Aug . 18, 2025 03:00 Back to list

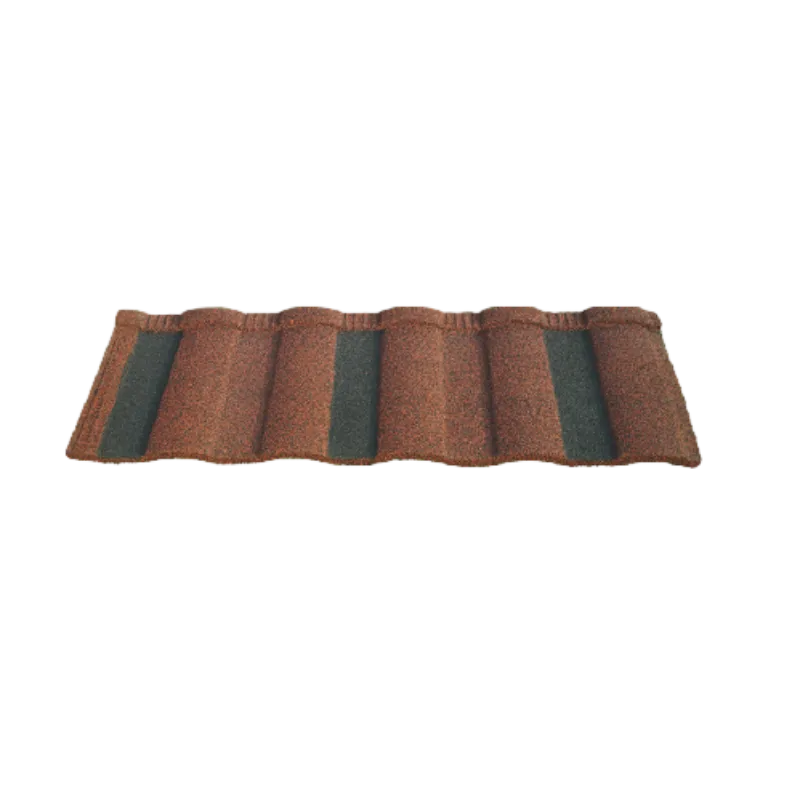

Roman Stone Coated Metal Roof Tile: Durable & Elegant Roofing

Navigating the Modern Roofing Landscape: The Rise of Stone Coated Metal Roof Tiles

The global roofing industry is undergoing a significant transformation, driven by an escalating demand for sustainable, durable, and aesthetically versatile materials. Traditional roofing solutions, while possessing their own merits, often fall short in addressing contemporary challenges such as extreme weather resilience, energy efficiency, and extended lifecycle requirements. In this evolving context, advanced materials like Stone Coated Metal Roof Tile-Roman Tile have emerged as a leading choice for discerning property owners and developers. These innovative tiles combine the robust strength of steel with the timeless appeal of natural stone, offering unparalleled protection and curb appeal. Industry trends point towards a growing preference for roofing solutions that not only provide superior structural integrity but also contribute to lower long-term maintenance costs and enhanced property value. The market is increasingly demanding products that offer certifications for wind resistance, fire safety, and impact resistance, ensuring peace of mind for both residential and commercial applications. Furthermore, the push for eco-friendly building practices is accelerating the adoption of materials with high recycled content and those that can contribute to reducing a building's carbon footprint through improved insulation properties and reduced urban heat island effects. Understanding these dynamics is crucial for any stakeholder in the construction and renovation sector seeking to invest in future-proof roofing solutions that align with both performance and sustainability objectives. This article delves into the specific characteristics, manufacturing prowess, and strategic advantages that position this particular tile as a premium offering in the competitive roofing market.

Unveiling the Sophisticated Manufacturing Process of Stone Coated Metal Roof Tiles

The superior performance of a Stone Coated Metal Roof Tile-Roman Tile is a direct result of its meticulous, multi-layered manufacturing process, which integrates advanced material science with precision engineering. The core of each tile begins with high-grade Galvalume steel (Aluminum-Zinc alloy coated steel), typically ranging from 0.40mm to 0.55mm in thickness. This substrate is chosen for its exceptional corrosion resistance, significantly outperforming traditional galvanized steel. The manufacturing journey commences with the precise cutting and forming of these steel sheets into the distinct Roman tile profile using specialized stamping and pressing machinery. Following this, the formed tiles undergo an extensive cleaning and degreasing process to ensure optimal adhesion for subsequent layers. A crucial step involves the application of an acrylic basecoat, which provides a protective foundation and further enhances corrosion resistance. This is followed by the embedding of natural stone granules, which are kiln-fired for color stability and durability. These granules are not merely decorative; they provide UV protection, noise reduction, and an additional layer of impact resistance. The final stages involve the application of a clear acrylic overglaze, which seals the granules, prevents fading, and adds a self-cleaning property, ensuring the tile retains its aesthetic appeal for decades. Quality control is rigorous throughout, with each batch subjected to tests verifying coating thickness, adhesion strength, and dimensional accuracy, adhering to international standards such as ISO 9001 for quality management and ASTM E108 for fire resistance. The typical service life for a properly installed Stone Coated Metal Roof Tile-Roman Tile is often warranted for 50 years or more, reflecting its robust construction and material resilience. This multi-stage process ensures a product that is not only visually appealing but also structurally sound and environmentally friendly, with a significant portion of its raw materials being recyclable.

Technical Parameters and Performance Metrics: A Deep Dive

For B2B decision-makers, understanding the precise technical specifications of a roofing material like the Stone Coated Metal Roof Tile-Roman Tile is paramount for informed investment. These tiles are engineered to meet stringent performance criteria across various environmental and structural demands. Key parameters include the substrate material, which is typically Z-in coated steel (Galvalume, composed of 55% aluminum, 43.4% zinc, and 1.6% silicon), offering superior sacrificial protection against corrosion compared to galvanized steel. The coating system consists of multiple layers: a primary protective film, an epoxy primer, the stone chip layer (often natural basalt or crushed granite), and a clear acrylic overglaze. The thickness of the steel core is a critical determinant of its structural integrity, commonly ranging from 0.40mm to 0.55mm, with some premium options reaching 0.60mm for enhanced rigidity in high-stress environments. Weight is another significant factor; these tiles are remarkably lightweight, typically 5-7 kg per square meter, which is considerably lighter than concrete or clay tiles (40-60 kg/sqm), reducing structural load on buildings and often negating the need for extensive roof reinforcement during renovation projects. This reduced weight also translates to lower transportation costs and easier installation. Furthermore, the interlock design of these tiles provides excellent wind uplift resistance, tested to withstand hurricane-force winds up to 120 mph (190 km/h) or more, compliant with ASTM D3161 Class F wind resistance standards. Their non-combustible steel base contributes to a Class A fire rating, the highest possible, making them highly resistant to external flame spread. The granular surface significantly reduces sound transmission, providing a quieter indoor environment during heavy rain or hail, and offers superior thermal performance by reflecting solar radiation, leading to potential energy savings in cooling costs, often contributing to 'Cool Roof' certifications.

| Parameter | Specification | Standard/Notes |

|---|---|---|

| Substrate Material | Galvalume Steel (55% Al-Zn alloy) | ASTM A792, JIS G3321 |

| Steel Thickness | 0.40mm - 0.55mm (Standard) | Customizable up to 0.60mm |

| Tile Dimensions (Nominal) | 1340mm x 420mm (effective coverage approx. 1290mm x 370mm) | Varies slightly by profile |

| Weight per sq. meter | ~5-7 kg/m² | Significantly lighter than traditional tiles |

| Fire Rating | Class A | ASTM E108, NFPA 256 |

| Wind Resistance | Up to 120 mph (190 km/h) | ASTM D3161 Class F |

| Impact Resistance | Class 4 (Hail Resistant) | UL 2218 |

| Service Life Warranty | 50+ Years | Manufacturer Specific |

| Thermal Reflectivity | High (Cool Roof certified) | Reduces heat absorption |

Versatility and Advantages in Diverse Application Scenarios

The inherent design flexibility and robust performance characteristics of the Stone Coated Metal Roof Tile-Roman Tile make it exceptionally suitable for a wide array of application scenarios, extending beyond conventional residential roofing. While ideal for suburban homes, luxury villas, and multi-family dwellings seeking a blend of classic aesthetics and modern durability, its advantages also translate powerfully into commercial and light industrial sectors. In regions prone to severe weather, such as coastal areas or locations experiencing frequent hailstorms, the tile's high wind uplift and Class 4 impact resistance (hail-resistant) offer critical protection, minimizing the risk of structural damage and expensive repairs. For commercial buildings, including offices, shopping centers, and hospitality establishments, the long service life of 50 years or more drastically reduces the total cost of ownership over the building's lifespan, eliminating frequent re-roofing cycles. Furthermore, the aesthetic consistency and variety of colors available for the Stone Coated Metal Roof Tile-Roman Tile enable architects and designers to maintain visual harmony across large developments or adhere to specific branding guidelines, which is particularly relevant for corporate campuses or themed resorts. Its lightweight nature is a significant advantage in renovation projects, as it often allows for installation over existing roofs without the need for costly tear-offs and structural reinforcement, saving both time and budget. Beyond its physical resilience, the energy-saving benefits are substantial; the reflective properties of the stone coating can significantly lower surface temperatures, reducing the heat island effect in urban environments and cutting down on air conditioning costs, aligning with green building initiatives and achieving 'Cool Roof' certifications, which can be a strong selling point for developers aiming for LEED or similar environmental accreditations.

Strategic Selection: Manufacturer Comparison and Customization

Selecting the right manufacturer for Stone Coated Metal Roof Tile-Roman Tile is a strategic decision that impacts project longevity, cost-efficiency, and overall satisfaction. While numerous suppliers exist, a comprehensive evaluation should extend beyond initial price points to encompass product quality, manufacturing certifications, warranty offerings, and customer support capabilities. Reputable manufacturers distinguish themselves through adherence to international standards like ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System), signaling a commitment to consistent quality and sustainable practices. A crucial differentiator lies in the quality of the Galvalume steel substrate and the acrylic resins used for coating; superior materials ensure enhanced corrosion resistance and UV stability, directly impacting the tile's service life and color retention. For example, some manufacturers utilize Australian-sourced stone granules, renowned for their colorfastness and durability, while others may opt for local alternatives. When comparing manufacturers, assess their track record of industry recognition, the depth of their technical support, and their capacity for customized solutions. Leading providers of Stone Coated Metal Roof Tile-Roman Tile often offer bespoke color matching, specialized profiles for unique architectural styles, and comprehensive accessory packages including ridge caps, valley flashings, and gable trims, ensuring a seamless and complete roofing system. For large-scale commercial or institutional projects, a manufacturer's ability to provide extensive project planning assistance, detailed installation guides, and even on-site technical supervision can be invaluable. Experienced suppliers also offer robust warranties, not just on the product itself but often on the coating performance, indicating their confidence in the material's long-term resilience against fading, chipping, and delamination. Finally, consider their logistical capabilities and typical lead times, which are critical for maintaining project schedules, especially for time-sensitive constructions.

Ensuring Trust and Authority: Certifications and Client Success

Establishing trust and demonstrating authority are paramount in the B2B sector, especially for critical building components like roofing. A reputable supplier of Stone Coated Metal Roof Tile-Roman Tile will readily provide comprehensive documentation of their product's compliance with national and international standards. This includes, but is not limited to, certifications from organizations like ISO (e.g., ISO 9001 for Quality Management), ASTM (American Society for Testing and Materials) for performance criteria like fire resistance (ASTM E108), wind uplift (ASTM D3161), and impact resistance (UL 2218). Evidence of independent laboratory testing for parameters such as salt spray corrosion, accelerated weathering, and adhesive strength further bolsters credibility. Many leading manufacturers are proud members of industry associations, participate in green building initiatives, and have extensive service histories spanning decades, indicating their sustained presence and reliability in the market. Beyond certifications, the true measure of a product's and a company's reliability lies in its real-world application and client feedback. Successful case studies showcasing the installation of Stone Coated Metal Roof Tile-Roman Tile on diverse projects – from large residential communities to commercial complexes – provide invaluable insights into its performance, durability, and aesthetic integration. Client testimonials highlighting positive experiences with product quality, technical support, and timely delivery add an authentic layer of trust. For instance, a major resort in a high-wind zone reported zero tile damage after a Category 3 hurricane due to the interlocking design and robust attachment system. Another commercial developer noted significant long-term energy savings attributed to the cool roof properties of the stone coating. These quantifiable outcomes and verified experiences serve as powerful endorsements, reassuring prospective clients of the product's proven efficacy and the manufacturer's commitment to excellence and customer satisfaction.

Frequently Asked Questions (FAQ) & Support Assurance

-

Q1: What makes Stone Coated Metal Roof Tile-Roman Tile a superior choice over traditional roofing materials?

Stone Coated Metal Roof Tile-Roman Tile offers a unique combination of exceptional durability, aesthetic versatility, and long-term cost-effectiveness. Unlike asphalt shingles that degrade under UV exposure and extreme temperatures, or clay/concrete tiles that are heavy and prone to breakage, these metal tiles are lightweight, highly resistant to fire (Class A), wind (up to 120 mph), and impact (Class 4 hail resistance). The natural stone granule coating provides superior UV protection, sound dampening during rain, and a timeless aesthetic that mimics traditional clay or concrete tiles without the associated weight or fragility issues. Their interlocking design prevents water penetration and uplift, ensuring superior performance in harsh weather conditions. Furthermore, the Galvalume steel core boasts outstanding corrosion resistance, ensuring the structural integrity of the tile for decades. This blend of performance attributes, coupled with a typically long warranty of 50 years or more, positions them as a future-proof investment, significantly reducing maintenance and replacement costs over a building's lifecycle.

-

Q2: What is the typical delivery schedule and how is product quality ensured during transit?

Our typical delivery schedule for standard orders of Stone Coated Metal Roof Tile-Roman Tile ranges from 3 to 6 weeks, depending on order volume, customization requirements, and destination logistics. For urgent or large-scale projects, we encourage clients to discuss specific lead times with our sales team to arrange expedited manufacturing or shipping solutions where feasible. To ensure product quality during transit, each tile batch undergoes rigorous pre-shipment inspection for dimensional accuracy, coating integrity, and overall appearance. Tiles are meticulously packaged using robust, export-grade materials, typically in secure crates or on reinforced pallets, designed to withstand the rigors of international shipping. Comprehensive protection includes moisture barriers and protective wrapping to prevent abrasion or environmental damage. We partner with reputable logistics providers who specialize in secure cargo handling, and all shipments are fully insured. Clients receive detailed tracking information and are provided with photographic evidence of packaging and loading processes to ensure transparency and peace of mind from our factory to their project site. Our commitment extends to providing full technical support for any queries during delivery and installation.

-

Q3: What kind of warranty and customer support can I expect for these roofing tiles?

We stand behind the quality and durability of our Stone Coated Metal Roof Tile-Roman Tile with a robust limited lifetime warranty, typically covering product defects for up to 50 years from the date of purchase. This warranty specifically addresses manufacturing defects, severe delamination of the stone coating, and structural integrity under normal environmental conditions. Furthermore, a separate fade-resistance warranty often guarantees the color stability of the stone granules for a significant period, typically 20-30 years, protecting the aesthetic appeal of your investment. Our commitment to customer satisfaction extends beyond the sale through comprehensive support channels. We provide detailed installation guides, technical specifications, and access to a team of experienced technical support specialists who can offer expert advice on product selection, installation best practices, and troubleshooting. For complex projects, on-site consultation or training can be arranged. Should any warranty claim arise, our dedicated customer service team ensures a prompt and transparent resolution process, upholding our reputation for reliability and client trust. Our goal is to ensure that your roofing solution performs optimally and maintains its beauty for decades, providing maximum value and peace of mind.

Conclusion: A Future-Proof Investment in Roofing Excellence

In summary, the adoption of Stone Coated Metal Roof Tile-Roman Tile represents a strategic move for B2B stakeholders seeking to combine long-term value, superior performance, and aesthetic flexibility in their construction projects. These tiles are engineered to address the evolving demands of modern architecture and the increasing challenges posed by climate change, providing unmatched resilience against severe weather while offering significant benefits in energy efficiency and reduced environmental impact. The meticulous manufacturing process, incorporating high-grade Galvalume steel and advanced stone coating technology, ensures a product with an extended service life exceeding 50 years, significantly reducing the lifecycle costs associated with roofing maintenance and replacement. Their lightweight nature facilitates easier installation and reduces structural load, making them ideal for both new constructions and renovation projects across diverse applications, from residential and commercial buildings to resorts and educational facilities. The quantifiable benefits, supported by adherence to rigorous international standards and comprehensive warranties, underscore their reliability and quality. Investing in Stone Coated Metal Roof Tile-Roman Tile is not merely purchasing a roofing material; it is securing a future-proof, high-performance building envelope that enhances property value, minimizes operational costs, and contributes positively to sustainable development goals. As the construction industry continues to prioritize durable, efficient, and aesthetically pleasing solutions, these advanced roofing tiles stand out as a prime example of innovation meeting practical demands, offering an intelligent and responsible choice for discerning developers and property owners globally.

References

- ASTM International. "Standard Test Methods for Fire Tests of Roof Coverings." ASTM E108 / E108M.

- UL (Underwriters Laboratories). "Standard for Impact Resistance of Prepared Roof Covering Materials." UL 2218.

- International Organization for Standardization. "Quality management systems — Requirements." ISO 9001:2015.

- Cool Roof Rating Council. "What is a Cool Roof?" Data and research on cool roof technologies.

- Metal Roofing Alliance. "Benefits of Metal Roofing." Industry data and comparative analyses.

-

Black Clay Tile: Durable, Sustainable Roofing for Modern Needs

NewsNov.24,2025

-

Red Clay Roof Tiles: Durable, Sustainable & Stylish Roofing Solutions

NewsNov.23,2025

-

Durable and Sustainable Ceramic Roofs: A Global Perspective on Design & Innovation

NewsNov.23,2025

-

Synthetic Clay Tile Roof – Durable, Eco-Friendly Roofing Solutions for Modern Buildings

NewsNov.22,2025

-

Expert Guide to Terracotta Tile Roof Restoration - Sustainable Preservation & Repair

NewsNov.21,2025

-

Planum Roof Tiles – Durable, Sustainable Flat Roofing Solutions for Global Needs

NewsNov.20,2025