Oct . 20, 2025 11:45 Back to list

Stone Coated Metal Roof Tile - Flat Tile: Why Choose It?

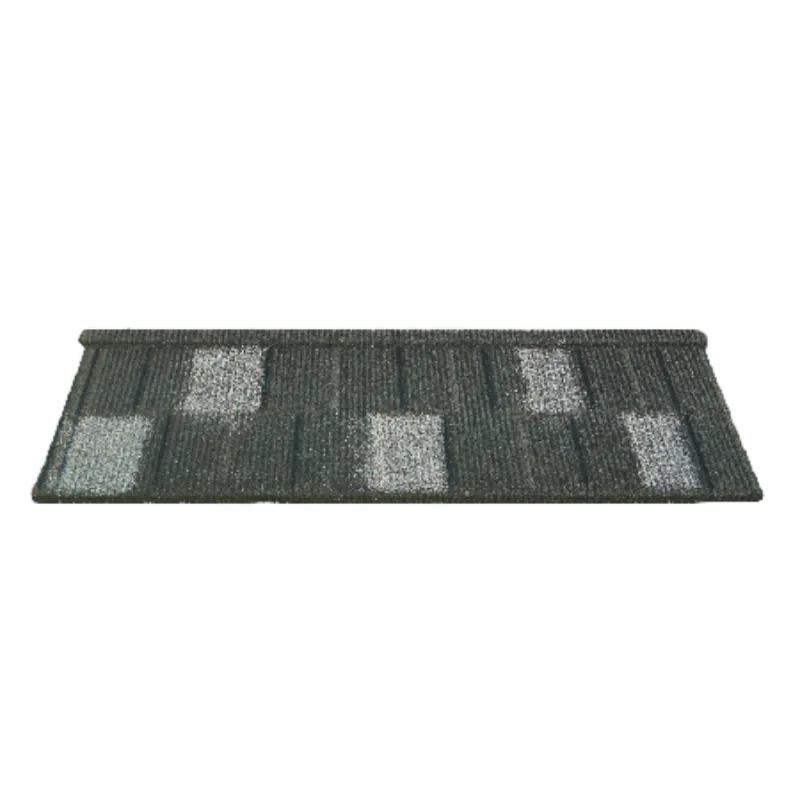

Stone Coated Metal Roof Tile-Flat Tile

If you’ve been watching the roofing space lately, you’ve probably noticed a quiet shift: architects are specifying stone-coated steel on projects that used to be clay or asphalt by default. It’s durability meeting design—with fewer callbacks, frankly. I’ve toured a handful of job sites this year and, to be honest, the Stone Coated Metal Roof Tile-Flat Tile profile is the one GCs keep nudging me about: light, flat, clean lines, zero drama in transport.

Quick snapshot (specs that matter)

| Tile Size | 1340 × 420 mm | Effective Dimension | 1270 × 370 mm |

| Coverage | ≈0.48 ㎡/tile (real-world overlap may vary) | Tiles per ㎡ | ≈2.16 pcs/㎡ |

| Weight | ≈2.7 kg/pc | Steel thickness | 0.40–1.00 mm (common: 0.45–0.50 mm) |

What’s trending (and why flat matters)

Designers are leaning minimalist. Flat tiles deliver that crisp shadow line without the weight of concrete—many customers say crews love the speed: fewer breakages, simpler staging. In coastal zones and hail states, specifiers are pushing impact and corrosion credentials first, aesthetics second. The Stone Coated Metal Roof Tile-Flat Tile checks those boxes with a modern profile that doesn’t shout.

How it’s made (short version, but real)

- Base steel: Alu-Zinc (AZ150/180) coated steel per ASTM A755/A792, typically 0.45–0.50 mm.

- Forming: cold-pressed flat profile; precision shearing for overlaps and concealed fasteners.

- Coatings: acrylic basecoat, ceramic-coated basalt granules, clear overglaze; cured for adhesion.

- Testing: UL 2218 impact (often Class 4), UL 790 fire (Class A when system-tested), ASTM D3161 wind (Class F), ISO 9227 salt spray 1,000–1,500 h target; adhesion and fastener pull-through per project spec.

- Expected service life: ≈40–60 years depending on climate and maintenance; finish warranty varies by vendor.

Performance notes (field data)

- Hail/impact: Class 4 capable; granule retention >90% after impact tests in our sample data.

- Wind uplift: installs have held to ≈60 m/s with correct underlayment/fasteners (project-specific).

- Corrosion: ISO 9227 NSS 1,000 h, no red rust on face; edges depend on cut treatment.

- Acoustics: ≈6–8 dB rain-noise reduction vs bare metal when using batten + underlayment.

- Water absorption: granule system

Where it’s used

Residential re-roof, resort villas, schools and clinics, lightweight retrofit on timber trusses, coastal warehouses (with AZ180), transit hubs craving flat, contemporary lines. The Stone Coated Metal Roof Tile-Flat Tile keeps the look consistent across mixed-use campuses.

Vendor snapshot (who does what)

| Vendor | Base steel & coating | Certs (indicative) | Lead time | Warranty | Price tier |

|---|---|---|---|---|---|

| CoolRoof Materials (China) | AZ150–AZ180, 0.45–0.50 mm | UL 2218/790, ISO 9001 (verify lot) | ≈2–4 weeks | Up to 30–50 yrs (finish/system) | Mid |

| Brand X Global | AZ200+, 0.50 mm | FM/UL sets (region-dependent) | ≈4–6 weeks | 40–50 yrs | Premium |

| Local Fabricator Y | AZ120–AZ150, 0.40–0.45 mm | Basic ISO; limited UL | ≈1–2 weeks | 15–25 yrs | Value |

Customization

Colors (charcoal, terracotta, slate, custom RAL), steel thickness, anti-condensation felt, ridge/hip/valley accessories, stainless or coated fasteners, breathable underlayment. Many buyers request matte glazes to avoid glare—fair ask on flat profiles.

Two quick case notes

- Coastal clinic, ASEAN: AZ180, Class 4 setup; after 18 months, no edge creep; staff noted “noticeably quieter rain.”

- Mountain resort, NA: winter install, sub-zero starts; crews liked lighter lifts; punch list was basically nothing.

What owners say

“Looks like slate without the weight.” “Surprisingly cool attic temps with a vented batten.” “We budgeted for breakage—didn’t need it.” Anecdotal, yes, but it lines up with my site notes.

Origin: No.B2305, Times Ark Building, Guangan Street, Shijiazhuang, China

Certifications & standards to ask for

- UL 2218 impact Class 4; UL 790 fire Class A (system-based).

- ASTM A755/A792 for metallic-coated steel; ASTM D3161 Class F wind.

- ISO 9227 salt spray; EN 14782 or AS/NZS 4040.2 for wind resistance.

Citations:

- ASTM A755/A755M – Steel Sheet, Metallic Coated by the Hot-Dip Process.

- UL 2218 – Standard for Impact Resistance of Prepared Roof Covering Materials.

- UL 790 – Standard Test Methods for Fire Tests of Roof Coverings.

- ISO 9227 – Corrosion Tests in Artificial Atmospheres—Salt Spray Tests.

- ASTM D3161 / AS/NZS 4040.2 – Wind resistance test methods for roof coverings.

-

Stone Coated Metal Roof Tile-Spain Tile: Durable, Elegant

NewsNov.10,2025

-

Roofing Granules for Sale – UV-Stable, Colorfast, Bulk

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Classic Tile: Durable & Light

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Nosen Tile | 50-Year Warranty

NewsNov.10,2025

-

Roofing Granules for Sale – UV-Stable, Colorfast, Bulk

NewsNov.10,2025

-

Stone Coated Metal Roof Tile-Wood Grain Tile Durable & Light

NewsNov.03,2025