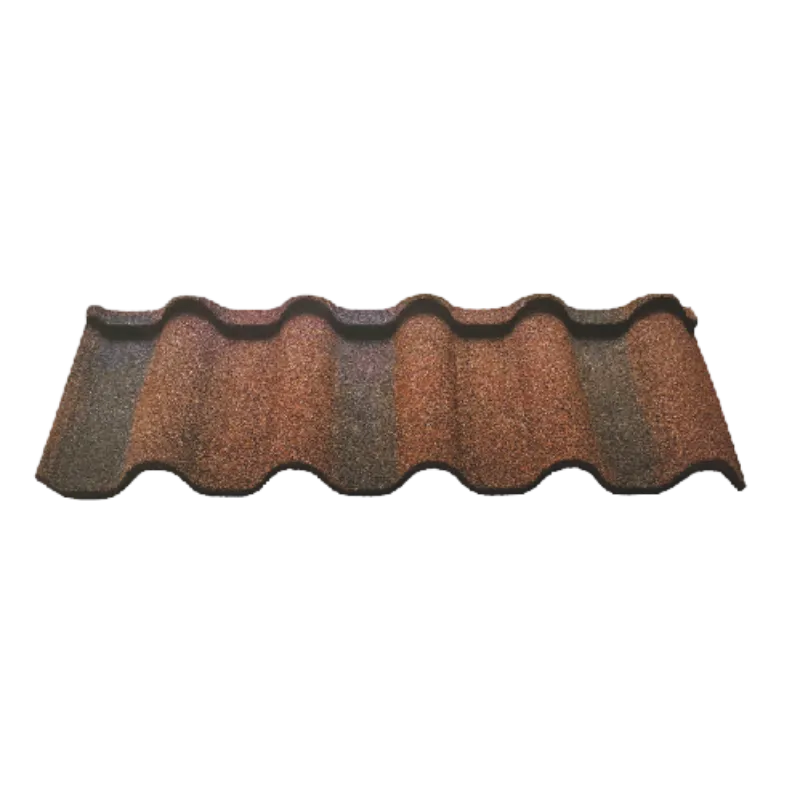

The Stone Coated Metal Roof Tile-Spain Tile is engineered for optimal performance and aesthetic fidelity, specifically designed to emulate the classic barrel-style ceramic tiles characteristic of Spanish architecture. Its multi-layered composition ensures exceptional durability and longevity.

Core Material and Coatings:

- Base Steel: High-grade Galvalume steel (Al-Zn coated steel), typically G90 or AZ50/AZ150, offering superior corrosion resistance compared to galvanized steel. Common gauges range from 26-gauge (0.45mm) to 24-gauge (0.55mm), providing an optimal balance of strength and flexibility.

- Surface Pre-treatment: Application of a chromate or non-chromate conversion coating to enhance adhesion for subsequent layers and further improve corrosion protection.

- Primer Coat: An acrylic or epoxy-based primer applied to both sides of the steel, ensuring maximum adhesion of the stone chip layer and acting as an additional barrier against moisture.

- Stone Chip Layer: Composed of natural basalt rock granules, crushed and coated with ceramic pigments, then bonded to the primer with a proprietary acrylic resin adhesive. These chips provide the tile's aesthetic finish, UV protection, and sound dampening qualities. The "Spain Tile" profile dictates a specific curvature and texture.

- Clear Acrylic Overglaze: A transparent acrylic layer applied over the stone chips, which seals the surface, enhances UV resistance, prevents color fading, and adds an extra layer of protection against environmental elements.

Performance Parameters:

| Parameter | Specification for Stone Coated Metal Roof Tile-Spain Tile |

|---|---|

| Material Composition | Galvalume Steel (AZ50/AZ150), Acrylic Resin, Natural Basalt Stone Granules, Acrylic Overglaze |

| Tile Dimensions (Approx.) | 1340mm x 420mm (Overall), 1250mm x 370mm (Effective Coverage) |

| Base Steel Thickness | 0.40mm - 0.55mm (Typical) |

| Weight (Per sq. meter) | 4.5 - 6.5 kg/m² (approx. 1/7th weight of traditional clay tiles) |

| Fire Rating | Class A (Non-combustible material when installed over non-combustible decking) |

| Wind Resistance | Up to 120 mph (190 km/h) / ASTM D3161 Class F, depending on installation methods |

| Hail Impact Resistance | Class 4 (UL 2218, highest rating) against 2-inch hail stones |

| UV Resistance | Excellent, maintains color stability over decades |

| Thermal Reflectivity | High, contributes to cool roof performance and energy savings |

| Lifespan | 50+ years, backed by long-term warranties |

These specifications underscore the advanced engineering behind Stone Coated Metal Roof Tile-Spain Tile, making it a robust and reliable choice for demanding roofing projects.

Detailed Manufacturing Process Flow of Stone Coated Metal Roof Tile-Spain Tile

The production of Stone Coated Metal Roof Tile-Spain Tile involves a meticulously controlled, multi-stage process, ensuring precision, consistency, and adherence to international quality standards such as ISO 9001 for quality management and relevant ASTM/ANSI standards for material performance. The process leverages advanced coil coating and profiling technologies.

Manufacturing Steps:

- Coil Feeding and Cleaning: High-quality Galvalume (Al-Zn alloy coated) steel coils, often 0.45mm to 0.55mm thick, are uncoiled and passed through a series of degreasing and cleaning baths to remove oils, dirt, and surface impurities, ensuring optimal adhesion for subsequent coatings.

- Pre-treatment (Chemical Conversion Coating): The cleaned steel surface undergoes a chemical conversion coating process (e.g., chromate or zirconium-based treatment). This creates a microscopic crystalline layer that enhances corrosion resistance and provides an excellent bonding surface for the primer.

- Primer Application and Curing: A specialized primer, typically an epoxy or acrylic-based resin, is precisely applied to both sides of the pre-treated steel sheet. This layer is crucial for adhesion of the stone granules and provides an additional protective barrier. The primed coil then passes through an oven for high-temperature curing, ensuring the primer is fully cross-linked and hardened.

- Stone Granule Application: While the primer coat is still wet and tacky, uniformly sized natural basalt stone granules, which have been ceramic-coated for permanent color, are electrostatically applied to the upper surface of the sheet. The electrostatic charge ensures even distribution and strong adhesion. This process is critical for achieving the desired aesthetic and protective qualities.

- Second Curing Cycle: The granule-coated sheet undergoes another curing cycle in a controlled oven environment. This step firmly bonds the stone chips to the primer and steel substrate, making them incredibly durable and resistant to shedding.

- Clear Acrylic Overglaze Application and Final Curing: A transparent acrylic overglaze is applied evenly over the stone-coated surface. This clear coat seals the granules, provides enhanced UV protection, prevents color fading, and adds an extra layer of weather resistance. A final curing stage ensures this protective layer is fully polymerized.

- Profiling/Pressing (Spain Tile Design): The now fully coated and cured flat sheets are fed into a specialized roll-forming and pressing machine. Here, through precise hydraulic pressing and profiling, the flat sheets are formed into the distinctive contoured shape of the Spain Tile, characterized by its elegant curves and ridges, which replicate traditional Spanish clay tiles. This step gives the product its final architectural form and structural rigidity.

- Quality Control and Packaging: Each finished tile undergoes rigorous quality inspections, checking for uniform coating, granule adhesion, dimensional accuracy, and color consistency. Tiles are then carefully stacked and packaged, often with protective interleaving, ready for shipment to project sites worldwide.

This elaborate manufacturing process, integrating material science with advanced engineering, results in a roofing product that not only meets but often exceeds industry standards for performance, durability, and aesthetic appeal. The adherence to standards like ISO 9001 and testing against ASTM E108 (fire resistance) and ASTM D3161 (wind resistance) ensures product reliability and consistency.

Technical Advantages and Performance Characteristics

The inherent design and material science behind Stone Coated Metal Roof Tile-Spain Tile confer a multitude of technical advantages that make it a superior choice for a broad spectrum of projects. These benefits directly translate into reduced lifecycle costs, enhanced structural integrity, and improved building performance.

- Exceptional Durability and Longevity: The Galvalume steel substrate combined with the multi-layer coating system offers unparalleled resistance to corrosion, UV degradation, and physical damage. With an anticipated service life of 50 years or more, it significantly outperforms traditional roofing materials.

- Superior Weather Resistance: Engineered to withstand extreme conditions, these tiles offer:

- High Wind Uplift: The interlocking panel design and robust fastening system enable resistance to wind speeds up to 120 mph (190 km/h), crucial for hurricane-prone regions.

- Hail Impact Resistance: Achieves a UL 2218 Class 4 rating, providing excellent protection against large hailstones and reducing the risk of structural damage and insurance claims.

- Fire Resistance: Rated as Class A fire resistant (when installed correctly), these tiles contribute significantly to building safety by preventing external flame spread.

- Freeze-Thaw Stability: The non-porous stone coating prevents water absorption, eliminating issues of cracking or delamination due to freeze-thaw cycles.

- Lightweight Design: At approximately 4.5-6.5 kg/m², these tiles are significantly lighter than concrete or clay tiles, reducing the structural load on the building. This can lead to cost savings in structural framing and foundation design for new construction and makes them an excellent option for re-roofing over existing structures without requiring extensive reinforcement.

- Energy Efficiency (Cool Roof Properties): The natural stone granules and proprietary acrylic overglaze contribute to high solar reflectivity and thermal emissivity. This helps to reduce heat absorption, lowering attic temperatures and subsequently decreasing air conditioning costs, particularly in warm climates.

- Acoustic Performance: The stone chip layer acts as an excellent sound dampener, significantly reducing noise from rain, hail, and external sources, enhancing indoor comfort.

- Aesthetic Versatility and Architectural Harmony: The "Spain Tile" profile authentically replicates the traditional and elegant appearance of Spanish clay tiles, available in a wide spectrum of colors to complement diverse architectural styles, from classic Mediterranean to contemporary designs.

- Environmental Sustainability: Made from high-recycled content steel and being 100% recyclable at the end of its long life, this product aligns with modern sustainable building practices and contributes to reduced environmental footprint.

These advantages solidify the position of Stone Coated Metal Roof Tile-Spain Tile as a premium, high-performance roofing solution, delivering exceptional value over its extended lifespan.

Figure 1: High-resolution depiction of Stone Coated Metal Roof Tile-Spain Tile showcasing its intricate profile and stone finish.

Application Scenarios and Target Industries

The unique combination of durability, aesthetic appeal, and high performance makes Stone Coated Metal Roof Tile-Spain Tile exceptionally versatile across numerous application scenarios and target industries. Its ability to provide both robust protection and architectural elegance broadens its scope beyond typical industrial applications to encompass commercial, residential, and institutional sectors.

Key Application Areas:

- High-End Residential Construction: For luxury homes, villas, and estates where a premium aesthetic is paramount, particularly those designed with Mediterranean, Spanish Colonial, or traditional European architectural themes. Its longevity and low maintenance appeal to discerning homeowners.

- Commercial and Hospitality Projects: Ideal for resorts, boutique hotels, restaurants, and retail centers seeking a distinctive, upscale appearance combined with long-term performance and brand consistency. Its resistance to harsh weather ensures continuous protection for commercial assets.

- Institutional and Public Buildings: Schools, universities, municipal buildings, and cultural centers can benefit from its durability, fire resistance, and minimal maintenance requirements, contributing to safe and aesthetically pleasing public infrastructure.

- Historical Renovations and Restorations: The ability of the Spain Tile profile to authentically mimic traditional clay tiles makes it an excellent choice for renovating historical properties or new construction in historic districts, preserving architectural heritage while integrating modern performance.

- Coastal and High-Wind Zones: Its superior wind uplift and corrosion resistance make it an optimal solution for structures in coastal areas or regions prone to severe weather, including those in the petrochemical and industrial sectors where administrative or non-process buildings require robust, long-lasting enclosures.

- Industrial and Petrochemical (Administrative/Ancillary Buildings): While the primary production facilities in these sectors might use specialized industrial roofing, administrative offices, laboratories, and support buildings often require durable, aesthetically pleasing, and energy-efficient roofing. The corrosion resistance of the Galvalume core is particularly beneficial in corrosive industrial atmospheres, while its energy-saving properties contribute to overall facility efficiency.

- Water Supply & Drainage Infrastructure (Control/Service Buildings): Similar to petrochemical applications, the control rooms, pumping stations, and service buildings associated with water treatment and distribution often demand durable, low-maintenance roofing that can withstand environmental exposure and provide long-term protection for critical operational infrastructure.

In these diverse contexts, the Stone Coated Metal Roof Tile-Spain Tile consistently demonstrates advantages such as significant energy savings due to its cool roof properties, exceptional corrosion resistance from its multi-layered protection, and a visually impactful aesthetic that enhances property value and architectural integrity.

Vendor Comparison: Stone Coated Metal Roof Tile Solutions

When selecting a stone coated metal roof tile, discerning B2B clients evaluate vendors based on a comprehensive set of criteria, including material quality, certifications, warranty, customization capabilities, and post-sales support. While many manufacturers offer stone-coated metal roofing, variations in core materials, coating technologies, and service levels can significantly impact long-term project success. Below is a comparative overview:

| Feature/Criterion | Cool Roof Materials (Stone Coated Metal Roof Tile-Spain Tile) | Generic Competitor A (Standard Stone Coated Tile) | Generic Competitor B (Economy Metal Tile) |

|---|---|---|---|

| Base Steel Quality | Premium Galvalume (AZ50/AZ150), 0.45-0.55mm gauge | Galvalume (AZ50), 0.40-0.50mm gauge | Galvanized Steel or thinner Galvalume, 0.35-0.40mm gauge |

| Stone Granules | Natural basalt, ceramic-coated for fade resistance | Natural stone, basic pigmentation | Crushed quartz or lower-grade chips, prone to fading |

| Overglaze Protection | Advanced UV-resistant clear acrylic overglaze | Standard acrylic resin | Minimal or no overglaze, relies on stone coating |

| Certifications | ISO 9001, ASTM (UL 2218, D3161, E108), CE Mark | Basic local certifications | Limited/No major certifications |

| Warranty (Product) | 50-Year Limited Warranty | 30-Year Limited Warranty | 10-20 Year Basic Warranty |

| Customization Options | Extensive color matching, profile variations, accessory design | Limited standard colors/profiles | Very limited, off-the-shelf only |

| Technical Support | Comprehensive, including engineering, installation guides, design consultation | Standard product data sheets | Basic, sales-oriented support |

This comparison highlights the critical differences in quality and service levels available in the market. Investing in a high-quality Stone Coated Metal Roof Tile-Spain Tile solution from a reputable vendor ensures long-term performance, aesthetic integrity, and comprehensive project support.

Customized Solutions for Unique Project Requirements

Understanding that every B2B project has distinct architectural, environmental, and budgetary constraints, Cool Roof Materials offers comprehensive customized solutions for our Stone Coated Metal Roof Tile-Spain Tile. Our approach ensures that the roofing system perfectly integrates with the project's vision and performance demands.

Our Customization Capabilities Include:

- Color Matching and Blending: Beyond standard color palettes, we can develop custom stone granule blends to match specific architectural designs, historical requirements, or corporate branding. This ensures seamless integration with the building's overall aesthetic.

- Profile Adaptation: While the "Spain Tile" offers a classic profile, we can work with project architects to fine-tune aspects such as curve radius or ridge height to achieve a unique visual effect while maintaining structural integrity.

- Accessory Design: Custom-fabricated flashing, ridge caps, and ventilation components can be designed and supplied to ensure a watertight and aesthetically cohesive roofing system, regardless of roof complexity.

- Material Specification Adjustments: For projects in extremely harsh environments (e.g., highly corrosive industrial zones or severe hurricane regions), we can offer variations in steel gauge or specialized coating enhancements to further boost resilience.

- Logistics and Packaging: Tailored shipping solutions, including specialized crating or phased deliveries, can be arranged to meet project timelines and site constraints, minimizing handling and waste.

- Engineering and Technical Consultation: Our team of experts provides extensive pre-sale and post-sale technical support, including load calculations, wind uplift analysis, and detailed installation guidance, to ensure optimal performance and compliance with local building codes.

By offering these bespoke solutions, we empower our B2B clients to realize their architectural visions without compromising on the superior performance and longevity synonymous with our Stone Coated Metal Roof Tile-Spain Tile products.

Application Case Studies and Customer Experience

Our commitment to delivering high-performance roofing solutions is best demonstrated through real-world applications and the positive feedback from our esteemed clients. The Stone Coated Metal Roof Tile-Spain Tile has been successfully deployed in various challenging and architecturally significant projects globally.

Case Study 1: Luxury Coastal Resort - "The Azure Retreat"

- Challenge: A new luxury resort in a high-wind, corrosive coastal environment required a roofing solution that offered exceptional durability against saltwater spray and hurricane-force winds, while also providing the classic Mediterranean aesthetic. Traditional clay tiles proved too heavy and prone to breakage in such conditions.

- Solution: Over 15,000 square meters of Stone Coated Metal Roof Tile-Spain Tile in a custom sun-baked terracotta blend were installed. Its lightweight nature reduced structural loading, and the superior Galvalume coating provided robust corrosion resistance. The interlocking system ensured high wind uplift resistance.

- Outcome & Feedback: The project was completed ahead of schedule, with the roofing system exceeding local building code requirements for coastal construction. The resort management reported significantly reduced concerns about storm damage and praised the authentic aesthetic, stating, "The tiles not only withstand our harsh coastal weather but also perfectly capture the timeless Mediterranean charm we envisioned for our guests."

Case Study 2: Historic District Renovation - "The Old Town Hall"

- Challenge: A renovation project for a historic town hall, built in the early 20th century, required replacing a severely deteriorated clay tile roof. Strict heritage regulations demanded an exact replication of the original aesthetic, but a modern, more durable, and lighter solution was preferred to reduce maintenance and structural stress.

- Solution: Our technical team collaborated closely with the heritage architect to create a custom color blend and profile for the Stone Coated Metal Roof Tile-Spain Tile that precisely matched the original clay tiles. Its light weight was a key advantage, avoiding the need for costly structural reinforcement.

- Outcome & Feedback: The renewed town hall roof flawlessly integrated with the building's historic character, garnering praise from the local heritage board. The project manager noted, "The ability to perfectly replicate the look of centuries-old tiles while gaining the benefits of modern metal roofing was invaluable. It truly is a fusion of tradition and technology, giving us peace of mind for the next fifty years."

These case studies exemplify how our Stone Coated Metal Roof Tile-Spain Tile consistently delivers on its promises of performance, aesthetics, and long-term value, meeting the stringent demands of our B2B clientele.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

At Cool Roof Materials, transparency and comprehensive support are paramount. We are committed to building long-term relationships with our B2B partners by providing clear information and reliable service for our Stone Coated Metal Roof Tile-Spain Tile.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for Stone Coated Metal Roof Tile-Spain Tile orders?

- A: Standard orders typically have a lead time of 3-4 weeks from order confirmation to shipment, depending on volume and customization. Large or highly customized orders may require 5-7 weeks. We will provide a precise timeline upon order confirmation.

- Q: How does the warranty commitment work?

- A: We offer a 50-year limited warranty on our Stone Coated Metal Roof Tile-Spain Tile, covering manufacturing defects, material integrity, and significant loss of stone coating. A detailed warranty certificate is provided with each order, outlining specific terms and conditions.

- Q: Can these tiles be installed over an existing roof?

- A: In many cases, yes. Due to their lightweight nature, our tiles can often be installed directly over one layer of existing asphalt shingles, saving significant demolition and disposal costs. A structural assessment is recommended to confirm suitability for specific projects.

- Q: What maintenance is required for a Stone Coated Metal Roof?

- A: Maintenance is minimal. Regular inspections to clear gutters and check for debris are usually sufficient. The stone coating prevents moss and algae growth in most climates, and the robust finish does not require repainting or recoating.

- Q: Are the colors prone to fading over time?

- A: No. The natural basalt stone granules are ceramic-coated at high temperatures, ensuring permanent color. The clear acrylic overglaze provides additional UV protection, making our Stone Coated Metal Roof Tile-Spain Tile highly resistant to color fading, even under intense solar exposure.

Lead Time and Fulfillment

We operate with streamlined production and logistics to ensure efficient order fulfillment. Our lead times are managed proactively, and we communicate closely with clients regarding production status and shipping schedules. For large-scale projects, we offer coordinated delivery plans to align with on-site construction progress, minimizing storage requirements and potential delays.

Warranty Commitments

Our 50-year limited warranty reflects our unwavering confidence in the quality and longevity of our Stone Coated Metal Roof Tile-Spain Tile. This comprehensive warranty protects against material defects and performance issues, providing long-term assurance for your investment. Specific terms are provided in writing, covering performance under various environmental conditions.

Customer Support and After-Sales Service

Cool Roof Materials is dedicated to providing exceptional customer support throughout the entire project lifecycle and beyond. Our expert team is available for:

- Technical Assistance: Guidance on product specifications, installation best practices, and compatibility with building systems.

- Design and Engineering Support: Assistance with complex roof designs, ventilation strategies, and regulatory compliance.

- Logistics Coordination: Support for optimal shipping and delivery arrangements.

- After-Sales Inquiries: Prompt response to any questions or concerns post-installation.

Conclusion: The Future of Durable and Aesthetic Roofing

The demand for roofing solutions that merge unparalleled durability with sophisticated aesthetics is stronger than ever in the B2B construction landscape. The Stone Coated Metal Roof Tile-Spain Tile stands at the forefront of this evolution, offering a product that not only meets but often exceeds the most stringent performance requirements while delivering the timeless beauty of traditional Spanish architecture. Its advanced multi-layered composition, robust manufacturing process, and proven track record in diverse applications make it an optimal choice for architects, developers, and engineers seeking long-term value and peace of mind.

By integrating cutting-edge material science with a commitment to quality and comprehensive customer support, Cool Roof Materials ensures that the investment in our Stone Coated Metal Roof Tile-Spain Tile translates into enduring performance, enhanced energy efficiency, and a visually striking architectural statement for decades to come. As the construction industry continues to prioritize resilience, sustainability, and aesthetic integrity, this advanced roofing solution is poised to define the standard for future projects.

References

- ASTM International. (n.d.). ASTM Standards for Roofing Materials. Retrieved from www.astm.org

- Cool Roof Rating Council (CRRC). (n.d.). Cool Roof Product Directory and Research. Retrieved from www.coolroofs.org

- International Organization for Standardization (ISO). (n.d.). ISO 9001: Quality Management and ISO 14001: Environmental Management Systems. Retrieved from www.iso.org

- Metal Roofing Alliance. (n.d.). Benefits of Metal Roofing. Retrieved from www.metalroofing.com

- U.S. Department of Energy. (n.d.). Cool Roofs. Retrieved from www.energy.gov